Butterfly Valves Ductile Iron Wafer Type DN500

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 80000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

1. Small in size and light in weight, easy instillation and maintenance. It can be mounted wherever needed

2. Simple and compact construction, quick 90 degrees on-off operation

3. Minimized operating torque, energy saving

4. Flow curve teeing to straight line, excellent regulation performance

5. Long service life, standing the test of tens of thousands opening/closing operations

6. Bubbles-tight sealing with no leakage under the pressure test

7. Wide selection of materials, applicable to various mediums

8.Simple and compact construction. Small in size and light in weight. Easy transportation, installation and maintenance.

9. Quick 90 degrees on-off operation. Minimized operating torque ,energy saving.

10. Excellent sealing performance with no leakage. Long service life.

11. Wide selection of materials ,applicable for various media..

12. Flow curve tending to straight line. Excellent regulation performance.

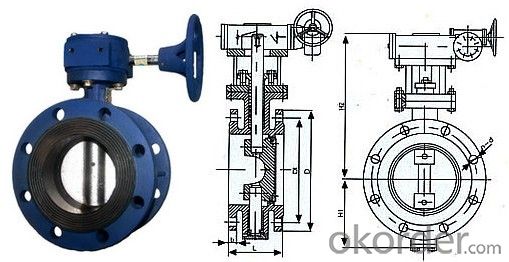

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: My caravan is a bit sluggish on the pick up, I replaced the wires/plugs and the electronic distributor(I think thats what it is..). still a bit sluggish. Should i look at the valve gasket? Or fuel filter, or fuel pump next? 03 caravan sport 3.3L

- There is no electronic distributor on your caravan it uses a coil pack To the 1st poster there is no valve pan gasket you have valve cover gaskets. The fuel filter on your van is Incorporated in the fuel pump module located inside your fuel tank. There a several things that can contribute to sluggish performance, look at your exhaust and make sure it is not bent/collapsed/restricting Dodge Chrysler Jeep Tech

- Q: The difference between butterfly valve d71x_10s and d341s-10

- Before distinguishing between the two, you must first read the identification of the valve type:D stands for butterfly valves,3 means that the worm gear is connected and the drive does not indicate the handle7 and 4 indicate pipe to clamp connection, pipe flange connection, respectively1 means single eccentric, that is, the stem is not in the center of the butterfly plateThe former S indicates the material name of the valve body - plastic, X means sealing and the lining material is rubberThe latter S indicates the sealing lining material code ---- plastic, and the valve body is cast iron.10 means stress.

- Q: How do you explain A in butterfly valve D37A1?

- Represents a seal or lining material symbol.Said sealing ring or lining material with the Chinese phonetic alphabet: B Babbitts D nitrided steel, acid resistant stainless steel H, J L Aluminum Alloy, hard rubber, nylon NL, P leather, SA PTFE, SC PVC, SD bakelite, T copper, TC enamel, X rubber, Y hard alloy

- Q: How much is the Honeywell butterfly DN300?

- Find the agent or find a reliable valve plant a lot of foreign brands are in Chinese OEM so find a reliable factory is relatively good service to keep up

- Q: For whatever reason, Mazda has made it next to impossible to change the PCV valve on the 929. I'm going to have to pull off the plenum and the passenger's side valve cover to replace a $2.00 PCV valve. Before I get too involved, I need to know the torque specs for the valve cover. Also, any other tips on this process would be greatly appreciated. Can I reuse the old valve cover gasket if it's still in good shape? Should I use any kind of sealant in addition to the gasket when I put it all back together? Thanks in advance, by looking at this motor, I can tell I'll have my work cut out for me (for a friggin $2.00 PCV valve, it's usually SO simple!). Like I said, any and all help is greatly appreciated.

- Mazda 929 Specs

- Q: Where are the exhaust valves, mud valves and butterfly valves?

- The exhaust valve is suitable for the pipeline with working medium, so as to improve the efficiency of the water conveyance equipment and protect the pipe from deformation and rupture. Sludge discharge valves are suitable for use in floating waste water treatment plants, such as gypsum. Slag, scale power stations, smelters, sugar mills.

- Q: CAD drawing of butterfly valve

- Your question is very international. Ha-haThis method of painting is not clear in one or two words.First you'll know the map, then you'll use CAD, so the two will add up.Guess you will.

- Q: Specifically an engine valve retainer.

- There okorder for year make model engine valve diagram and you should find a drawing of your setup.

- Q: What's the difference between butterfly valves and check valves?

- Butterfly valve is manual, only switch function.The check valve is an automatic valve, which prevents backflow of the pipe medium.

- Q: Butterfly valve is generally used in what position?

- It can also be used for switch control of low pressure pipeline medium.

Send your message to us

Butterfly Valves Ductile Iron Wafer Type DN500

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 80000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords