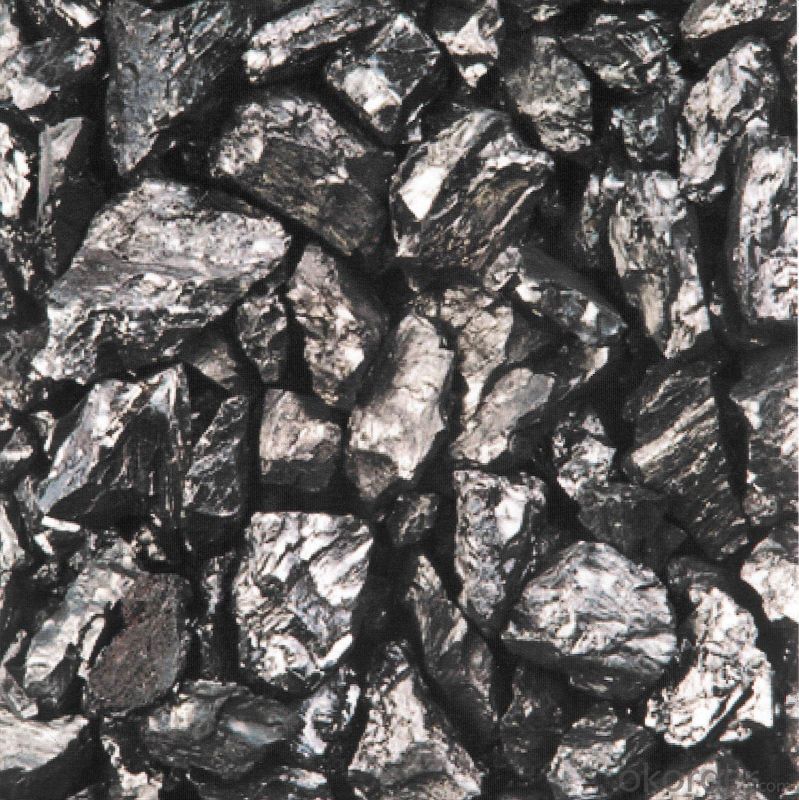

Carbon Additive Low Ash Low Sulphur Description

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

Specifications

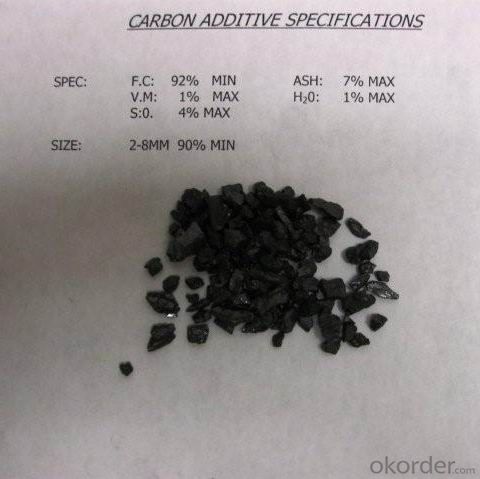

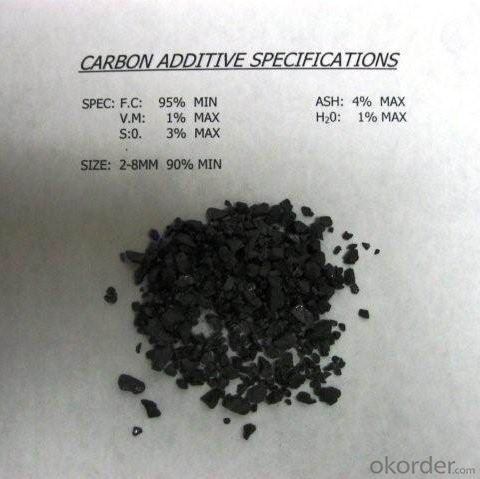

Carbon Additive Low Ash Low Sulfur Specifications

Carbon Additve low Ash,S,P

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

Structure

Carbon Additive Low Ash Low Sulfur Specifications

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

..

Feature

Carbon Additive Low Ash Low Sulfur Specifications

| Specifications (%): | ||||||

| Grade | F.C | Ash | V.M | Moisture | S | Size |

| CR-95 | ≥95 | <4< td=""> | <1< td=""> | <1< td=""> | <0.3< td=""> | 0-30mm As buyer's request. |

| CR-94 | ≥94 | <4< td=""> | <1< td=""> | <1< td=""> | <0.3< td=""> | |

| CR-93 | ≥93 | <6< td=""> | <1< td=""> | <1< td=""> | <0.4< td=""> | |

| CR-92 | ≥92 | <7< td=""> | <1< td=""> | <1< td=""> | <0.4< td=""> | |

| CR-91 | ≥91 | <8< td=""> | <1< td=""> | <1< td=""> | <0.4< td=""> | |

| CR-90 | ≥90 | <8.5< td=""> | <1.5< td=""> | <2< td=""> | <0.4< td=""> | |

Image

Carbon Additive Low Ash Low Sulfur Specifications

FAQ:

Why we adopt carbon additive?

Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation.

Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking.

Advantage:

Carbon Additive Low Ash Low Sulfur Specifications

1.High quality and competitive price.

2.Timely delivery.

3.If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q: Which is better, 13 and 14 carbon breath tests?

- Two kinds of carbon synthesis conditions are different, the instruments are not the same, so lead to price differences

- Q: Appearance, hardness, electrical conductivity, use of carbon 60

- C60 is a molecule composed of 60 carbon atoms in the molecule, it is like football, so also known as footballene (C60. This material is composed of C60 molecules, rather than by the atoms.) C60 is simply made of carbon atoms with stable molecules, it has 60 vertices and 32 sides. The 12 is Pentagon and 20 hexagon. Its molecular weight is about 720.

- Q: What are the industrial uses of diamonds?

- Diamonds have a wide range of industrial uses due to their exceptional physical properties. One of the most common industrial uses of diamonds is in the manufacturing of cutting and grinding tools. Diamond-tipped saw blades, drill bits, and grinding wheels are highly sought after for their superior hardness and abrasion resistance. These tools are used to cut and shape hard materials like concrete, ceramics, and metals. Diamonds also find extensive applications in the electronics industry. They are used as heat sinks in high-power electronic devices and as abrasive materials for polishing and lapping electronic components. The thermal conductivity of diamonds allows them to efficiently dissipate heat, making them ideal for electronic devices that generate a lot of heat during operation. Furthermore, diamonds are used in the production of specialized windows, lenses, and prisms for various scientific and industrial applications. Their optical properties, such as high refractive index and low dispersion, make them valuable for creating precision optics used in lasers, spectroscopy, and telecommunications. In addition, diamonds have found niche uses in the medical and dental fields. They are used in surgical tools such as scalpels and dental drills due to their exceptional hardness and ability to retain sharp edges. Diamond coatings are also applied to medical implants and prosthetics to improve their wear resistance and biocompatibility. Lastly, diamonds are utilized in the oil and gas industry for drilling and exploration purposes. Diamond drill bits are capable of penetrating extremely hard rock formations, making them essential for extracting oil and natural gas from deep beneath the Earth's surface. Overall, the industrial uses of diamonds are vast and diverse, ranging from cutting and grinding tools to electronics, optics, medicine, and even oil and gas exploration. The unique properties of diamonds make them indispensable in numerous industrial applications, contributing to advancements in various fields.

- Q: How is carbon used in the production of adhesives?

- Carbon is used in the production of adhesives in several ways. One common method involves the use of carbon black, which is a fine powder made from the incomplete combustion of hydrocarbon fuels. Carbon black is added to adhesives to improve their strength, durability, and resistance to UV radiation. It acts as a reinforcing agent, increasing the adhesion and cohesion properties of the adhesive. Additionally, carbon fibers are sometimes incorporated into adhesives to further enhance their strength and mechanical properties. These fibers are made by heating and stretching synthetic fibers or natural materials like rayon or petroleum pitch. When added to adhesives, carbon fibers provide increased tensile strength and stiffness, making them ideal for applications that require high-performance adhesives. Moreover, carbon-based polymers, such as epoxies and polyesters, are widely used in adhesive formulations. These polymers are created through chemical reactions involving carbon-based monomers. They offer excellent bonding properties, high resistance to heat and chemicals, and can be tailored to specific application requirements. Furthermore, carbon-based resins can be modified with other additives and fillers to achieve specific characteristics, such as flexibility, impact resistance, or flame retardancy. In summary, carbon is utilized in the production of adhesives through the incorporation of carbon black, carbon fibers, and carbon-based polymers. These materials significantly enhance the strength, durability, and other properties of adhesives, making them suitable for a wide range of applications in industries such as automotive, construction, electronics, and aerospace.

- Q: How does carbon affect the formation of haze?

- Carbon plays a significant role in the formation of haze due to its ability to interact with other pollutants and atmospheric conditions. When carbon-containing compounds, such as fossil fuel emissions or organic matter from wildfires, are released into the atmosphere, they undergo chemical reactions with gases like nitrogen oxides and volatile organic compounds. These reactions result in the formation of secondary organic aerosols (SOAs), which are tiny particles suspended in the air. These SOAs can contribute to haze formation by scattering and absorbing sunlight, reducing visibility and creating a hazy appearance. The carbon particles can also serve as condensation nuclei, attracting other pollutants and water vapor, leading to the formation of larger particles and subsequently haze. Additionally, the interaction between carbon and atmospheric moisture can result in the formation of secondary organic aerosol particles that contribute to haze formation. Furthermore, carbon particles can contribute to the formation of photochemical smog, which is a type of haze characterized by high levels of ozone. Carbon-containing pollutants can react with sunlight and other pollutants, leading to the production of ozone. This ozone, along with other pollutants, can contribute to the formation of haze and reduce air quality. In summary, carbon affects the formation of haze by contributing to the formation of secondary organic aerosols, serving as condensation nuclei, and promoting the production of ozone. Understanding the role of carbon in haze formation is crucial for implementing effective air pollution control measures and mitigating the impacts of haze on human health and the environment.

- Q: What is latent carbon?

- If there is already one or more chiral centers in the molecule, the chiral center of the molecule will result in a non enantiomer, for example:The C-2 2- hydroxybutyric acid is chiral, is a chiral molecule.C-3 is connected with the two hydrogen atoms of the same and two not the same group, it is a potential chiral carbon atoms. When a hydrogen atom on the C-3 is a different from the other three atoms or groups (such as OH) instead, it generates a new chiral carbon atom. This new chiral carbon atom has two opposite configuration, and the chiral carbon atoms of the original configuration is the same, so the product is replaced by the diastereoisomers, their output is not equal, is often far away.This is not directly after separation of chiral molecules in latent chiral carbon atoms into chiral carbon atoms, and generate different amounts of stereoisomers called "chiral synthesis" (chiral synthesis), also known as "asymmetric synthesis" (asymmetric synthesis).

- Q: Isotopes of carbon

- There are three kinds of nature of carbon isotope, stable isotopes of 12C, 13C and 14C 14C of the radioactive isotope, the half-life is 5730 years, the application of 14C mainly has two aspects: one is the determination of biological death in archaeology, radioactive dating method; the two is labeled with 14C compound as a tracer, exploration the micro motion of chemistry and life science.

- Q: Is badminton all good as carbon or aluminum carbon? Does carbon fiber on the Internet mean total carbon?

- Products using what material is an important factor to determine its price under the table, can let you understand the properties of several materials and approximate cost: the hardness of the material strength shock probably cost RMB $/KG high strength carbon fiber carbon fiber (HighModulusGraphite) 874157 (Graphite/ Carbon) 58445 (Aluminum) 24115 Aluminum Alloy wood (wood) 11104 must pay attention to in the choice of the racket, don't put the whole aluminum frame carbon rod racket mistaken for full carbon badminton racket. General note the label on the racket, should be able to distinguish, if not sure, I have three methods that can be used, one hand touch frame Aluminum Alloy good thermal conductivity due to the frame model is cool and the carbon frame is warm. But look at the groove on the racket frame, the aluminum frame is concave inside the shallow arc, and the carbon frame is an inner concave trapezoid. Three is to feel the weight, the aluminum frame's racket head is obviously biased. As the transition from aluminum frame to full carbon product, I feel that the price is high and the performance is low, it is not a good choice.

- Q: What are the different types of carbon-based food additives?

- Some examples of carbon-based food additives include caramel color, vegetable carbon (activated charcoal), and carbon black. These additives are used for various purposes such as coloring, flavor enhancement, and texture improvement in food products.

- Q: The difference between double offset paper and carbon free printing paper

- The use of the two is entirely different.Double offset paper is a printing paper. It is a higher quality printing paper. The contrast, flexibility and surface strength have higher requirements, and the acidity and basicity of the paper should be close to neutral or weak alkaline.Double gummed paper refers to printing paper, also called offset paper. Culture, printing paper paper one of the typical representative, in the business of two-sided offset paper (two-sided offset paper) commodity name, the old road / Taiwan area with a ream of paper, also called die rough paper.Carbon free copy is just typing paper and coating. Paint is divided into two kinds, one kind of colored, one kind of colorless.

Send your message to us

Carbon Additive Low Ash Low Sulphur Description

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches