Carbon Additve Low Ash sulphur for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

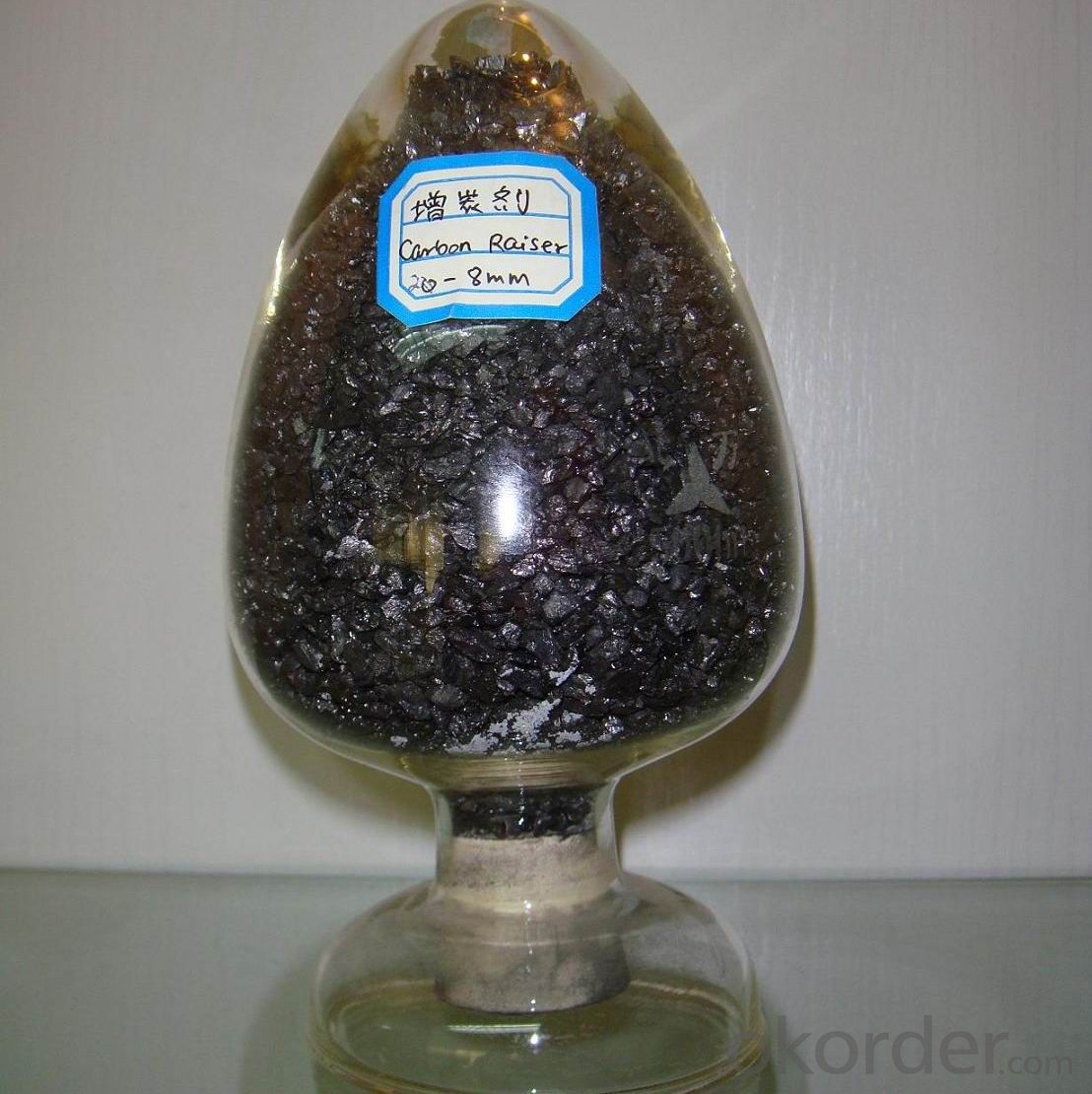

Place of Origin: Ningxia, China (Mainland)

Application: steel making

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

Specifications

Carbon Additve Low Ash Sulphur for Steelmaking

Carbon Additve low Ash,S,P

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

Structure

Carbon Additve Low Ash Sulphur for Steelmaking

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Feature

Carbon Additve Low Ash Sulphur for Steelmaking

Specifications (%): | ||||||

Grade | F.C | Ash | V.M | Moisture | S | Size |

CR-95 | ≥95 | <4 | <1 | <1 | <0.3 | 0-30mm |

CR-94 | ≥94 | <4 | <1 | <1 | <0.3 | |

CR-93 | ≥93 | <6 | <1 | <1 | <0.4 | |

CR-92 | ≥92 | <7 | <1 | <1 | <0.4 | |

CR-91 | ≥91 | <8 | <1 | <1 | <0.4 | |

CR-90 | ≥90 | <8.5 | <1.5 | <2 | <0.4 | |

Image

Carbon Additve Low Ash Sulphur for Steelmaking

FAQ:

Carbon Additve Low Ash Sulphur for Steelmaking

Why we adopt carbon additive?

Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation.

Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking.

Advantage:

Carbon Additve Low Ash Sulphur for Steelmaking

1.High quality and competitive price.

2.Timely delivery.

3.If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q: How does carbon dioxide affect global warming?

- Carbon dioxide is one of the primary greenhouse gases responsible for global warming. When released into the atmosphere, carbon dioxide traps heat from the sun and prevents it from escaping back into space, thus leading to an increase in the Earth's overall temperature. This phenomenon is often referred to as the greenhouse effect, where the Earth's atmosphere acts like the glass walls of a greenhouse, trapping heat and warming the planet. Human activities, such as burning fossil fuels for energy, deforestation, and industrial processes, have significantly increased the concentration of carbon dioxide in the atmosphere. These activities have released vast amounts of carbon dioxide that would have otherwise remained stored underground for millions of years. As a result, the concentration of carbon dioxide in the atmosphere has reached levels unseen for hundreds of thousands of years. The increase in carbon dioxide levels enhances the greenhouse effect and intensifies global warming. Rising temperatures have various adverse effects on the Earth's climate system. They contribute to the melting of polar ice caps and glaciers, leading to rising sea levels. This process threatens coastal communities and low-lying areas with increased risk of flooding and coastal erosion. Additionally, global warming disrupts weather patterns, leading to more frequent and severe extreme weather events, such as hurricanes, droughts, and heatwaves. Furthermore, global warming affects ecosystems and biodiversity. Many species are unable to adapt to rapid changes in temperature, resulting in habitat loss and an increased risk of extinction. Coral reefs, for example, are highly sensitive to temperature changes and are experiencing widespread bleaching events due to increased ocean temperatures. To mitigate the effects of carbon dioxide on global warming, efforts are being made to reduce greenhouse gas emissions. Transitioning to renewable energy sources, improving energy efficiency, reforestation, and implementing sustainable practices are some of the measures being taken to curb carbon dioxide emissions and mitigate the impacts of global warming.

- Q: What is carbon neutral certification?

- The process of carbon neutral certification involves evaluating and verifying organizations, products, or services to ensure they have a carbon footprint that equals zero. This requires taking significant measures to reduce greenhouse gas emissions and offsetting any remaining emissions through the purchase of carbon credits or investments in projects that remove carbon dioxide from the atmosphere. To achieve carbon neutrality, entities undergo a thorough assessment that measures their carbon emissions, sets reduction targets, implements initiatives to reduce their carbon footprint, and tracks progress. After reducing emissions as much as possible, any remaining emissions are offset by investing in verified projects such as reforestation, renewable energy, or energy efficiency projects that reduce greenhouse gases. Certification is conducted by an independent third-party organization to evaluate and verify carbon neutrality claims, ensuring transparency and credibility. Once certified, organizations or products can display the carbon neutral label to demonstrate their commitment to environmental sustainability and responsible carbon management. Carbon neutral certification is crucial as it offers a standardized and recognized method for organizations and products to showcase their dedication to combating climate change. It enables consumers and stakeholders to make informed choices by supporting entities that have taken concrete steps to reduce their carbon emissions and contribute to a more sustainable future. Moreover, carbon neutral certification encourages organizations to adopt sustainable practices and invest in environmentally positive projects, thus hastening the transition to a low-carbon economy.

- Q: Yes, I have a weapon, want to strengthen 11, said to be advanced furnace rock carbon, do not know how to get, look at the prawns pointing

- Pro, tell you an unfortunate news, out of the eighty furnace rock carbon, old horse recycling, burning their own boilers, and now we strengthen the use of colorless small crystal block, that is, the colorless small crystal block instead of the original furnace rock carbon.

- Q: What are the impacts of carbon emissions on human respiratory diseases?

- Carbon emissions have significant impacts on human respiratory diseases. The release of carbon dioxide and other greenhouse gases from various sources, such as burning fossil fuels and deforestation, contributes to air pollution. This pollution can lead to the exacerbation of respiratory conditions such as asthma, chronic obstructive pulmonary disease (COPD), and respiratory infections. Additionally, exposure to particulate matter and toxic chemicals emitted from carbon-based industries can increase the risk of developing respiratory diseases and worsen existing conditions. Overall, reducing carbon emissions is crucial to mitigate the adverse effects on human respiratory health.

- Q: What are the consequences of increased carbon emissions on public health systems?

- Public health systems are significantly affected by the increase in carbon emissions. One of the main consequences is the worsening of respiratory diseases like asthma, COPD, and bronchitis. These conditions are aggravated by the presence of fine particulate matter (PM2.5) and ground-level ozone, both of which can deeply penetrate the respiratory system. Furthermore, higher levels of carbon emissions are linked to a higher occurrence of cardiovascular diseases. The release of fine particulate matter and other pollutants from carbon-emitting sources can enter the bloodstream, leading to inflammation, oxidative stress, and the development of atherosclerosis. This can eventually result in heart attacks, strokes, and other cardiovascular complications. Additionally, the spread of infectious diseases is also influenced by climate change, which is driven by carbon emissions. The rise in temperatures and changes in precipitation patterns create favorable conditions for disease-carrying vectors like mosquitoes and ticks. This facilitates the transmission of diseases such as malaria, dengue fever, Lyme disease, and Zika virus. Moreover, extreme weather events and natural disasters associated with climate change can disrupt healthcare infrastructure and limit access to essential services, further impacting public health systems. Moreover, mental health is affected by the increase in carbon emissions as well. The degradation of the environment caused by carbon emissions contributes to feelings of anxiety, stress, and depression, often referred to as eco-anxiety or climate grief. The loss of biodiversity, destruction of natural habitats, and the general uncertainty about the future can have harmful effects on individuals and communities, requiring additional resources and support from public health systems. In conclusion, the consequences of increased carbon emissions extend far beyond the environment and have a profound impact on public health systems. They contribute to the prevalence of respiratory and cardiovascular diseases, facilitate the spread of infectious diseases, and affect mental health. It is crucial to address carbon emissions and adopt sustainable practices to mitigate these consequences and protect the well-being of individuals and communities.

- Q: How does carbon affect the formation of cyclones?

- Carbon does not directly affect the formation of cyclones. Cyclones, also known as hurricanes or typhoons, are formed through a complex interaction of various atmospheric and oceanic factors. Carbon, specifically carbon dioxide (CO2), is a greenhouse gas that contributes to global warming and climate change. It is important to note that while carbon dioxide concentrations in the atmosphere are increasing due to human activities, such as burning fossil fuels, it does not directly cause the formation of cyclones. However, climate change resulting from increased carbon dioxide levels does have an indirect influence on cyclone formation. Warmer temperatures due to climate change can lead to increased sea surface temperatures, which provide the energy necessary for cyclone formation and intensification. Higher temperatures also increase evaporation rates, leading to more moisture in the atmosphere that can fuel cyclone development. Furthermore, climate change can alter atmospheric conditions and circulation patterns, which may affect the frequency, intensity, and tracks of cyclones. However, the specific impact of carbon dioxide on cyclone formation and behavior is still an active area of research, and more studies are needed to fully understand the relationship between carbon dioxide and cyclones.

- Q: How does carbon impact the pH balance of oceans?

- Ocean acidification is caused by the absorption of carbon dioxide (CO2) released into the atmosphere by the oceans. This absorption leads to an increase in the acidity of the water, as the CO2 reacts with seawater to form carbonic acid. The carbonic acid then releases hydrogen ions, which further contribute to the acidity of the water. The increased acidity of the oceans has harmful consequences for marine life and ecosystems. Many marine organisms, including coral reefs, shellfish, and phytoplankton, rely on calcium carbonate to create their shells and skeletons. However, in more acidic waters, the availability of calcium carbonate decreases, making it difficult for these organisms to maintain their structures. This can result in weakened shells, stunted growth, and even death. Ocean acidification also affects the reproductive and physiological processes of marine organisms. For instance, it can interfere with the development of fish larvae and disrupt the ability of certain species to detect predators or locate food. Moreover, the increased acidity can harm the organisms that rely on these species for sustenance, thus causing a ripple effect throughout the food chain. Additionally, ocean acidification can have a profound impact on the overall health and functioning of marine ecosystems. Coral reefs, often referred to as the "rainforests of the sea," serve as habitats for a wide range of marine species. However, as the acidity of the oceans rises, coral reefs become more susceptible to bleaching and ultimately dying off. This loss of coral reefs would result in catastrophic consequences for the biodiversity and productivity of marine ecosystems. To summarize, the rise in atmospheric carbon dioxide levels leads to the absorption of CO2 by the oceans, resulting in ocean acidification. This process disturbs the pH balance of the oceans, making them more acidic. The increased acidity has detrimental effects on marine life, including the ability of organisms to build their structures, reproduce, and function within their ecosystems. It is imperative to address the issue of carbon emissions in order to mitigate the negative impacts of carbon on the pH balance of oceans and safeguard the health and integrity of marine ecosystems.

- Q: How does carbon dioxide affect waste management processes?

- Carbon dioxide (CO2) has a significant impact on waste management processes. One of the main ways in which it affects waste management is through the decomposition of organic waste. When organic waste, such as food scraps or yard waste, is sent to landfills, it undergoes anaerobic decomposition due to the lack of oxygen. This process produces methane (CH4), a potent greenhouse gas that contributes to climate change. Methane is approximately 25 times more effective at trapping heat in the atmosphere than carbon dioxide over a 100-year period. Therefore, the presence of carbon dioxide in waste management processes indirectly results in increased methane emissions, exacerbating the greenhouse effect. Moreover, carbon dioxide emissions from waste management activities can occur during the transportation and disposal of waste. The collection and transportation of waste to landfills or incineration facilities require the use of vehicles that typically run on fossil fuels, releasing carbon dioxide into the atmosphere. Additionally, waste incineration generates carbon dioxide emissions, as the combustion process produces CO2 as a byproduct. To mitigate the impact of carbon dioxide on waste management, several strategies can be employed. Firstly, reducing the amount of waste generated through waste reduction and recycling efforts can help minimize the need for landfilling or incineration, thereby reducing carbon dioxide emissions associated with waste management. Furthermore, implementing waste-to-energy technologies, such as anaerobic digestion or landfill gas capture, can help to harness the energy potential of organic waste, while simultaneously reducing methane emissions. Anaerobic digestion converts organic waste into biogas, which can be used to generate electricity or heat, while landfill gas capture systems collect methane emitted from landfills and use it for energy production. Lastly, transitioning to low-carbon transportation options, such as electric or hybrid vehicles, for waste collection and transportation can help reduce carbon dioxide emissions associated with waste management processes. In conclusion, carbon dioxide affects waste management processes by contributing to the production of methane during the decomposition of organic waste and through emissions generated during waste transportation and disposal. By implementing waste reduction strategies, waste-to-energy technologies, and transitioning to low-carbon transportation options, the impact of carbon dioxide on waste management can be minimized, resulting in more sustainable and environmentally friendly waste management practices.

- Q: What is the concept of carbon equivalent? What is the relationship between carbon equivalent and weldability?

- There are a lot of carbon equivalent indexes such as tensile strength, yield strength of carbon equivalent, carbon equivalent, welding carbon equivalent, and crack sensitivity index (which is essentially carbon equivalent).

- Q: What are the impacts of carbon emissions on the stability of tundra ecosystems?

- Carbon emissions have significant impacts on the stability of tundra ecosystems. As carbon dioxide levels increase in the atmosphere due to human activities, such as burning fossil fuels, it leads to global warming. Tundra ecosystems are particularly vulnerable to this warming trend. The increase in temperature causes the permafrost to thaw, resulting in the release of large amounts of stored carbon into the atmosphere as methane, a potent greenhouse gas. This feedback loop intensifies climate change, further impacting the stability of tundra ecosystems. Additionally, the warmer conditions allow for the expansion of shrubs and trees into the tundra, altering the delicate balance of plant species and disrupting the habitat for specialized tundra organisms. Overall, carbon emissions contribute to the destabilization of tundra ecosystems, leading to changes in biodiversity, permafrost degradation, and potential release of more greenhouse gases, exacerbating climate change.

Send your message to us

Carbon Additve Low Ash sulphur for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches