PPR type A1 hot melt copper core ball valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 carton

- Supply Capability:

- 100000 carton/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Quick Details

Material: Plastic

Technics: Injection

Type: Valve

Place of Origin: Zhejiang, China (Mainland)

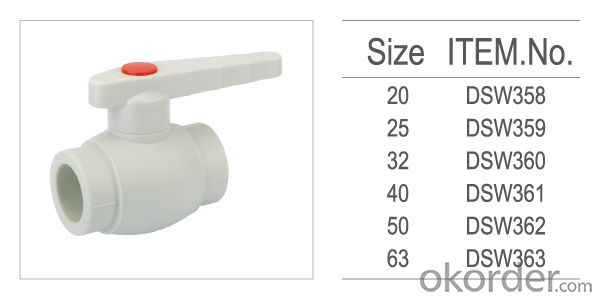

Model Number: DSW358-363

Connection: Welding

Shape: Equal

Head Code: Round

Standard: ISO,DIN,EN,MSS,API,BS,ANSI

Certification: ISO9001,CE

Specifications

Standard: DIN8077/8078

Material: R200P from Korea

Packaging & Delivery

Packaging Details:

1. Large carton:515x400x220 Cubage:0.04532 M3

Small carton:390x255x250 Cubage:0.0248 M3

2. PE poly bag+ cartonDelivery Detail: 15 days/ 20" container; 25 days/ 40HQ

Our Advantages:

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

Applications

> Distribution for cool and hot water;

> Duct for drinkable water system;

> Pipes for kinds of high-temperature and low-temperature heating system;

> Pipes for heating and coolling settings in solar energy system;

> Connecting pipe for air conditioners.

FAQ

Q1:How can i get a sample?

A1: You can get samples by communicate with our export sales.

Q2:How long is delivery?

A2:Delivery time will be 30-45 days according to order quantity.

- Q:Are plastic tubes resistant to mold and mildew?

- Yes, plastic tubes are generally resistant to mold and mildew.

- Q:Can plastic tubes be used for plumbing applications?

- Yes, plastic tubes can be used for plumbing applications. Many types of plastic, such as PVC (polyvinyl chloride) and PEX (cross-linked polyethylene), are commonly used in plumbing due to their durability, flexibility, and resistance to corrosion. These plastic tubes are often used for water supply lines, drainage systems, and even underground piping.

- Q:I have my own Bath Body company and want to add foot care to my line. Well I have the ingredients and know how to make the foot care, but I have yet to be able to find EMPTY, plastic tubes I can fill to be able to sell my product. Any ideas on a supplier? I'm done many searches in many serach engines with no luck! :-(

- I found this site that might sell the supplies you are looking for. Just search for pump in the upper right hand corner of the site.

- Q:I was changing my engine oil via the dipstick tube and a special suction device that pumps the old oil out of the sump to be replaced with fresh oil. Unfortunately, i had to patch up a hole in the tube on the suction device with parcel tape/sellotape wrapped around and a small piece of tape (around 2x2 square) fell into the engine dipstick tube and appears to have slid down into the oil sump.Will the oil filter make any difference in keeping melted plastic out of the engine? Am i best calling up the manufacturer, not the dealer as i don't want them to know about my error. The engine still runs and i have driven 20 miles so far with no problems. 2009 year Citroen C1Thanks

- This is worrisome. As the others say, the worst scenario is the tape gets against the pickup screen and suddenly causes loss of oil pressure. If that happens you will immediately get a low oil pressure warning light but that's something you don't want to happen anyway. However since the piece of tape is 2 x 2 or thereabouts at this point it is almost certainly still rolled up and stuck at the bottom of the dipstick tube. There would not be room for it to easily escape and fall into the sump… yet. There should be one or two screws at the bottom of the dipstick tube to secure it to the engine. If you remove those screws and pull the dipstick tube out, with the dipstick unit, you should find the tape at or near the bottom of the tube. Remove the tape, throw it away, put the tube back in, and sin no more.

- Q:Why, in general, the strong tube is plastic tubes, weak tubes are metal tubes?

- Weak metal pipe is mainly anti-interference, shielding role. Strong PVC is because the cost material cost and construction low construction speed, simple process, smooth inner wall wear line resistance is small but low strength, in more than 40 pipes generally required chroma metal tube or galvanized metal tube special.

- Q:i was wondering what would cause oil to lightly spray out of the plastic tube that hangs down out of the top end of the piston. the tube comes out of the top end right before the exhaust header bolts onto the piston.

- The link doesn't work - session is timed out. Always give year, make, engine size and model # when asking questions. We need all of that info to give an informed answer. I know what tube you are talking about. That tube is the breather hose for the power valve. As the piston rings start to ware, the oil in the premix doesn't get fully burned and accumulates on the power valve and lt's linkage. The engine is probably overdue for a top end rebuild and power valve cleaning. Remove the cover to see how much crud is in there. 2 stroke engines require rebuilds quite often, to prevent damage to the cylinder. If the top end is fresh, remove and clean the power valve. Otherwise clean the valve and replace the piston rings.

- Q:So I was wondering how much some plastic tubes (decent size) would cost if I wanted to get it from a dollar store, I'm thinking they're around $3 but I'm not sure. I just need to know so I can think of the colours I can get before I go get some paints. Thanks.

- Well, if you can find them at the dollar store, I will go out on a limb and suggest that they might cost....a dollar.

- Q:how can i undo the super glue? plzz help. 10 points for best way that works.

- lightly heated with a lighter,but not enough to burn the plastic

- Q:How do plastic tubes compare in cost to other packaging options?

- Plastic tubes are generally considered a cost-effective packaging option compared to other alternatives.

- Q:Where is the orifice tube located in a 2000 Pontiac Grand Prix3.8 liter V-6

- Recover the refrigerant. Refer to Refrigerant Recovery and Recharging . Remove the engine air cleaner. Refer to Air Cleaner Assembly Replacement in Engine Controls--3.1L or Air Cleaner Assembly Replacement in Engine Controls--3.8L. Remove the vacuum brake booster. Refer to Power Vacuum Brake Booster Replacement in Hydraulic Brakes. Remove the condenser tube. Refer to Condenser Tube Replacement . Remove the expansion (orifice) tube: 5.1. Use needle-nose pliers in order to grip the orifice tube. 5.2. Use a turning motion along with a push-pull motion in order to loosen the impacted orifice tube. 5.3. Remove the orifice tube. Important: DO NOT use any solvents or chemicals to clean the expansion (orifice) tube porous plastic inlet filter. Inspect the expansion (orifice) tube for the following conditions and clean or replace with a new tube as indicated: ? Broken plastic frame (1) ; replace tube. ? Inlet filter (3) damaged or plugged with fine gritty material; replace tube. ? Inlet filter (3) coated with metal chips, flakes, or slivers; coating may be removed with low pressure shop air ONLY and reused if cleaned satisfactorily. ? If reusing the tube, discard the O-ring seals (2). Installation Procedure

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PPR type A1 hot melt copper core ball valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 carton

- Supply Capability:

- 100000 carton/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords