A Grade Quality EPDM Waterproofing Membrane for Roof Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Specification for EPDM Waterproof Membrane:

There are two installation ways.one is full sticking,the other is hot welding.

Type | EPDM Waterproof Membrane | |||

Material | EPDM Rubber | |||

Thickness | 1.0mm | 1.2mm | 1.5mm | 2.0mm |

Size | 1.2m(width) * 20m(length)/roll | |||

Type | Vulcanized | |||

Pattern | Non-reinforced(homogeneous) | |||

Packing | 24sqm--80sqm/roll, with plastic bag | |||

Color | Black | |||

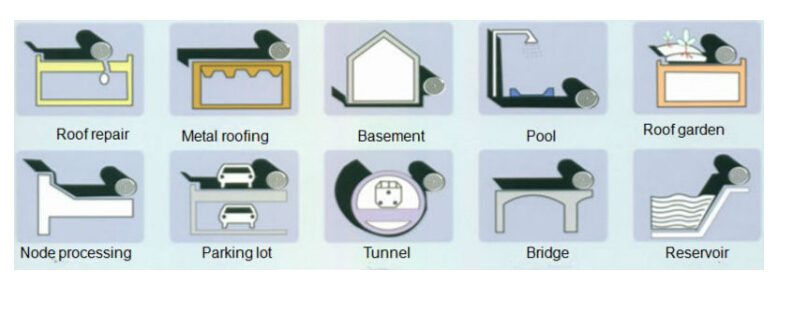

Application | Roofs, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | |||

2.Product Technicial Data for EPDM Waterproof Membrane:

No. | Item | Technical index | ||

JL1 | JF1 | |||

1 | Tensile strength at break Mpa | Normal temperature≥ | 7.5 | 4.0 |

60°C≥ | 2.3 | 0.8 | ||

2 | Elogation at break | Normal temperature≥ | 450 | 400 |

-20°C≥ | 200 | 200 | ||

3 | Tearing strength KN/m≥ | 25 | 18 | |

4 | Impermeability 30minutes No leak | 0.3Mpa | 0.3Mpa | |

5 | Low temperature flexibility °C≤ | -40 | -30 | |

6 | Heat air ageing 80°C x 168h | Tensile strength retention rate % ≥ | 80 | 90 |

Elogation retention rate % ≥ | 70 | 70 | ||

Apperance of 100% elogation | no crack | no crack | ||

3. Product Application:

a. Make sure the base surface smooth, clean and dry(Moisture<9%), then paint the delicated agent on the base surface. Start application till it is dry.

b. Reinforce the parts which are easy to leak, such as seam, hole, channel, wall, pipe and corner.

c. Application Method:

Lay the membrane directly. Be careful to control the overlaps of the long side and short side.

d. After application, a careful inspection is required. Make sure there is no air bubble, no fold, no falling away etc to guarantee the waterproof life.

4. Some photos:

- Q:Does a waterproofing membrane require a protective layer?

- Yes, a waterproofing membrane typically requires a protective layer. The protective layer helps to shield the membrane from various external factors, such as UV rays, weather conditions, mechanical damage, and chemical exposure, thereby enhancing its durability and longevity.

- Q:Is a waterproofing membrane resistant to chemicals?

- Yes, a waterproofing membrane is generally resistant to chemicals. Waterproofing membranes are designed to provide a protective barrier against water and moisture, and they are often made of materials that are chemically resistant. However, the level of chemical resistance may vary depending on the specific type of membrane and the type of chemicals it comes into contact with. It is important to consult the manufacturer's specifications and recommendations to ensure the membrane is suitable for the intended chemical exposure.

- Q:Can a waterproofing membrane be used on vinyl surfaces?

- Yes, a waterproofing membrane can be used on vinyl surfaces. The membrane serves as a protective layer that prevents water from penetrating and damaging the vinyl material.

- Q:Can a waterproofing membrane be used in roofs?

- Yes, a waterproofing membrane can be used in roofs. In fact, it is a commonly used method for protecting roofs from water damage. A waterproofing membrane is typically made of a durable material, such as rubber or modified bitumen, and is applied to the roof surface to create a barrier against water penetration. This membrane acts as a protective layer that prevents water from seeping into the underlying structure of the roof, thus preventing leaks and potential damage. Waterproofing membranes are especially useful for flat or low-sloped roofs, where water can easily accumulate and cause problems. Additionally, these membranes can be applied to various types of roofing materials, including concrete, metal, and asphalt, making them versatile and suitable for different roof types. Overall, using a waterproofing membrane in roofs is an effective way to enhance their durability and longevity, while also providing reliable protection against water infiltration.

- Q:Can a waterproofing membrane be used on balconies or decks?

- Yes, a waterproofing membrane can be used on balconies or decks. It helps to prevent water penetration and protect the underlying structure from moisture damage.

- Q:Does a waterproofing membrane require any special maintenance?

- Indeed, special maintenance is required for a waterproofing membrane. Despite its durability and ability to withstand various weather conditions, regular maintenance is necessary to uphold its effectiveness and longevity. Some maintenance tasks to be undertaken are as follows: 1. Conduct regular inspections: Examine the membrane for any signs of damage, such as cracks, tears, or punctures. Inspect the seams and edges to ensure they are adequately sealed. 2. Clean the surface: Eliminate any debris, dirt, or vegetation that might have accumulated on the membrane. This can be accomplished using a broom, brush, or pressure washer (if suggested by the manufacturer). 3. Clear drains and gutters: Verify that the drains and gutters connected to the membrane are free from clogs or obstructions. This will prevent water from pooling on the surface and causing potential harm. 4. Rectify any damages: Should any cracks, tears, or punctures be discovered, they should be repaired promptly to prevent water leakage. Adhere to the manufacturer's instructions for the appropriate repair method and materials. 5. Regularly inspect the entire waterproofing system: If the membrane is part of a larger waterproofing system, such as a basement or roof, it is essential to inspect and maintain the entire system. This may involve checking the integrity of other components, such as drainage pipes or flashing. 6. Consider professional maintenance: Depending on the size and complexity of the waterproofing system, engaging a professional maintenance service may prove advantageous. They can conduct thorough inspections, carry out necessary repairs, and offer expert guidance on maintaining the membrane. By adhering to these maintenance practices, one can ensure that their waterproofing membrane remains in optimum condition and effectively guards their structure against water damage.

- Q:Can a waterproofing membrane be used on concrete walls?

- Concrete walls can benefit from the use of a waterproofing membrane. These membranes are specifically designed to prevent water from penetrating the surface and can be applied to various surfaces, including concrete walls. Common materials used for these membranes include modified bitumen, rubberized asphalt, and synthetic polymers, all of which are highly resistant to water and moisture. By applying a waterproofing membrane to concrete walls, one can effectively prevent water seepage, dampness, and potential damage caused by water infiltration. The membrane acts as a protective barrier, stopping water from permeating through the concrete and reaching the interior spaces. Additionally, it helps maintain the structural integrity of the concrete by reducing the risks of cracks, efflorescence, and other forms of moisture-related deterioration. There are several types of waterproofing membranes available in the market, such as sheet membranes, liquid membranes, and cementitious coatings. The choice of the membrane depends on factors such as the specific application, the degree of water exposure, and the condition of the concrete wall. It is essential to select a membrane that is compatible with the concrete and provides long-lasting waterproofing protection. Before applying the membrane, it is crucial to properly prepare the concrete surface. This involves tasks such as cleaning, repairing any cracks or imperfections, and ensuring that the surface is dry and free from contaminants. The membrane is then installed according to the manufacturer's instructions, which usually involves adhering it to the concrete or applying a liquid membrane with a brush or roller. To sum up, a waterproofing membrane is a valuable solution for protecting concrete walls from water infiltration. By choosing the right type of membrane and following proper installation procedures, one can effectively preserve the durability and longevity of the concrete while safeguarding the interior spaces from potential water damage.

- Q:Are waterproofing membranes suitable for crawl spaces?

- Indeed, crawl spaces can be susceptible to moisture and water infiltration due to their positioning and inadequate ventilation. However, by implementing waterproofing membranes, one can effectively thwart water damage and issues arising from excessive moisture. These membranes are specifically engineered to establish a barricade against water and moisture, thereby preventing their intrusion into the crawl space and the subsequent development of problems like mold growth, decay, and structural deterioration. Moreover, the utilization of waterproofing membranes can contribute to enhancing the quality of indoor air by diminishing humidity levels in the crawl space. Consequently, it is strongly advised to employ waterproofing membranes in crawl spaces in order to guarantee a dry, sanitary, and healthful environment.

- Q:How does a waterproofing membrane handle temperature fluctuations?

- A waterproofing membrane is designed to withstand temperature changes through its flexibility and resistance to thermal expansion and contraction. Temperature fluctuations have the potential to cause cracks, leaks, and other damage to materials. However, a waterproofing membrane is typically made from durable and flexible materials like PVC or EPDM, which can endure these temperature changes without compromising their effectiveness. When faced with high temperatures, the membrane will slightly expand to accommodate the increased thermal energy. Conversely, when temperatures decrease, the membrane will contract to maintain its integrity. This flexibility allows the membrane to adapt to changing conditions without cracking or becoming brittle. Besides flexibility, a waterproofing membrane is also engineered to resist the sun's UV radiation. Over time, UV radiation can cause materials to deteriorate, resulting in decreased performance and possible leaks. By incorporating UV stabilizers into the membrane's composition, it can endure prolonged exposure to sunlight and maintain its durability even in harsh weather conditions. Furthermore, certain waterproofing membranes possess built-in insulation properties that regulate temperature fluctuations. These membranes provide additional thermal resistance, reducing heat loss in cold weather and minimizing heat gain in hot weather. This insulation layer stabilizes the temperature of the underlying structure, preventing damage caused by extreme temperature changes. Overall, a waterproofing membrane is designed to handle temperature fluctuations by being flexible, resistant to thermal expansion and contraction, and capable of withstanding UV radiation. These attributes guarantee that the membrane remains intact and effective in safeguarding the underlying structure from water damage, regardless of the surrounding temperature conditions.

- Q:Can a waterproofing membrane be used in conjunction with insulation materials?

- Yes, a waterproofing membrane can be used in conjunction with insulation materials. The membrane acts as a barrier to prevent water infiltration, while insulation materials provide thermal resistance to control heat flow. This combination is commonly used in construction to ensure both waterproofing and insulation performance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

A Grade Quality EPDM Waterproofing Membrane for Roof Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords