Carbon Additve Low Ash Best Quality for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

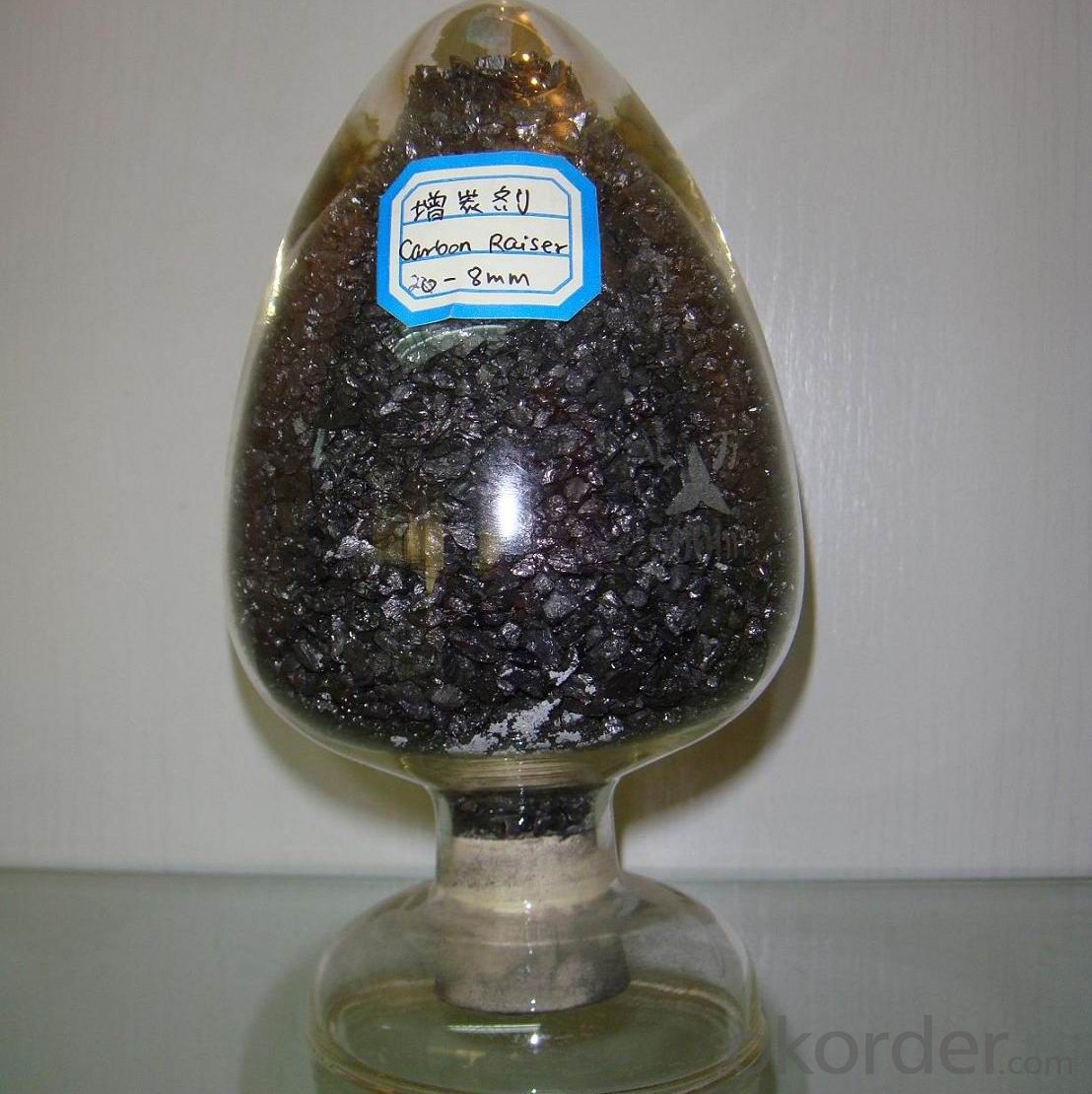

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

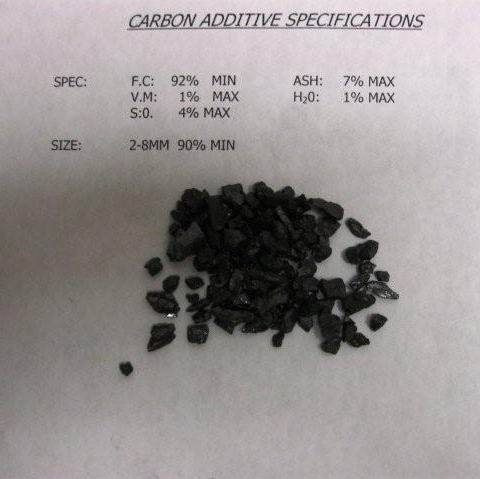

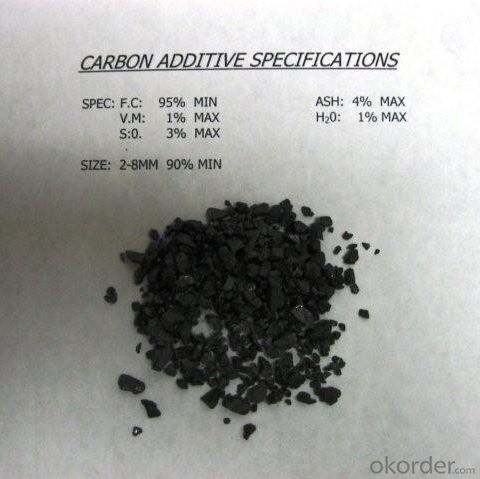

Specifications Carbon Additve Low Ash Best Quality Carbon Additve low Ash,S,P Structure Carbon Additve Low Ash Best Quality Shape: granule Dimensions: FC90-95% Product Type: Carbon Additive C Content (%): 90-95% MIN Working Temperature: - S Content (%): 0.5%MAX N Content (%): - H Content (%): 0.6%MAX Ash Content (%): 8.5%MAX Volatile: 2%MAX ADVANTAGE: low ash & sulfur COLOR: Black RAW MATERIAL: TaiXi anthracite Feature Carbon Additive Low Ash Best Quality Image Carbon Additive Low Ash Best Quality FAQ: Why we adopt carbon additive? Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation. Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking. Advantage: Carbon Additive Low Ash Best Quality 1.High quality and competitive price. 2.Timely delivery. 3.If any item you like. Please contact us. Your sincere inquiries are typically answered within 24 hours.

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost Specifications (%): Grade F.C Ash V.M Moisture S Size CR-95 ≥95 <4 <1 <1 <0.3 0-30mm

As buyer's request.CR-94 ≥94 <4 <1 <1 <0.3 CR-93 ≥93 <6 <1 <1 <0.4 CR-92 ≥92 <7 <1 <1 <0.4 CR-91 ≥91 <8 <1 <1 <0.4 CR-90 ≥90 <8.5 <1.5 <2 <0.4

- Q: Are carbon fibers organic polymer materials?

- No, carbon fiber is not an organic polymer material, and carbon fiber is an inorganic polymer materialOrganic polymer compounds referred to as polymer compound or polymer, also known as polymer is composed of one or several structural units repeatedly (103~105) compound repeat connected. Their elements are not many, mainly carbon, hydrogen, oxygen and nitrogen, but the molecular weight is large, generally above 10000, high millions.

- Q: How are carbon markets regulated?

- The integrity and transparency of emissions trading in carbon markets are ensured through a combination of international, national, and regional frameworks. The United Nations Framework Convention on Climate Change (UNFCCC) is a key international body responsible for overseeing carbon markets. It established both the Kyoto Protocol and the Paris Agreement. The Kyoto Protocol established an international emissions trading system that allows countries to trade emission allowances through the Clean Development Mechanism (CDM) and Joint Implementation (JI) projects. These projects are approved and monitored by the UNFCCC to ensure that emission reductions are genuine, measurable, and additional to what would have occurred without the projects. The Paris Agreement, which succeeded the Kyoto Protocol, introduced the Sustainable Development Mechanism (SDM), a new market mechanism. The SDM is designed to promote sustainable development and assist countries in achieving their climate goals by enabling emission reductions and removals through projects in developing countries. At the national and regional levels, governments and regulatory bodies play a vital role in carbon market regulation. They establish legal frameworks, set emission reduction targets, and develop domestic emissions trading systems. These systems involve the allocation of emission allowances to companies or sectors, monitoring and reporting of emissions, and the trading of allowances on regulated platforms. To maintain the integrity of carbon markets, stringent regulations are in place to prevent fraud, double-counting, and other forms of market manipulation. Independent verification and accreditation bodies are responsible for auditing emissions data and project methodologies to ensure compliance with established rules and standards. Additionally, market oversight and enforcement bodies are established to monitor and enforce compliance with regulations. These bodies have the authority to investigate and penalize non-compliance, including imposing fines or revoking emission allowances. In summary, the regulation of carbon markets encompasses a complex network of international agreements, national laws, and regulatory bodies. The objective is to establish a strong and transparent market that incentivizes emission reductions and supports the transition to a low-carbon economy.

- Q: How does carbon monoxide affect air quality and human health?

- Carbon monoxide (CO) is a colorless, odorless gas that can have detrimental effects on both air quality and human health. It is primarily released into the atmosphere through incomplete combustion of fossil fuels and biomass burning. In terms of air quality, high levels of carbon monoxide contribute to the formation of ground-level ozone and smog, which can impair visibility and cause respiratory issues. When it comes to human health, carbon monoxide is particularly concerning as it binds to hemoglobin in our red blood cells, preventing oxygen from being delivered to vital organs and tissues. This can lead to symptoms such as headaches, dizziness, confusion, and in severe cases, even death. Individuals with cardiovascular and respiratory conditions, as well as unborn babies and the elderly, are especially vulnerable to the harmful effects of carbon monoxide exposure. Therefore, proper ventilation and the use of carbon monoxide detectors are crucial to prevent its accumulation and protect both air quality and human health.

- Q: What are the different types of carbon-based polymers?

- There are several different types of carbon-based polymers, including polyethylene, polypropylene, polystyrene, polyvinyl chloride (PVC), and polyurethane.

- Q: What is the carbon content of different types of household waste?

- The carbon content of different types of household waste can vary significantly. Generally, organic waste such as food scraps, yard trimmings, and paper products have high carbon content, while non-organic waste like plastics and metals have low or no carbon content.

- Q: What are the consequences of increased carbon emissions on public health systems?

- Increased carbon emissions have significant consequences on public health systems. As carbon dioxide levels rise, so does the concentration of air pollutants such as particulate matter, ozone, and nitrogen dioxide. These pollutants have been linked to a range of respiratory and cardiovascular problems, including asthma, lung cancer, and heart disease. Additionally, climate change resulting from increased carbon emissions can contribute to the spread of infectious diseases, heat-related illnesses, and mental health issues. These impacts place a substantial burden on healthcare systems, leading to increased healthcare costs and strained resources.

- Q: What are the consequences of increased carbon emissions on human health?

- Human health is significantly affected by the increase in carbon emissions. One immediate consequence is the decline in air quality. Harmful air pollutants, like particulate matter, nitrogen oxides, and ground-level ozone, are formed due to carbon emissions. These pollutants can lead to respiratory problems, such as asthma, bronchitis, and other chronic obstructive pulmonary diseases. They can also worsen existing respiratory conditions, resulting in more hospitalizations and premature deaths. Moreover, carbon emissions contribute to climate change, which has extensive effects on human health. Rising temperatures can worsen the frequency and intensity of heatwaves, causing heat-related illnesses and deaths. Vulnerable populations, such as the elderly, children, and those with pre-existing health conditions, are particularly affected by heat stress. Climate change also influences the spread of infectious diseases. Changes in temperature and rainfall patterns can alter the behavior and distribution of disease-carrying vectors like mosquitoes and ticks. This can increase the transmission of vector-borne diseases, including malaria, dengue fever, and Lyme disease. Additionally, climate change can disrupt food and water supplies, leading to malnutrition and an elevated risk of waterborne diseases. Another consequence of carbon emissions is the increased occurrence of natural disasters, like hurricanes, floods, and wildfires. These events can cause physical injuries, displacement, and mental health issues, such as post-traumatic stress disorder. The destruction of healthcare infrastructure during disasters further hampers access to necessary medical care, aggravating health problems. It is important to note that vulnerable populations, such as low-income communities, indigenous communities, and developing countries, are disproportionately affected by the health impacts of increased carbon emissions. These groups often face limited access to healthcare, making them more susceptible to the consequences. In conclusion, the effects of increased carbon emissions on human health are severe. From the deterioration of air quality to the spread of infectious diseases and the occurrence of natural disasters, the impacts are extensive and pose significant risks to individuals and communities. It is crucial to mitigate carbon emissions and invest in sustainable practices to protect human health and establish a healthier and more sustainable future.

- Q: How does carbon affect the pH of rainwater?

- The pH of rainwater can be influenced by carbon, which occurs when carbon dioxide (CO2) in the atmosphere dissolves in rainwater. This process is known as the formation of carbonic acid (H2CO3). As a result of this reaction, the pH of rainwater decreases, making it more acidic. The carbonic acid breaks down into hydrogen ions (H+) and bicarbonate ions (HCO3-), which further contribute to the acidity of rainwater. Consequently, higher levels of carbon dioxide in the atmosphere, such as those caused by human activities like the combustion of fossil fuels, can result in an increase in the formation of carbonic acid and subsequently lower the pH of rainwater, leading to the occurrence of acid rain.

- Q: What are the properties of carbon nanotubes?

- Carbon nanotubes are cylindrical structures made entirely of carbon atoms. They have a unique set of properties that make them highly desirable in various fields of science and technology. Some of the key properties of carbon nanotubes include: 1. Exceptional strength and stiffness: Carbon nanotubes have an incredibly high strength-to-weight ratio, making them one of the strongest materials known to date. They are about 100 times stronger than steel but much lighter. This property makes them suitable for applications requiring lightweight but strong materials. 2. High electrical conductivity: Carbon nanotubes possess excellent electrical conductivity, allowing them to efficiently carry electrical current. They can be utilized as conductive components in various electronic devices, such as transistors, sensors, and energy storage systems. 3. Thermal conductivity: Carbon nanotubes exhibit high thermal conductivity, meaning they can efficiently conduct heat. This property makes them ideal for applications requiring efficient heat dissipation, such as thermal management in electronic devices. 4. Flexibility and resilience: Carbon nanotubes are highly flexible and can withstand significant deformation without breaking. They can be bent and twisted without losing their structural integrity, making them suitable for applications requiring flexibility, such as flexible electronics. 5. Unique optical and mechanical properties: Carbon nanotubes possess unique optical properties that vary depending on their structure and arrangement. They can absorb and emit light across a wide range of wavelengths, making them useful in applications like photodetectors and solar cells. Additionally, their mechanical properties, such as the ability to deform elastically, make them useful in applications requiring shock absorption and impact resistance. 6. Chemical stability: Carbon nanotubes are highly chemically stable, which means they can resist degradation or corrosion when exposed to various chemical environments. This property makes them suitable for applications in harsh conditions or as protective coatings. 7. Large aspect ratio: Carbon nanotubes have a high aspect ratio, with lengths often exceeding thousands of times their diameter. This characteristic allows them to form strong and lightweight composite materials when incorporated into a matrix, enhancing the overall strength and stiffness of the composite. Overall, the unique combination of properties exhibited by carbon nanotubes makes them an exciting and versatile material with immense potential for a wide range of applications, including electronics, aerospace, medicine, and energy storage.

- Q: How is carbon used in the production of textiles?

- Carbon is used in the production of textiles through various processes. For instance, carbon black, a form of carbon, is commonly used as a coloring agent in textile dyes, giving fabrics a wide range of colors. Additionally, carbon fiber, a lightweight and strong material derived from carbon, is used to create high-performance textiles for applications like aerospace, sports equipment, and automotive industries. Carbon-based chemicals are also used in textile manufacturing processes such as dyeing, finishing, and printing.

Send your message to us

Carbon Additve Low Ash Best Quality for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches