High Temperature Resistance PVC Foam Board Plastic Sheets

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

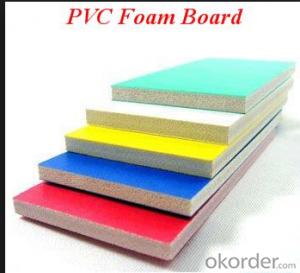

There are 2 kinds of PVC foam board, one is Common PVC foam board with white surface, the other is called Exclusive PVC foam board with colorful surface.

The PVC foam board is made through foaming and pressing into shape with additive. It is widely used in Sanitaryware, Construction material and Advertising material.

PVC foam board has its characteristics of easily sawed, bonded, nailed, joint and hot moulding.

We are specialized in manufacturing PVC foam board.

Standard Size We Provide

-1220*2440mm,Thickness:1mm-25mm

-1560*3050mm,Thickness:1mm-20mm

-2050*3050mm,Thickness:1mm-18mm

Features:

1. Waterproofing.

2. Fire retardant and self-extinguishing.

3. Heat preservation.

4. Sound-insulated.

5. Insulation.

6. Non-corrosion.

7. Non-toxic.

8. Tough,rigid with the high impact strength.

9. Stable color retention.

10. Dampproof.

11. Anti-deformed

Applications:

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection

4. Sanitarywares, kitchen cabinet, washroom cabinet.

Good performance:

1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

7, nail, wrest and rivet

Please tell me the following information and I'll send you the quotation without delay:

1.Color(white,black,grey,red,blue or other)

2.Thickness(1.0mm-33mm)

3.Size(Customized is available)

4.Density(0.35-0.90/m3)

5.Quantity(affecting the delivery time)

- Q: I must be an idiot. I bought GBC's SelfSeal Laminating Sheets (9x12) and need to laminate both sides of a 8.5x11 piece of paper. The instructions say to lay the paper face down on the non adhesive side and then peel away the liner and seal. What am I supposed to seal it with? Another laminating sheet? When I pull the liner away the adhesive side is facing away from the page and sticks to everything. Any help would be appreciated.Thanks

- Self Seal Laminating Sheets

- Q: Can plastic sheets be used for window glazing?

- Yes, plastic sheets can be used for window glazing.

- Q: What is the average cost of plastic sheets?

- The average cost of plastic sheets depends on various factors such as the type of plastic, size, thickness, and quality. It can range from a few dollars for small, thin sheets to hundreds of dollars for larger, thicker sheets.

- Q: OK, I have to do some landscaping and I want to try to prevent weeds from popping up, so I planted 10 Lantana and around the whole area I laid a clear plastic drop cloth, I cut about 12 inch holes for each of the lantana and I covered the whole thing with mulch. I want to make sure that this will not kill the lantana, the plastic does not let water or air through however like I said I cut 12 inch openings for the plants, is this adequate?

- if you live in a really warm climate, you might kill everything underneath the plastic. The ground will heat up and the plastic will trap the warmth and the soil won't breathe. Let's hope it doesn't kill your plants.

- Q: My doxie puppy is 7mo and chews on everything under the sun. While at work today the got the lid of a candle and a dryer sheet. usually unsupervised everything is put up or away to avoid these things happening but I have no Idea where she got it from but either way. she chewed the plastic around the lid off and I found most of them but I think she swallowed a few. Six hours later the threw up clear liquid and it had a two very small spots of blood and I mean so small almost specks. She is still eating drinking and humping my arm so I asume she is ok for the moment but I was just wondering if I should be overtly worried. thank you!

- Hi Since you mentioned the small spots of blood, you should first do a good examination of her mouth to see if she has a small cut. I would otherwise just monitor for now. It's possible that a sharp edge can cause an injury in the digestive tract. If it becomes worse or she develops other symptoms, you should contact your Vet for their recommendations. You might consider getting her a Deer Antler to curb her chewing on everything. It will likely become her favorite toy to chew on, and they Last for a long time. Best of Luck!

- Q: We are doing a classroom simulation and want to build a space shuttle out of PVC pipe and connectors, and black and white plastic sheeting. The students sit inside at the controls. I have seen mockups made from 2 liter pop bottles but this is not that. I saw one at the science teachers convention in San Diego in 2002 but cannot seem to find the directions on how to build my own.

- Your students could probably come up with some great ideas, no matter their age. They will learn more if they design the shuttle. Start them out in groups of 2 or 3 and have them brainstorm ideas (give them the rules for brainstorming). They then select the best ideas and make some simple sketches of how it can work. Them have them bring practice material from home to make a scale prototype. Use the best prototype to create your full size shuttle. Yes - I know this takes more time but they will be developing critical thinking and problem solving skills. Each additional project becomes easier for them as they build their skills. As the teacher you become the facilitator - guiding them through the project. Number1 rule for you is to NEVER NEVER answer their questions. Make them actually think. Ask them, what do you think, where could you look to find the answer, have you tried to ......

- Q: How to flatten a bent plastic sheet?

- If it's too big, it can't be pressed several times. It can only be cut off at the bottom of the U type, and then heated with a sickle. Then the two pieces of the PC board are held together with a small piece of plastic. All of our plastic buckets are made of this method. But be careful with the soup when you're working. I hope I can help you.

- Q: Can plastic sheets be used for machine covers?

- Yes, plastic sheets can be used for machine covers as they provide a protective barrier against dust, moisture, and other contaminants, helping to preserve the integrity and functionality of the machines.

- Q: What are the kinds of plastic sheets?

- PP board can be used in addition to the above products, but also used in the washing machine backplane, refrigerators, insulation layer, frozen food, drugs, rum and other packaging. Hollow board production line can also be used to produce PE hollow board to supply insulation partition for urban construction and rural area.

- Q: Iam doing a project with painters sheeting plastic which needs to be bond together without unlocking.I do not know which quick drying glue to use.Can anyone tell me which glue is the right glue for my project? (preferably quick drying glue ) Thanks,and HAPPY HOLIDAY.....HO,HO,HO,HO,HO.

- contact cement. apply glue to both surfaces and let dry (about 2 minutes) then press together. I would suggest you try a sample section to make sure the chemicals in the glue won't damage the materials.

Send your message to us

High Temperature Resistance PVC Foam Board Plastic Sheets

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords