E Glass Stitched Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 12000 kg

- Supply Capability:

- 240000kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

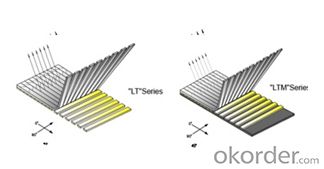

Two layers of roving(550g/㎡-1250g/㎡) are aligned at 0°/90° with or without a layer of chopped strands(0g/㎡-500g/㎡.

2.Product Structure

3.Product Specifications

Product No. | Overall Density | .0° Roving Density | .90° Roving Density | Chop Density | Polyester Yarn Density |

(g/m2) | (g/m2) | (g/m2) | (g/m2) | (g/m2) | |

E-LTMC1603 | 671.74 | 303.8 | 247.96 | 101.62 | 18.36 |

E-LTMC1608 | 844.76 | 303.8 | 247.96 | 274.64 | 18.36 |

E-LTMC1808 | 903.8 | 303.8 | 307 | 274.64 | 18.36 |

E-LTMC1810 | 934.31 | 303.8 | 307 | 305.15 | 18.36 |

E-LTMC1815 | 1086.89 | 303.8 | 307 | 457.73 | 18.36 |

E-LTMC2408 | 1101.04 | 405.66 | 401.46 | 274.64 | 19.28 |

E-LTMC2415 | 1284.13 | 405.66 | 401.46 | 457.73 | 19.28 |

E-UDL450 | 479.14 | 405.66 | 55.12 | - | 18.36 |

E-UDL500 | 490.85 | 405.66 | 66.83 | - | 18.36 |

E-UDL600 | 608.9 | 566.92 | 23.62 | - | 18.36 |

E-UDL1200 | 1207.34 | 1133.86 | 55.12 | - | 18.36 |

Special specification can be produce according to customer requirements.

4.FAQ

a.Packaging:

Each roll is wound onto a paper tube which has an inside diameter of 76mm and the roll has a diameter of 275mm. The roll is wrapped up with plastic film,and then packed in a cardboard box or wrapped up with kraft paper. The rolls can be horizontally placed. For transportation, the rolls can be loaded into a cantainer directly or on pallets.

b.Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q:Can fiberglass mat tissue be used in automotive applications?

- Automotive applications can indeed make use of fiberglass mat tissue. This lightweight fabric, comprised of fine glass fibers, is frequently employed in the automotive industry for a range of purposes. These include reinforcing composite materials, enhancing mechanical properties, and decreasing weight. When it comes to automotive applications, fiberglass mat tissue is often utilized in the manufacture of fiberglass-reinforced plastics (FRP) components. These components encompass body panels, interior trim parts, engine covers, and various structural elements. By incorporating fiberglass mat tissue as a reinforcement layer during the production process, the strength, stiffness, and impact resistance of these components can be improved. Moreover, fiberglass mat tissue plays a vital role in reducing the weight of automotive parts while maintaining their structural integrity. This is of particular significance within the automotive industry, as reducing the weight of vehicles can result in heightened fuel efficiency and reduced emissions. In addition, fiberglass mat tissue boasts exceptional corrosion resistance, rendering it suitable for automotive applications that involve exposure to moisture, chemicals, and harsh environmental conditions. All in all, fiberglass mat tissue is a versatile material that can be effectively employed in a myriad of automotive applications. Its usage can enhance performance, reduce weight, and improve durability.

- Q:Can fiberglass mat tissue be used for reinforcement in composites?

- Fiberglass mat tissue, composed of glass fibers randomly arranged, can reinforce composites. It is frequently utilized in the manufacturing of composites to enhance their strength. By combining the mat tissue with resin, a sturdy and durable composite material can be created. The random orientation of the fibers contributes to the composite structure's strength and reinforcement in multiple directions. Moreover, the mat tissue's flexibility allows for easy layering and molding into intricate shapes, making it suitable for a range of applications in industries like automotive, aerospace, construction, and marine. In conclusion, fiberglass mat tissue is extensively employed and highly effective as a reinforcement material in composites.

- Q:Can fiberglass mat tissue be used for repairing fiberglass truck beds?

- Yes, fiberglass mat tissue can be used for repairing fiberglass truck beds. It is commonly used in such repairs due to its strength, durability, and ability to bond well with the existing fiberglass surface.

- Q:Is fiberglass mat tissue resistant to corrosion?

- Yes, fiberglass mat tissue is resistant to corrosion. Fiberglass is made of non-metallic substances, such as glass fibers, that do not rust or corrode like metals do. This makes fiberglass mat tissue an ideal material for applications where corrosion resistance is required, such as in the construction industry for reinforcing concrete structures or in the marine industry for boat building. Additionally, fiberglass mat tissue is also resistant to chemicals, moisture, UV rays, and extreme temperatures, further enhancing its durability and longevity.

- Q:What is the tensile strength of fiberglass mat tissue?

- The tensile strength of fiberglass mat tissue typically ranges between 30 and 150 pounds per inch (lb/in). However, it is important to note that the exact tensile strength can vary depending on the specific type and quality of fiberglass mat tissue being used.

- Q:Is fiberglass mat tissue resistant to fading?

- In general, fiberglass mat tissue tends to lack resistance against fading. Fading refers to the loss of original color or brightness in a material caused by exposure to sunlight or other environmental factors. Although fiberglass itself is known for its durability and ability to withstand weathering, the mat tissue used in fiberglass products often succumbs to fading over time. This can be attributed to both the binder or resin used to bind the fiberglass fibers together and the pigments or dyes used to color the tissue. When exposed to UV rays and other outdoor elements, these components can deteriorate and fade, resulting in a decrease in color intensity or brightness. Therefore, if maintaining the visual appeal of a fiberglass product is important, it may be necessary to take additional protective measures, such as applying a UV-resistant coating or using pigments specifically formulated for outdoor use.

- Q:Is fiberglass mat tissue suitable for automotive applications?

- Yes, fiberglass mat tissue is suitable for automotive applications. Fiberglass mat tissue is a versatile material that offers numerous benefits when used in automotive applications. It provides excellent strength and durability, which is essential for automotive parts that need to withstand harsh conditions and heavy usage. Fiberglass mat tissue also has good thermal and electrical insulation properties, making it suitable for applications where temperature resistance and electrical insulation are required. Additionally, fiberglass mat tissue is lightweight, which can help improve fuel efficiency and overall vehicle performance. It is also easy to mold and shape, allowing manufacturers to create complex automotive parts with precision. Furthermore, fiberglass mat tissue is resistant to corrosion, chemicals, and UV radiation, ensuring the longevity and reliability of automotive components. Overall, the unique properties of fiberglass mat tissue make it an ideal choice for various automotive applications, including but not limited to body panels, interior components, structural reinforcements, and sound insulation. Its strength, durability, insulation properties, lightweight nature, and resistance to corrosion and chemicals make it a reliable and cost-effective material for the automotive industry.

- Q:Can fiberglass mat tissue be used for electrical insulation?

- Yes, fiberglass mat tissue can be used for electrical insulation. Fiberglass mat tissue is a non-woven fabric made from fine glass fibers, and it has excellent electrical insulation properties. It is capable of withstanding high temperatures and has a high dielectric strength, making it suitable for various electrical applications. It is commonly used as an insulation material in electrical transformers, motors, generators, and other electrical equipment. The fiberglass mat tissue provides a barrier that prevents the flow of electrical current and protects the components from electrical shocks or short circuits. Additionally, it is also resistant to moisture, chemicals, and UV radiation, further enhancing its suitability for electrical insulation.

- Q:How does the width of fiberglass mat tissue affect its conformability?

- The width of fiberglass mat tissue can have a significant impact on its conformability. Generally, a wider width of fiberglass mat tissue allows for greater flexibility and adaptability to different surfaces and shapes. This is because a wider mat tissue can cover larger areas, allowing for smoother transitions and better conformability to irregular surfaces. On the other hand, a narrower width of fiberglass mat tissue may be more rigid and less able to conform to complex shapes or contours. It might struggle to properly adhere to uneven surfaces, resulting in potential gaps or imperfections. Additionally, a narrower width may limit the flexibility and maneuverability of the mat tissue during installation or application. Therefore, the width of fiberglass mat tissue is an important factor to consider when determining its conformability. A wider width generally offers better conformability and the ability to cover larger areas, while a narrower width may have limitations in adapting to complex surfaces.

- Q:What is the maximum temperature resistance of fiberglass mat tissue?

- The maximum temperature resistance of fiberglass mat tissue can vary depending on the specific product and its intended use. However, in general, fiberglass mat tissue is known for its excellent thermal resistance properties. It can typically withstand temperatures ranging from 400 to 600 degrees Fahrenheit (200 to 315 degrees Celsius) without undergoing significant structural or performance degradation. This makes it suitable for a wide range of high-temperature applications, including insulation, fireproofing, and thermal insulation in industries such as automotive, aerospace, construction, and manufacturing. It is important to note that the exact maximum temperature resistance may vary based on factors such as the thickness, composition, and specific manufacturing processes of the fiberglass mat tissue. It is always recommended to consult the manufacturer's specifications and guidelines to ensure the appropriate usage and performance of the product in high-temperature environments.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

E Glass Stitched Combo Mat

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 12000 kg

- Supply Capability:

- 240000kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords