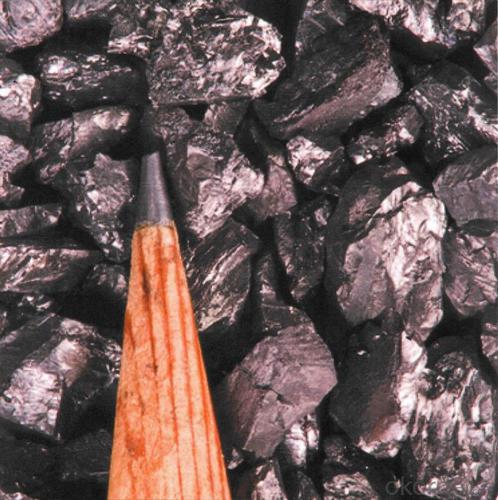

Calcined Anthracite Coal Low Sulphur for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

Specifications Calcined Anthracite Coal Low Sulphur for Steelmaking Carbon Additve low Ash,S,P Structure Calcined Anthracite Coal Low Sulphur for Steelmaking Shape: granule Dimensions: FC90-95% Product Type: Carbon Additive C Content (%): 90-95% MIN Working Temperature: - S Content (%): 0.5%MAX N Content (%): - H Content (%): 0.6%MAX Ash Content (%): 8.5%MAX Volatile: 2%MAX ADVANTAGE: low ash & sulfur COLOR: Black RAW MATERIAL: TaiXi anthracite Feature Calcined Anthracite Coal Low Sulphur for Steelmaking Specifications (%): Grade F.C Ash V.M Moisture S Size CR-95 ≥95 <4 <1 <1 <0.3 0-30mm CR-94 ≥94 <4 <1 <1 <0.3 CR-93 ≥93 <6 <1 <1 <0.4 CR-92 ≥92 <7 <1 <1 <0.4 CR-91 ≥91 <8 <1 <1 <0.4 CR-90 ≥90 <8.5 <1.5 <2 <0.4 Image Calcined Anthracite Coal Low Sulphur for Steelmaking FAQ: Calcined Anthracite Coal Low Sulphur for Steelmaking Why we adopt carbon additive? Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation. Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking. Advantage: Calcined Anthracite Coal Low Sulphur for Steelmaking 1.High quality and competitive price. 2.Timely delivery. 3.If any item you like. Please contact us. Your sincere inquiries are typically answered within 24 hours.

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

As buyer's request.

- Q: What are the properties of carbon fibers?

- Carbon fibers are known for their exceptional strength and stiffness, making them ideal for applications requiring high-performance materials. They possess a low density, corrosion resistance, and excellent thermal conductivity. Additionally, carbon fibers exhibit high resistance to fatigue and have a high tensile strength, allowing them to withstand extreme conditions. They are also chemically inert and have a low coefficient of thermal expansion, making them versatile for various industries such as aerospace, automotive, and sports equipment.

- Q: What are the effects of carbon emissions on the stability of mangrove forests?

- Carbon emissions have significant effects on the stability of mangrove forests. Mangrove forests are highly vulnerable to changes in climate, and increased carbon emissions contribute to global warming and climate change, which directly impact these ecosystems. One of the main effects of carbon emissions on mangrove forests is rising sea levels. As carbon dioxide is released into the atmosphere, it traps heat and contributes to the warming of the planet. This leads to the melting of polar ice caps and glaciers, causing sea levels to rise. The increased sea levels pose a threat to mangroves as they are adapted to grow in intertidal zones, where they are exposed to both saltwater and freshwater. With rising sea levels, mangroves may experience increased inundation, which can lead to their submergence and eventual death. Furthermore, carbon emissions also contribute to ocean acidification. As carbon dioxide dissolves in seawater, it forms carbonic acid, which alters the pH balance of the ocean. Mangroves rely on the ocean for their nutrient supply and reproductive processes. Ocean acidification can impede the availability of essential nutrients, such as nitrogen and phosphorus, which are vital for the growth and survival of mangroves. Additionally, the acidification of seawater can negatively affect the reproduction and development of mangrove species, leading to a decline in their population. Carbon emissions also contribute to changes in weather patterns, such as increased frequency and intensity of storms and hurricanes. Mangroves act as a natural barrier, protecting coastal areas from the destructive impacts of these extreme weather events. However, with intensified storms and hurricanes, the stability of mangrove forests is compromised. Strong winds, heavy rainfall, and storm surges can uproot or damage mangrove trees, disrupting their structure and reducing their ability to provide coastal protection. Lastly, carbon emissions contribute to the overall warming of the planet, which can lead to changes in precipitation patterns. Mangroves rely on a delicate balance of freshwater and saltwater for their survival. Alterations in precipitation patterns, such as prolonged droughts or increased rainfall, can disrupt this balance and negatively impact mangroves. Droughts can lead to water scarcity, causing mangroves to become stressed and more susceptible to diseases and pests. On the other hand, increased rainfall can lead to excessive amounts of freshwater, diluting the salinity of mangrove habitats and affecting their growth and reproduction. In conclusion, carbon emissions have detrimental effects on the stability of mangrove forests. Rising sea levels, ocean acidification, changes in weather patterns, and alterations in precipitation patterns all contribute to the degradation and loss of mangrove ecosystems. It is crucial to reduce carbon emissions and mitigate the effects of climate change to ensure the long-term survival and stability of mangrove forests.

- Q: How does carbon contribute to the strength of composite materials?

- The strength of composite materials is enhanced by carbon due to its distinctive properties and its ability to form robust chemical bonds. Carbon fibers or nanoparticles, when utilized, provide the composite material with both high tensile strength and stiffness. For reinforcing composite materials, carbon fibers are highly suitable due to their exceptional strength and lightweight nature. These fibers consist of tightly packed and aligned long, thin strands of carbon atoms. When incorporated into a matrix material like epoxy resin, the carbon fibers evenly distribute stress throughout the composite, thereby increasing its overall strength. The strength of composites is also influenced by the strong chemical bonds between carbon atoms. Carbon atoms have the capability to form covalent bonds that are both highly durable and stable. These bonds enable carbon to withstand significant levels of stress and deformation without fracturing, thereby making it an outstanding reinforcement material. In addition, carbon's high thermal conductivity facilitates efficient heat transfer away from the composite material, thereby preventing overheating and potential damage. This property is particularly significant in applications that involve temperature fluctuations or require high heat dissipation, such as the aerospace or automotive industries. In conclusion, carbon's unique properties, such as its high tensile strength, stiffness, strong chemical bonds, and thermal conductivity, play a crucial role in enhancing the strength and performance of composite materials.

- Q: How is carbon used in the production of rubber?

- Due to its unique properties and ability to enhance the overall quality and performance of rubber products, carbon finds widespread use in rubber production. An essential component in rubber manufacturing, carbon black is formed when hydrocarbons are incompletely burned. To enhance the strength, durability, and resistance to wear and tear of rubber, carbon black is added to rubber formulations. Acting as a reinforcing agent, it increases tensile strength and abrasion resistance by interlocking with the rubber polymer chains and fortifying the material's overall structure, making it more resilient. Moreover, carbon black improves the electrical conductivity of rubber, making it valuable in applications that require conductivity. It also enhances the rubber's resistance to degradation from exposure to sunlight by boosting its UV resistance. Furthermore, carbon black can enhance the color and appearance of rubber products, imparting a deep black hue. Furthermore, carbon black can serve as a filler in rubber compounds, reducing production costs while maintaining or even improving the rubber's mechanical properties. By substituting part of the more expensive rubber polymer with carbon black, manufacturers can achieve cost savings without compromising the desired performance characteristics of the rubber. In conclusion, carbon plays a vital role in rubber production by enhancing its strength, durability, conductivity, UV resistance, and appearance. Rubber products would lack the necessary properties for their intended applications without carbon.

- Q: What is carbon steel, carbon manganese steel?

- Compared with other kinds of steel, carbon steel is the earliest, low cost, wide performance range and the largest amount. For nominal pressure PN is less than or equal to 32.0MPa, temperature of -30-425 water, steam, air, hydrogen, ammonia, nitrogen and petroleum products such as medium. Commonly used grades are WC1, WCB, ZG25 and high quality steel 20, 25, 30 and low-alloy structural steel 16Mn

- Q: What are the different types of carbon-based food additives?

- The food industry commonly utilizes various carbon-based food additives for different purposes. These additives have multiple functions, including enhancing flavor, improving texture, and extending the shelf life of food products. Here are a few examples: 1. Activated Carbon: Used as a food coloring agent, activated carbon is a porous form of carbon with high adsorption properties. It is often employed to give black color to specific food and beverages, such as black food coloring or black lemonade. 2. Carbon Black: Also known as vegetable carbon or vegetable black, this additive is derived from charcoal and serves as a natural food coloring agent. It is frequently utilized to provide a dark black or grey color to foods like black licorice, ice cream, and bakery products. 3. Carbon Dioxide: Though not directly added as an additive, carbon dioxide gas is utilized in food processing and packaging to prolong the shelf life of certain products. It is commonly present in carbonated beverages to create the characteristic fizz and is also used in modified atmosphere packaging to preserve the freshness of specific foods. 4. Carbonated Water: This refers to carbon dioxide gas dissolved in water, resulting in carbonic acid. Carbonated water is often used as a base for soft drinks and beverages, imparting effervescence and a refreshing taste. 5. Carbonates: Calcium carbonate and sodium carbonate are examples of carbonates used as acidity regulators in food products. They aid in maintaining the pH balance and controlling the acidity of certain foods, such as canned vegetables, fruit preserves, and pickles. 6. Carbon-based Preservatives: Sorbic acid and propionic acid, among other carbon-based additives, act as preservatives to prevent the growth of molds, bacteria, and yeasts in food products. They contribute to extending the shelf life of products like bread, cheese, and processed meats. It is essential to note that while carbon-based food additives are generally considered safe for consumption, it is advisable to read food labels and seek guidance from professionals, such as dietitians or healthcare providers, if any concerns or specific dietary restrictions arise.

- Q: Carbon steel with carbon steel, carbon steel yuan yuan is the same? The trouble to know the answer urgently

- Nor can we see carbon steel and carbon circle are called carbon circle. If the carbon steel and carbon circle are called carbon that are circular steel.

- Q: What do you mean by carbon fiber for 1K, 3K, 6K and 12K?

- This is the specification of carbon fiber, refers to the number of filaments in carbon fiber tow, 1K=1000 (root), 3K=3000 (root), 6K=6000 (root), 12K=12000 (root). At the same time, 1K, 3K, 6K, and 12K are also called small tow.The relationship between the properties of carbon fibers and the number of filaments is described below:According to the number of carbon fiber bundle of carbon fiber filaments can be divided into small tow and tow two. Compared with small tow, the disadvantage of large tow is that when the structure of the plate is made, the tow should not spread out, resulting in the increase of the monolayer thickness, which is not conducive to the structural design. In addition, large tow carbon fiber adhesion, wire breaking phenomenon more, which makes the strength and stiffness of the affected, a decrease in performance, the performance of dispersion will be larger. Aircraft, spacecraft generally only a small tow carbon fiber, so the small tow carbon fiber is also known as the "space" of carbon fiber, large tow carbon fiber is known as the "industrial grade carbon fiber.But large tow production costs than small tow low, and with the progress of the production technology, people familiar with the structure of the carbon fiber material, large tow carbon fiber more and more stringent requirements for reliability field. In this way, between the small and large tow tow distinguish changes, such as earlier in the number of single tow 12000 (12K) as the dividing line, but the number of carbon fiber 1K~24K is divided into small bundles, rather than 48K designated as large tow. While the Airbus Company has begun to use 24K carbon fibers in the manufacture of A380 super large aircraft, it is estimated that as the technology advances, the line between the small tow and the big tow will push up.

- Q: What are the effects of carbon emissions on freshwater systems?

- Carbon emissions have significant effects on freshwater systems. Increased carbon dioxide levels in the atmosphere lead to a rise in global temperatures, which in turn affects freshwater ecosystems. Warmer water temperatures can disrupt the delicate balance of aquatic life, leading to the decline of certain species, including fish and other organisms that depend on specific temperature ranges. Additionally, carbon emissions contribute to ocean acidification, which ultimately affects freshwater systems through interconnected hydrological cycles. Acidic waters can harm freshwater organisms, deplete their food sources, and disrupt the overall health of these ecosystems. Overall, carbon emissions have a detrimental impact on freshwater systems, threatening their biodiversity and ecological stability.

- Q: What is the structure of graphite, another form of carbon?

- Graphite possesses a unique carbon form with a structure that differs from diamond or amorphous carbon. It showcases layers of carbon atoms arranged in a hexagonal lattice. Covalent bonds connect each carbon atom to three neighboring carbon atoms, resulting in a two-dimensional sheet-like structure. Within each layer, the carbon atoms bond together through robust covalent bonds, creating a flat network. The carbon-carbon bonds in graphite are notably stronger than typical single bonds, ensuring the structure's high stability. The hexagonal lattice arrangement of carbon atoms forms a honeycomb-like pattern, giving graphite its characteristic appearance. The layers in graphite remain cohesive due to weak van der Waals forces, enabling easy sliding between them. This attribute grants graphite its lubricating properties and allows it to leave marks on paper when used as a pencil lead. Additionally, the arrangement of carbon atoms in graphite contributes to its exceptional electrical conductivity. The structure's delocalized electrons can move freely along the layers, facilitating the flow of electric current. This feature renders graphite valuable in various applications, including electrical components, electrodes, and as a lubricant in high-temperature environments. In conclusion, graphite's structure comprises layers of carbon atoms organized in a hexagonal lattice. These layers are bonded through strong covalent bonds within each layer and held together by weak van der Waals forces. This distinctive structure grants graphite its unique properties, such as its lubricating nature, electrical conductivity, and versatility in diverse industrial applications.

Send your message to us

Calcined Anthracite Coal Low Sulphur for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords