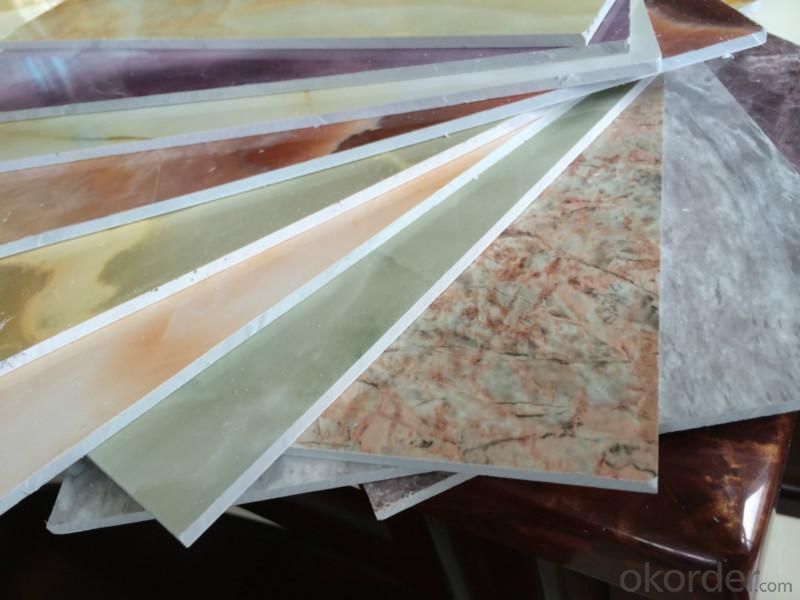

Good surface brightness water proof pvc plastic sheet pvc sheet pvc sheet roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 150000 m²/month

- Option:

- "1220mm × 2440mm; 1560mm × 3050mm; 2050mm × 3050mm ; or as your request ."

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

Our PVC Foam Board/Sheet Size:

Width: 1250mm-2050mm, 2050mm in max

Length: Any length

Standard size:1220*2440mm, 1560*3050mm, 2050*3050mm

NOTE: we can make other size according customer requirment

| Payment | L/C,T/T,Western Union, MoneyGram, Paypal |

| MOQ | 50PCS |

| Delivery | 2. Material Introduction:

3. Application:

|

PVC Foam Board Type

pvc celuka foam board, white pvc foam board,black pvc foam board,colored pvc foam board,red pvc foam board,yellow pvc foam board,green pvc foam board,blue pvc foam board and so on.our pvc foam sheet other name is pvc foam board, pvc foam panel, pvc foam plate,rigid pvc foam board,pvc free foam sheet ,pvc plastic foam sheet,pvc forex sheet,pvc crust foam sheet,pvc extruded foam sheet,hard foam pvc sheet,pvc celuka foam sheet,pvc cabinet foam sheet and so on.

- Q:It looks like a plastic, but I know there is a specific name for it.And maybe if you know the name, what big brand stores sell them?thank you soooo much for any help!

- Photo gels, and none. They're a specialty item

- Q:What are the different surface treatments available for plastic sheets?

- There are several surface treatments available for plastic sheets, including: 1. Coating: Plastic sheets can be coated with various materials like acrylic or polyurethane to enhance their appearance, provide added protection against scratches, and improve chemical resistance. 2. Laminating: Lamination involves applying a thin layer of plastic film onto the surface of the sheet, which can provide additional strength, durability, and resistance to moisture, UV radiation, and chemicals. 3. Printing: Plastic sheets can be printed with designs, logos, or patterns using techniques like screen printing, digital printing, or offset printing, allowing for customization and branding opportunities. 4. Embossing: This treatment creates a textured or raised pattern on the surface of the plastic sheet, adding a tactile dimension and aesthetic appeal. 5. Etching: Etching involves chemically or mechanically altering the surface of the plastic sheet to create a matte or frosted appearance, reducing glare and improving light diffusion. 6. Varnishing: Applying a clear varnish to plastic sheets can provide a glossy finish, enhancing the visual appeal and protecting the surface from scratches and abrasion. These surface treatments offer a range of benefits, allowing plastic sheets to meet specific functional and aesthetic requirements in various industries such as automotive, packaging, construction, and signage.

- Q:For this project I'm working on (Its a robot head I'm making from an old football helmet), and I need to use something for the eye screen piece (Sorta like the eye scanner thingy on the cylon helmets). Something black tinted,see-through (Without every thing being blurry), and most importantly bendable.Do you know where I can find such a thing?

- Plexiglass Menards

- Q:My house is 50 years old and is lacking in insulation in the garage ceiling. Above the garage are bedrooms. Currently there is 3 of fiberglass with an aluminum vapor barrier within a 2x10 joist. I'd like to put R-30 fiberglass in the cavities but the 25' rolls of insulation are unfaced and the faced R-30 rolls are only in 48 batts. 4' sections are easier to put up but that is not a concern of mine.

- Yea you can do that .Get a good stapler to ad hear the plastic to the wood. No stapler , Use Tacks. or even nails..

- Q:Can plastic sheets be used for insulation against electricity?

- Yes, plastic sheets can be used as an insulator against electricity. Plastic is a non-conductive material that does not easily allow the flow of electricity, making it an effective choice for insulation purposes.

- Q:Pink fiberglass insulation comes either faced or unfaced. On DIY shows on TV, I almost always see people using unfaced insulation and putting a sheet of plastic visqueen over the studs, rather than using faced insulation and not needing visqueen. Which method is better?

- Visqueen Plastic

- Q:Hi guys, I'm about to tile my bathtub surround and have some questions regarding moisture barriers. I already have the 1/2 durock cement board and 6 mil plastic sheeting. Before I put up the plastic sheeting on the studs, I wanted to double check to see what people thought was a better moisture barrier... Redgard painted directly onto the cement board or the 6 mil heavy duty plastic sheeting attached to the studs. If you pick one over the other, can you tell me why? Is there a difference in how well each one will protect from long term moisture problems? It would be nice to hear the pros/cons to Redgard vs the plastic sheeting.I'm debating whether or not I should just go buy some Redgard and leave my plastic sheeting for another purpose. But if they both offer the same long term protection, then I'm happy just sticking with my plastic sheeting since it will save me a trip to the store and I am more familiar with that as a moisture barrier.

- I've done a whole lot of this work over the years. Redgard is the best product I've ever seen for a moister barrier It's the standard for shower / tub surrounds. It's easy to use and will protect for a lifetime. Hang your cement board with the proper screws. Tape the seems and corners with fiberglass tape. Paint the redgard over the entire surface. Let dry; you know it's dry because it will turn from pink to red in color. Add another coat (or two) over the seems and corners to make sure the seems are sealed. Let dry. Install your tile or stone using thin set mixed with polymers. When you grout make sure to mix your grout with polymers. I know some guys who will use thin set to mud the seems before taping. This works well if you have some bigger gaps, but redgard is pretty thick stuff, like pudding. This type of installation will insure no water gets back behind your walls and will last a lifetime. Plastic has the issue of nail / screw holes, trapping water, and condensation. Redgard dose not because it is a moister barrier that you can lay tile directly on. There are other options and systems, but they tend to be more costly and harder to install. On a side note: I find redgard dose not apply well with a roller. It's very thick. I like to use a large brush. Plus a brush helps insure a good thick coat.

- Q:Can plastic sheets be used for vacuum packaging?

- Yes, plastic sheets can be effectively used for vacuum packaging. They are commonly utilized in the food industry to seal products, preventing oxygen exposure and maintaining freshness. Plastic sheets create an airtight barrier, enabling the removal of air and creating a vacuum-sealed environment.

- Q:What is the difference between PVC plastic gusset plate and aluminium alloy gusset plate?

- PVC plastic buckle: PVC as raw materials, processed into the groove type profile, has the characteristics of light weight, easy installation, waterproof, moisture-proof, anti moth, its surface color pattern change very much, and resistant to pollution, easy cleaning, sound insulation, heat insulation performance is good, especially in the process of adding new flame retardant materials, which can be from the fire that destroyed, use more safety. It is low cost and good decorative effect, so it occupies an important position in the family decoration ceiling materials, and becomes the leading material for the ceiling of toilets, kitchens, balconies and so on. Suspended ceiling is a kind of technique often used in interior design. People's vision often contact with it more time, so the shape of ceiling and artistic treatment have obvious influence on space effect.

- Q:i want to melt some of my unused cd's to make a uniform plastic sheet. but i haven't succed, i tryed putting them in the stove but it was a total mess...any idea? i'm trying to reach the point of melting when the plastic is like liquid, to work with it easyer. thanks

- it probably wouldnt work with anything you would have at home a kiln would burn it a double boiler wouldnt get it hot enough recycling companies granulate it and melt it in a chamber then extrude it but i dont think that would work for you also when plastic melts it is kindof syrupy the best thing for you to do is to go out and buy a sheet of plastic

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Good surface brightness water proof pvc plastic sheet pvc sheet pvc sheet roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 150000 m²/month

- Option:

- "1220mm × 2440mm; 1560mm × 3050mm; 2050mm × 3050mm ; or as your request ."

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords