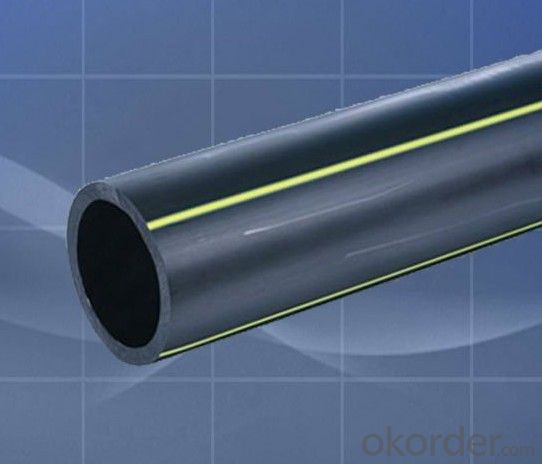

HDPE Gas Pipe - Plastic Tubes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of HDPE Gas Pipe :

Place of Origin | China (Mainland) |

Material | HDPE |

Specification | dn20~dn630 |

Length | 4m,5.8m,11.8m |

Thickness | Standard |

Standard | ISO4427, ISO4437 |

Raw Material | PE80, PE100 |

Color | Black, Blue |

Temperature | -40℃~60℃ |

| | |

Product Description of HDPE Gas Pipe:

Material: PE80/ PE100 (mainly PE 100 now).

Sizes: 20mm--630mm

SDR: SDR11, SDR13.6, SDR17, SDR21, SDR26, SDR33

Pressure: 0.4Mpa(PN4), 0.6Mpa(PN6), 0.8Mpa(PN8), 1.0Mpa(PN10), 1.25Mpa(PN12.5), 1.6Mpa(PN16)

Color: Black or others on request

Connection: Socket-fusion jointed, butt-fusion jointed , electron-fusion jointed, flange jointed

Standard: ISO4427, ISO4437, GB/T 13663-2000

Certification: ISO9001, ISO14001

Application: Water supply, Industries liquids transportation , sewage conduit

Identifies: black water pipe identifies the color at least three blue stripes, and evenly distributed along the pipe circumference

Advantage of HDPE Gas Pipe:

1. Non-toxic, no heavy metal additives, no fouling, not breed bacterium,

2. Corrosion resistant: PE is inert material and it can resist the corrosion of many chemical mediums, or electron chemical corrosion. except for few strong oxidants

3. High strength, good performance to resist the environmental stress cracking, good creep resistance.

4. Good flexibility: small diameters, PE pipe for water supply can be coiled and supplied for longer length, which saves a large number of fittings, PE pipe can be easily shifted according to requirement of the projects.

5. Light weight, simple safe and reliable welding technique, convenient construction and lower cost of the whole engineering,

6. Smooth interior wall, small water resistance, high flow capacity,

7. Long service life, up to 50 years under normal conditions.

8. Recyclable, benefit to the environment

- Q: he, of course used a new needle, but all he did was changed the needle and the plastic tube, and was on to the next person. Is this considered 'santitary'? I need professional answers PLEASE. Thanks.

- I use disposables too but wipe down my machine and clean every other area including my work area, clip cords, foot switch cord, power supply, etc. Anything I touch I clean thoroughly between clients. Although the machine itself doesn't touch blood, the hands that touch the machine do. The machine often requires minor adjustments during the tattoo process which means the hands that are in contact with contaminates touch the machine; ergo.. ntamination. Basically, I'd look elsewhere if the person is in that much of a hurry they can't adequately disinfect their workspace.

- Q: What is the level of transparency of colored plastic tubes?

- The level of transparency of colored plastic tubes can vary depending on the specific color and thickness of the tube. However, in general, colored plastic tubes tend to be less transparent than clear plastic tubes, as the color pigments can obstruct some of the light passing through.

- Q: How do plastic tubes compare to metal tubes?

- Plastic tubes are generally more lightweight, flexible, and resistant to corrosion compared to metal tubes. However, metal tubes are often stronger and more durable, making them suitable for high-pressure applications and extreme temperatures. The choice between plastic and metal tubes depends on the specific requirements and intended use.

- Q: Are plastic tubes prone to cracking or breaking?

- Yes, plastic tubes are prone to cracking or breaking, especially when subjected to excessive pressure, extreme temperatures, or if they are made from low-quality materials.

- Q: Please help me!!! This is for my science class and i am so confused xS

- A magnet gets attracted to metal (copper) Which means in a tube it will be attracted from all the directions This attraction holds the magnet in its current position But the the gravity attracts it down, while the tube holds it And resultantly the magnet tries to obey both the attraction (it tries to stay still and move down) which makes it fall slower than its fall in plastic tube where the plastic tube offers no attraction

- Q: Why should the residential outdoor drainage pipe be preferential for underground drainage plastic pipes? What's the harm of using precast concrete pipes?

- The buried plastic drain pipe has many excellent performances compared with the precast concrete pipe. The plastic pipe has the advantages of light weight, large length, less joint, convenient laying, reliable sealing, no leakage, and less pollution to the underground water source. In addition, the utility model has the advantages of high impact resistance, corrosion resistance, acid and alkali resistance, long service life, etc..

- Q: Do plastic tubes have any UV resistance?

- Yes, plastic tubes can have varying degrees of UV resistance depending on the type of plastic used. Some plastics, such as PVC and acrylic, are naturally UV resistant, while others may require the addition of UV stabilizers to enhance their resistance to UV radiation.

- Q: Hot melt construction technology of PPI plastic pipe

- When welding elbow or three way, according to the design drawing requirements, should pay attention to the direction, in the pipe fittings and pipe in the straight direction, with auxiliary sign mark its position;

- Q: im making a light bulb vaporizer and on the top im sticking a plastic tube into a cork and i wanted to know if the vapor from the weed is hot enough to melt the plastic in the tube, and obviously plastic fumes are toxic so i wanted to know if thats safe. if not, is rubber tubing any safer? or would the vapor melt that too? dont tell me not to smoke, i get it how its bad for you

- It's a great source for more information about the many benefits of portable herbal vaporizers.

- Q: Are plastic tubes resistant to bending or flexing?

- Yes, plastic tubes are generally resistant to bending or flexing due to their rigid nature.

Send your message to us

HDPE Gas Pipe - Plastic Tubes

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords