Butterfly Valve Universal ISO 5211 Mounting Pad. China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Standard or Nonstandard: Standard

Structure: Butterfly

Pressure: Low Pressure

Power: Manual

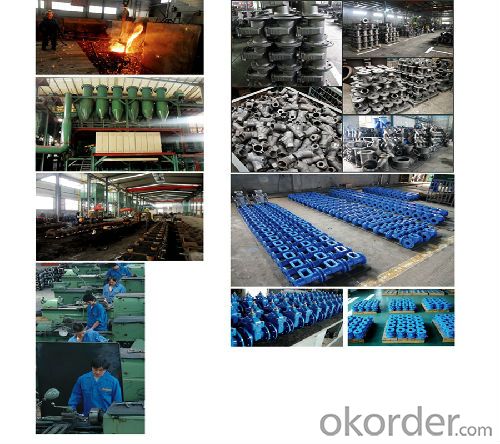

Material: Casting

Temperature of Media: Normal Temperature

Media: Water

Port Size: DN40-DN1200

Place of Origin: China (Mainland)

Wafer type: butterfly valve

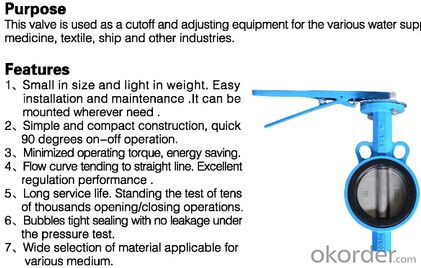

Butterfly features:

1. Small and light , and easy installation and mintanance. It can be mounted wherever needed.

2. Siple and compact construction, quick 90 degree on-off operation.

3. Miniminzed operating torque, energy saving.

4. Flow curve tending to straight line. Excellent regulation performance.

5. Long service life Standing the test of tens of thousands opening/closing operations.

6. Bubbles-tight sealing with no leakage under the pressure test.

7. Wide selection of materials, applicable forvarious medium.

Delivery Detail: Within 20 days

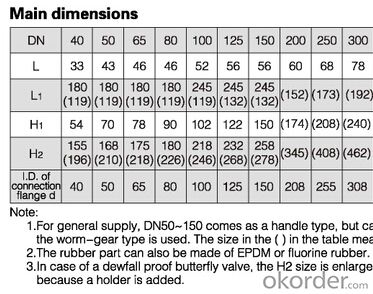

Specifications

Wafer type lined butterfly valve

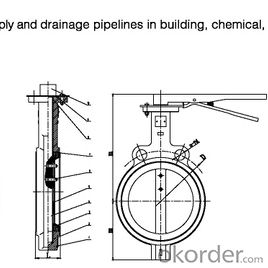

1.Design standard:ISO,BS,API

2.DN40-DN1200

3.PN10/PN16/PN25

4.Center lined disc

Wafer type lined butterfly valve

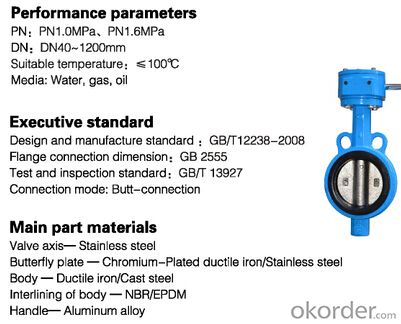

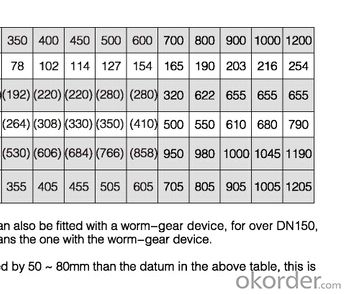

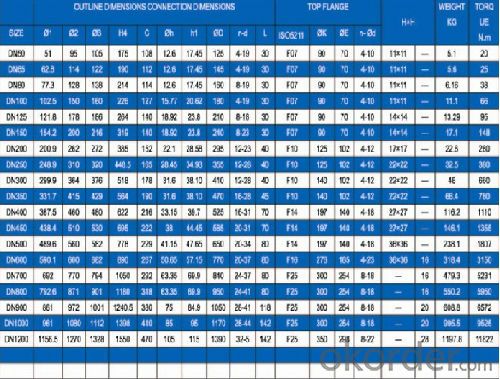

Technical Data

DN40-DN1200mm PN1.0-1.6MPa

General Design:ISO 5752 / BS 5155 / API 609

Body: Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel

Seat: EPDM, PTFE, NBR,Viton

Stem: Stainless Steel, Steel,

Disc: Ductile Iron with Nickel Coating,Ductile Iron with Nylon Coating, Stainless Stee 304/316l, Alu-Bronze,Duplex steel

Flange Connection:DIN,ANSI,JIS,BS

Product Features

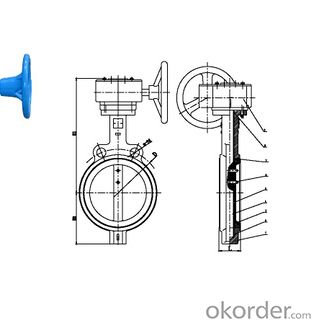

Wafer type flanged body style fit between FF or RF flanges

PTFE bushing ensure the maximum shaft support and centralized alignment

360°polished disc assures positive on-off

Hard-Backed Cartridge seat or Edge-Boot seat

The pin,spline or square connection are all available

Universal ISO 5211 mounting pad.

Brief of butterfly:

Butterfly valve can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

There are different kinds of butterfly valves, each adapted for different pressures and different usage. The zero offset butterfly valve, which uses the flexibility of rubber, has the lowest pressure rating. The high performance double offset butterfly valve, used in slightly higher-pressure systems, is offset from the cen tre line of the disc seat and body seal (offset one), and the centre line of the bore (offset two). This creates a cam action during operation to lift the seat out of the seal resulting in less friction than is created in the zero offset design and decreases its tendency to wear. The valve best suited for high-pressure systems is the triple offset butterfly valve. In this valve the disc seat contact axis is offset, which acts to virtually eliminate sliding contact between disc and seat. In the case of triple offset valves the seat is made of metal so that it can be machined such as to achieve a bubble tight shut-off when in contact with the disc.

Packaging Details: Plactic bag+Paper cover+Plywood cases

- Q: Does the wet alarm valve group need to install the signal butterfly valve?

- Wet alarm valve at the front of the signal butterfly valve with the main floor of the main role of the butterfly valve, first, maintenance, and two is the prompt sprinkler system, there is a signal butterfly valve closed, should be repaired as soon as possible.

- Q: Why use special flanges for butterfly valves?

- Mainly for clip type butterfly valve sealing ring on the valve body than the ordinary flange chip small diameter. Therefore, the ordinary flange can not guarantee the effective sealing effect. Therefore, you must use a dedicated butterfly flange sheet

- Q: The difference between butterfly valve d71x_10s and d341s-10

- Before distinguishing between the two, you must first read the identification of the valve type:D stands for butterfly valves,3 means that the worm gear is connected and the drive does not indicate the handle7 and 4 indicate pipe to clamp connection, pipe flange connection, respectively1 means single eccentric, that is, the stem is not in the center of the butterfly plateThe former S indicates the material name of the valve body - plastic, X means sealing and the lining material is rubberThe latter S indicates the sealing lining material code ---- plastic, and the valve body is cast iron.10 means stress.

- Q: What is the meaning of the D341*5-10 / 16ZB1 turbine butterfly valve flange said?

- D341 is flanged connection center plate butterfly valve under pressure 1.0MPa-1.6MPa ZB1 rubber soft seal

- Q: The water supply pipe is the gate valve And on the cross dry pipe are the gate valve? To answer the 30

- Crown valve pressThere is no standard answer to this question. I can only give you my personal opinionRiser butterfly valve is generally place in these places (the pump outlet valve, drainage system, upper and lower floors) riser are basically installed butterfly valve, butterfly valve is not cheap, fast speed is fast closing butterfly valve can be quickly closed and open educationYou see the water pipe installed valve (with all the cross tube is the basic gate) explanation, because in contrast to the quality and stability, the valve will be better, the site does not need fast switching, it will choose good stability point gateSum upThe drains are all butterfly valves, and the stabilizing pipes are all valves! (do not rule out a full use butterfly valve for stealing work)

- Q: How to calculate the size of the manual butterfly valve?

- [1] type code, transmission mode, connection form, structure form, sealing surface material or lining material, nominal pressure, valve body material, this is the most basic arrangement way now D341X-16C. [2]: butterfly valve also known as butterfly valve, control valve has a simple structure, can be used for low pressure pipeline valve switching control is closed parts (disc or disc) is a disk, around the valve axis to achieve the opening and closing a valve, the valve can be used to control the air water, steam, and all kinds of corrosive media, mud, oil, metals and radioactive liquid media and other types of fluid flow. On the pipeline, mainly from cutting and throttling. Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis of rotation, so as to achieve the purpose of opening or closing or regulation.

- Q: Should I connect the butterfly valve before and after the pump? Or gate valve?

- 1, valve, the fluid resistance is small, the sealing surface by the erosion of small and medium Chong brush. 2, opening and closing more effort. 3, medium flow unrestricted, no disturb, do not reduce pressure. 4. The shape is simple, the structure length is short, the manufacturing technology is good, and the scope of application is wide. Butterfly valve main deficiency is that it uses the pressure and temperature range is small. And poor sealing. Therefore, the gate valve should be preferred.Gate valve (gatevalve) is a gate valve used to open and close parts, and along the vertical axis of the valve seat movement, in order to achieve the opening and closing action of the valve. The valve can only be fully open and fully closed, opening and closing parts is the gate, the direction of motion perpendicular to the direction of the fluid, valve two square I-shaped sealing surface forming the wedge, the wedge angle varies with the valve parameters, usually 5 degrees is not high, medium temperature is 2 degrees 52'. Improve the process of valve, make up the sealing surface angle in the process of production deviation, this kind of gate is called flexible gate.

- Q: oil coming from valve into turbo charger

- it's located on pg 61222 of gm shop repair manual

- Q: What is the difference between the installation and function of a butterfly valve and butterfly valve?

- The principle of the valve gate valve is open and close cases, RAM direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed, can not be adjusted and the throttle. Gate has two sealing surface, the most commonly used mode gate valve of the two sealing surface forming wedge, wedge angle with valve parameters vary, usually 50, medium temperature is not high when 2 degrees 52. Wedge gate valve can be made into a whole, called the rigid gate; can also be made to produce micro deformation of ram, in order to improve its process of deviation, make up the sealing surface angle in the process, the gate is called the flexible gate. Valve closed, the sealing surface can only rely on medium pressure to seal, that is to rely on medium pressure to the gate sealing surface pressure to the other side of the seat to ensure the sealing surface seal, which is self sealing. Most of the valve is forced seal, that is, when the valve closes, to rely on external force to force the gate to the seat, in order to ensure the sealing surface sealing. Gate valve with the stem along with a straight line of motion, called the lift rod gate valve is also known as the bar gate valve. Usually there is a trapezoidal thread on the lifter. The rotating motion is changed into a straight line through the nut at the top of the valve and the guide groove on the valve body. That is to say, the operating torque is changed into the operating thrust. When opening the valve, when the gate lift height is equal to 1:1 times of the valve path, the passage of the fluid is completely unblocked, but at run time, this position is unable to monitor. In actual use, the top of the stem is used as a sign, i.e., the open position, as its fully open position.Temperature changes appear to consider locking phenomenon, usually open to the vertex position, and then rewind 1/2 1 circle, as a fully open valve position.

- Q: I have a good set of #142 Pontiac heads with small diameter valves. I want to have the heads enlarged to accept the larger Pontiac valves, and I have the larger exhaust valves out of #13 heads and the larger intakes from 6X8 heads. The valves appear ok and shiny on the stems

- Roll the valves by the stems on a perfectly flat table. If there is no wobble, your valves are most likely not bent. Take them to a machine shop and have them checked for imperfections and reground and they'll be good as new.

Send your message to us

Butterfly Valve Universal ISO 5211 Mounting Pad. China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords