Carbon Additve Recarburizer for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

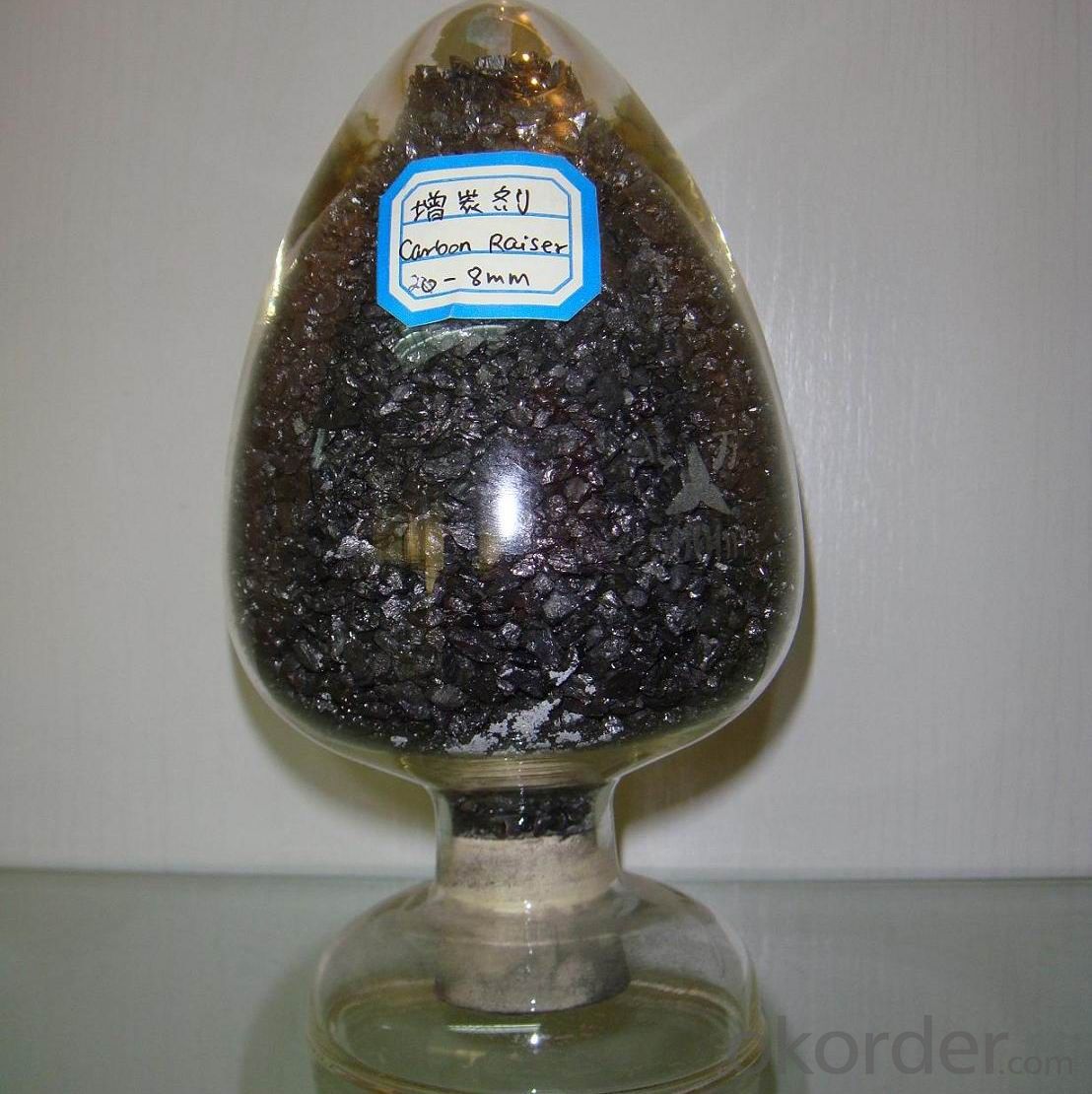

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

Specifications

Carbon Additve Recarburizer for Steelmaking

Carbon Additve low Ash,S,P

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

Structure

Carbon Additve Recarburizer for Steelmaking

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Feature

Carbon Additve Recarburizer for Steelmaking

Specifications (%): | ||||||

Grade | F.C | Ash | V.M | Moisture | S | Size |

CR-95 | ≥95 | <4 | <1 | <1 | <0.3 | 0-30mm |

CR-94 | ≥94 | <4 | <1 | <1 | <0.3 | |

CR-93 | ≥93 | <6 | <1 | <1 | <0.4 | |

CR-92 | ≥92 | <7 | <1 | <1 | <0.4 | |

CR-91 | ≥91 | <8 | <1 | <1 | <0.4 | |

CR-90 | ≥90 | <8.5 | <1.5 | <2 | <0.4 | |

Image

Carbon Additve Recarburizer for Steelmaking

FAQ:

Carbon Additve Recarburizer for Steelmaking

Why we adopt carbon additive?

Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation.

Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking.

Advantage:

Carbon Additve Recarburizer for Steelmaking

1.High quality and competitive price.

2.Timely delivery.

3.If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q: What is the role of carbonation in carbonated drinks?

- The purpose of carbonation in carbonated drinks is to give them their characteristic refreshing and bubbly sensation. Carbonation occurs when carbon dioxide gas is dissolved into a liquid, usually water, under pressure. This process produces carbonic acid, which adds a tangy taste to the drink. Carbonation serves multiple functions in carbonated beverages. Firstly, it enhances the flavor by creating a unique bubbly sensation that delights the taste buds and provides a refreshing feeling in the mouth. The effervescence resulting from carbonation also adds to the overall sensory experience, making the drink more enjoyable to consume. Additionally, carbonation acts as a natural preservative in carbonated drinks. The presence of carbon dioxide gas inhibits the growth of bacteria and other microorganisms, thus extending the shelf life of the beverage. This is especially important for soft drinks that are often stored for long periods before being consumed. Furthermore, carbonation plays a role in the presentation of carbonated drinks. The release of carbon dioxide gas creates bubbles and fizz, making the beverage visually appealing and enticing. This visual appeal is often associated with a sense of luxury and indulgence. In summary, carbonation is a vital element of carbonated drinks as it contributes to their taste, preservation, and visual appeal. It enhances the sensory experience and adds to the overall enjoyment of these beverages.

- Q: What are the advantages of carbon-based batteries?

- The advantages of carbon-based batteries include their relatively low cost, abundance of raw materials, and environmentally-friendly nature compared to other types of batteries. Additionally, they have a high energy density, allowing for longer battery life and greater power output.

- Q: How does carbon contribute to air pollution?

- Carbon contributes to air pollution primarily through the combustion of fossil fuels. When carbon-based fuels such as coal, oil, and natural gas are burned for energy, they release carbon dioxide (CO2) into the atmosphere, which is a greenhouse gas that contributes to global warming and climate change. Additionally, incomplete combustion of these fuels can produce other pollutants such as carbon monoxide (CO), volatile organic compounds (VOCs), and particulate matter, which all have detrimental effects on air quality and human health.

- Q: Who is the high carbon content of stainless steel and ordinary steel?

- This is not necessarily stainless steel is carbon steel, based on the addition of zinc, nickel and chromium and other elements

- Q: What kinds of carbon black paper do you have?

- Three, triad:And the triple carbon free carbon paper receipts can be divided into paper, medium paper and paper. The paper also called back coated paper (CB, Coated Back), the back of the paper coated with microcapsules containing force sensitive pigment oil; in the paper also called double coated paper (CFB, Coated Front and Back), the paper is coated with a chromogenic agent containing microcapsules coated on the back force sensitive pigment oil; the paper also called surface coated paper (CF, Coated Front), the paper only coated with chromogenic agent. Since the display paper (code SC, Self-Contained) is in the back of the paper coated with a layer of microcapsules containing force sensitive pigment oil, microcapsule coated positive chromogenic agent and pigment containing sensitive oil.Four, selection of carbonless paper:In the purchase and use of carbonless paper, preferably with the same company produced the same brand, paper collocation, production date and not apart for too long. Because the various manufacturers of products in brightness, color density, smoothness, thickness, stiffness, strength, color printing surface galling tone, compactness, ink and other indicators are different, so the different manufacturers of paper used in appearance, collocation, printability, collating, copying are affected.

- Q: How does carbon impact the formation of smog?

- Carbon plays a significant role in the formation of smog, particularly in the form of carbon monoxide (CO) and volatile organic compounds (VOCs). When fossil fuels are burned, such as in vehicle engines or power plants, they release carbon monoxide into the atmosphere. Carbon monoxide is a colorless and odorless gas that can react with other pollutants in the presence of sunlight to form ground-level ozone, a key component of smog. Furthermore, carbon-based compounds known as volatile organic compounds (VOCs) are also emitted from various sources, including industrial processes, gasoline vapors, and chemical solvents. These VOCs can undergo chemical reactions in the presence of nitrogen oxides and sunlight to create ground-level ozone as well. Both carbon monoxide and VOCs contribute to the formation of smog by reacting with nitrogen oxides (NOx) in the presence of sunlight. This chemical reaction forms ground-level ozone, which is a primary component of smog. Ozone is harmful to human health and the environment, and its formation is exacerbated by the presence of carbon emissions. Reducing carbon emissions is crucial to mitigating the formation of smog. Transitioning to cleaner and more sustainable sources of energy, such as renewable energy, can help decrease the amount of carbon released into the atmosphere. Additionally, implementing stricter emissions standards for vehicles and industrial processes can also contribute to reducing carbon emissions and consequently limit the formation of smog.

- Q: What do you mean by carbon fiber for 1K, 3K, 6K and 12K?

- This is the specification of carbon fiber, refers to the number of filaments in carbon fiber tow, 1K=1000 (root), 3K=3000 (root), 6K=6000 (root), 12K=12000 (root). At the same time, 1K, 3K, 6K, and 12K are also called small tow.The relationship between the properties of carbon fibers and the number of filaments is described below:According to the number of carbon fiber bundle of carbon fiber filaments can be divided into small tow and tow two. Compared with small tow, the disadvantage of large tow is that when the structure of the plate is made, the tow should not spread out, resulting in the increase of the monolayer thickness, which is not conducive to the structural design. In addition, large tow carbon fiber adhesion, wire breaking phenomenon more, which makes the strength and stiffness of the affected, a decrease in performance, the performance of dispersion will be larger. Aircraft, spacecraft generally only a small tow carbon fiber, so the small tow carbon fiber is also known as the "space" of carbon fiber, large tow carbon fiber is known as the "industrial grade carbon fiber.But large tow production costs than small tow low, and with the progress of the production technology, people familiar with the structure of the carbon fiber material, large tow carbon fiber more and more stringent requirements for reliability field. In this way, between the small and large tow tow distinguish changes, such as earlier in the number of single tow 12000 (12K) as the dividing line, but the number of carbon fiber 1K~24K is divided into small bundles, rather than 48K designated as large tow. While the Airbus Company has begun to use 24K carbon fibers in the manufacture of A380 super large aircraft, it is estimated that as the technology advances, the line between the small tow and the big tow will push up.

- Q: Carbon 60 related information

- The 60 is the solid carbon black, graphite and diamond. In addition, in recent years, scientists have discovered that some exist in new form of elemental carbon, which is more important in 1985 found C60. C60 is a molecule made up of 60 carbon atoms, similar to football. At present, people have made great progress in the research of C60, and the application of C60 in superconductor, material science and other fields is deepening. In our country, great achievements have been made in this field. For example, the metal doped C60 superconductor has been successfully developed in collaboration with the Physics Institute of Peking University and the Chinese Academy of sciences. It can be said that the discovery of C60 is of great importance to the study of carbon chemistry and even the whole field of chemistry.

- Q: How does carbon impact the availability of clean air?

- Carbon impacts the availability of clean air through its contribution to air pollution and climate change. When carbon-based fuels such as coal, oil, and natural gas are burned for energy production, they release carbon dioxide (CO2) into the atmosphere. CO2 is a greenhouse gas that traps heat in the Earth's atmosphere, causing the planet to warm up, leading to climate change. Climate change, in turn, affects air quality in several ways. Rising temperatures can increase the frequency and intensity of wildfires, which release large amounts of carbon dioxide and other pollutants into the air. Additionally, higher temperatures can exacerbate the formation of ground-level ozone, a harmful air pollutant that can trigger respiratory issues and other health problems. Furthermore, carbon emissions contribute to the formation of particulate matter, such as soot and fine particles, which can be harmful when inhaled. These particles can come from the burning of fossil fuels in vehicles, power plants, and industrial processes. Particulate matter can cause respiratory and cardiovascular problems and is especially harmful to vulnerable populations like children, the elderly, and those with pre-existing respiratory conditions. Reducing carbon emissions is crucial to improving air quality and ensuring the availability of clean air. Transitioning to renewable energy sources, improving energy efficiency, and implementing policies to reduce carbon emissions can all help mitigate the impact of carbon on air quality. Additionally, promoting sustainable transportation, reducing deforestation, and adopting cleaner industrial practices can contribute to cleaner air by reducing carbon emissions and other pollutants.

- Q: What is the boiling point of carbon?

- The boiling point of carbon is approximately 4,827 degrees Celsius (8,740 degrees Fahrenheit).

Send your message to us

Carbon Additve Recarburizer for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches