PVC roof waterproof membrane reputable supplier

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction

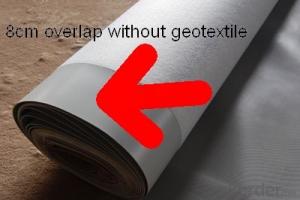

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane which is

made from polyvinyl chloride resin, and mixed with plasticizer, filler, antioxygen, ultraviolet

absorber and other auxiliaries.

2. Specification

1) Size: 2.05(width)*20m (length)

2) Thickness: 1.2mm; 1.5mm; 2.0mm

3) Type: Homogeneous, Reinforced, With fabric back

4) Exposed and Non-exposed

5) Color: white, Grey or customized

6) Certificate: ISO9001/14001

3. Applications

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

4. Features

1) Excellent aging resistance.

2) Root resistant penetration, specially used on planting roof.

3) Welding installation. Joints are solid and environment friendly, no pollution.

4) High tensile strength, good elongation and dimensional stability.

5) Good plasticity, easy and suitable for details installation.

6) Fireproof. Fire extinguished out of the ignition resource.

7) Surface is smooth, no fading and dirty resistant.

- Q:Does a waterproofing membrane require a protective layer?

- A protective layer is necessary for a waterproofing membrane. It has various functions. Firstly, it prevents damage to the membrane during and after installation by acting as a barrier against sharp objects, construction debris, and potential punctures. Additionally, the protective layer distributes loads evenly and provides stability to the membrane, reducing the risk of damage from foot traffic or heavy equipment. Moreover, the protective layer acts as a shield against UV rays, which can degrade the membrane over time and cause reduced effectiveness and potential leaks. It also helps regulate temperature fluctuations that can stress the membrane and compromise its waterproofing capabilities. To summarize, a protective layer is crucial for the durability and performance of a waterproofing membrane. It safeguards against physical damage, UV radiation, and temperature fluctuations, ensuring the membrane effectively keeps water out and maintains the integrity of the protected structure.

- Q:Can a waterproofing membrane be used for a fountain?

- Yes, a waterproofing membrane can be used for a fountain. Waterproofing membranes are designed to create a protective barrier against water, making them suitable for fountains to prevent leakage and maintain the structural integrity of the fountain.

- Q:Can a waterproofing membrane be used in balconies or decks?

- Yes, a waterproofing membrane can be used in balconies or decks. Waterproofing membranes are specifically designed to prevent water penetration and protect underlying structures from moisture damage. Balconies and decks are often exposed to the elements, including rain and snow, which can lead to water damage and deterioration. By installing a waterproofing membrane, it creates a barrier that prevents water from seeping into the underlying structure, ensuring its longevity and durability. Additionally, waterproofing membranes can also protect against other forms of water damage, such as mold and mildew growth, which can be detrimental to the integrity of the balcony or deck. Overall, using a waterproofing membrane in balconies or decks is an effective solution to maintain their functionality and extend their lifespan.

- Q:Can a waterproofing membrane be used in conjunction with green building practices?

- Yes, a waterproofing membrane can definitely be used in conjunction with green building practices. In fact, incorporating a waterproofing membrane into the construction of a green building can help enhance its overall sustainability and efficiency. One of the key principles of green building practices is to maximize energy efficiency and reduce the environmental impact of a building. By installing a waterproofing membrane, the building's envelope can be protected from moisture intrusion, preventing water damage and potential mold growth. This, in turn, helps maintain the structural integrity of the building, reducing the need for repairs and replacements, which can be resource-intensive and generate waste. Additionally, a waterproofing membrane can contribute to better indoor air quality. By preventing water infiltration, it helps create a dry and healthy living or working environment, minimizing the risk of respiratory issues and other health problems associated with dampness. Furthermore, a waterproofing membrane can improve the energy efficiency of a building. By preventing water from seeping into the walls or foundation, it reduces the potential for heat loss through moisture evaporation, thus reducing the energy needed for heating and cooling. This can lead to reduced energy consumption and lower carbon emissions, aligning with the goals of green building practices. It is important, however, to choose a waterproofing membrane that is environmentally friendly and meets green building standards. Look for membranes that are made from recycled or sustainable materials and have low VOC (volatile organic compound) content. Additionally, consider selecting a membrane that is designed for durability and longevity, as this can further reduce the environmental impact by minimizing the need for replacement over time. In conclusion, a waterproofing membrane can be a valuable addition to any green building project. It helps protect the building envelope, improves indoor air quality, and enhances energy efficiency. By selecting an environmentally friendly membrane, the overall sustainability of the building can be further improved.

- Q:Can a waterproofing membrane be used on aerated concrete block surfaces?

- Yes, a waterproofing membrane can be used on aerated concrete block surfaces. Aerated concrete blocks are known for their porous nature, which can make them prone to water penetration. Applying a waterproofing membrane on the surface of the blocks can help prevent water from seeping through and causing damage. The membrane forms a barrier that keeps water out while still allowing the blocks to breathe and release any trapped moisture. This helps to maintain the integrity and longevity of the aerated concrete block structures. However, it is important to ensure that the waterproofing membrane is specifically designed for use on aerated concrete blocks, as different materials require different types of membrane for optimal performance.

- Q:Can a waterproofing membrane be used in areas with high groundwater levels?

- Certainly, it is possible to utilize a waterproofing membrane in regions with elevated groundwater levels. In truth, it is strongly advised to employ a waterproofing membrane in such areas to safeguard the integrity of the edifice from water penetration. The primary purpose of a waterproofing membrane is to construct a barrier that hinders the ingress of water into the building or structure. This becomes particularly crucial in zones with high groundwater levels due to the substantial pressure exerted by the water, which heightens the chances of water damage or flooding. By implementing a waterproofing membrane, you can effectively minimize the risk of water infiltration and ensure the long-lasting resilience of the structure.

- Q:Does a waterproofing membrane require a primer before application?

- Yes, a waterproofing membrane typically requires a primer before application. A primer helps to enhance the adhesion of the membrane to the substrate and ensures a proper bond between the two. It also helps to seal the surface, preventing any moisture or contaminants from compromising the effectiveness of the waterproofing system. Using a primer before applying the waterproofing membrane is important for achieving a durable and long-lasting waterproofing solution.

- Q:Can a waterproofing membrane be used on precast iron surfaces?

- Precast iron surfaces can benefit from the application of a waterproofing membrane, which serves as a protective layer against water infiltration. This membrane, consisting of a thin material, effectively blocks the entry of water or moisture into the surface. Its versatility allows it to be utilized on various surfaces, including precast iron. By acting as a barrier, the waterproofing membrane effectively safeguards the precast iron from detrimental effects like rust or corrosion that could arise from water exposure. This becomes particularly vital in settings where the precast iron surface is constantly exposed to water or humidity, such as outdoor installations or high humidity areas. Incorporating a waterproofing membrane on precast iron surfaces aids in prolonging the structure's lifespan and preserving its structural integrity.

- Q:Can a waterproofing membrane be used for a planter box?

- Indeed, a planter box can benefit from the use of a waterproofing membrane. The primary function of a waterproofing membrane is to impede the intrusion of water into the surface it is applied to. Consequently, it is a suitable choice for safeguarding the planter box against moisture-induced harm. By employing a waterproofing membrane on the interior of the planter box, a barrier is established that thwarts the infiltration of water and the potential harm it may inflict upon the wood or material of the planter box. This can prove particularly advantageous when the planter box is persistently exposed to water, such as in outdoor settings or for hydroponic gardening endeavors. In essence, the utilization of a waterproofing membrane for a planter box can contribute to its longevity and ensure its sustained good condition.

- Q:Can a waterproofing membrane be used in areas with high foot traffic or heavy loads?

- A waterproofing membrane is viable for use in areas subjected to heavy foot traffic or substantial loads. These membranes are created to serve as a protective barrier against water infiltration and can withstand different forms of stress, including foot traffic and heavy loads. However, it is imperative to select a waterproofing membrane that is explicitly designed for such circumstances. Multiple membrane options are available, each possessing varying levels of durability and strength. It is of utmost importance to seek guidance from a professional waterproofing expert or manufacturer to ensure that the chosen membrane is suitable for the specific requirements of the high foot traffic or heavy load area. Proper installation and maintenance of the membrane are also crucial for its long-term effectiveness in these conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC roof waterproof membrane reputable supplier

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords