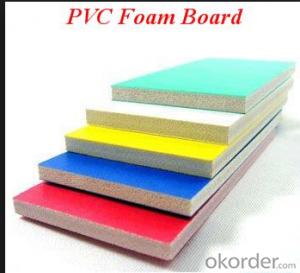

Plastic Sheets - PVC Foam Board Sheets in Different Colors and Sizes for Industrial Applications

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

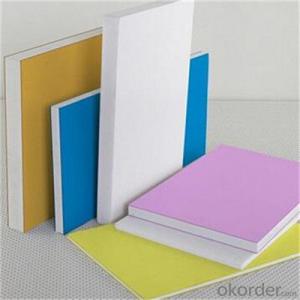

There are 2 kinds of PVC foam board, one is Common PVC foam board with white surface, the other is called Exclusive PVC foam board with colorful surface.

The PVC foam board is made through foaming and pressing into shape with additive. It is widely used in Sanitaryware, Construction material and Advertising material.

PVC foam board has its characteristics of easily sawed, bonded, nailed, joint and hot moulding.

We are specialized in manufacturing PVC foam board.

Standard Size We Provide

-1220*2440mm,Thickness:1mm-25mm

-1560*3050mm,Thickness:1mm-20mm

-2050*3050mm,Thickness:1mm-18mm

Features:

1. Waterproofing.

2. Fire retardant and self-extinguishing.

3. Heat preservation.

4. Sound-insulated.

5. Insulation.

6. Non-corrosion.

7. Non-toxic.

8. Tough,rigid with the high impact strength.

9. Stable color retention.

10. Dampproof.

11. Anti-deformed

Applications:

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection

4. Sanitarywares, kitchen cabinet, washroom cabinet.

Good performance:

1, plastic coating, membrance-stuck and printing

2, with the usual equipment and tools, it can be processed again.

3, welding and bonding

4, cutting and sawing

5, bending when heated-up, thermal forming

6, hole-drilling, Channeling and die cutting

7, nail, wrest and rivet

Please tell me the following information and I'll send you the quotation without delay:

1.Color(white,black,grey,red,blue or other)

2.Thickness(1.0mm-33mm)

3.Size(Customized is available)

4.Density(0.35-0.90/m3)

5.Quantity(affecting the delivery time)

- Q: Kitchen roof plastic buckle how to dismantle?

- Considering the safety of the roof should be in the kitchen ceiling is disassembled, especially the removal of ceiling in use for more than 20 years in the kitchen, because the original structure has started aging, plus the original ceiling decoration decoration requirements due to a lot of big hole, so that the local bearing capacity decline.

- Q: Can plastic sheets be used for vacuum forming in the aerospace industry?

- Yes, plastic sheets can be used for vacuum forming in the aerospace industry. Vacuum forming is a widely used manufacturing process in aerospace for creating lightweight and complex shapes. Plastic sheets, such as thermoplastics, are heated and then molded over a pattern or mold using vacuum pressure. These formed plastic parts can be used for various applications in the aerospace industry, including interior components, aircraft panels, and even some structural parts.

- Q: the unit is built in the wall. window covers dont fit.air leask from the main vent.the maintenacne guy told me to cut cardboard strips and stick it outside (exterior ) of the building its on a high flooralso cold air leaking from the filter above the kitchen cooking range..please help asap

- Not much to do with the AC except cover it tightly on the inside with a plastic sheet secured tightly. Covering the outside could be dangerous due to height and what if someone turns it on while that outside cover is on, you could damage the unit. Thats just the nature of those things, they are a big hole in your wall. The vent hood should have a damper that is forced open by the flow of air when the blower is on. Take off that filter and see if you can see such a thing and see if it is working properly. If you block this device off, use a non flamable material such as foil etc.

- Q: What is the PP board, PE board?

- Polypropylene and polyethylene are non-toxic plastic, with lighter and high toughness, therefore used as substitute for wood chopping board. But don't change over the years, with a long time have board should pay attention to the debris produced, eat or not good.

- Q: Are plastic sheets resistant to bending under heavy loads?

- Yes, plastic sheets are generally resistant to bending under heavy loads due to their inherent flexibility and strength. However, the degree of resistance may vary depending on the specific type and thickness of the plastic sheet used.

- Q: Are plastic sheets suitable for electrical insulation?

- Yes, plastic sheets are suitable for electrical insulation. Plastic materials such as PVC, polyethylene, and polypropylene have excellent electrical insulating properties and are commonly used for insulation purposes in electrical systems. They offer high dielectric strength, good resistance to moisture and chemicals, and are non-conductive, making them an effective choice for protecting and insulating electrical components.

- Q: Lets say person A buys 2 tabs of acid, puts it in a plastic baggy, and inserts in pocket. Is there any chance of the lsd bleeding through the plastic and being absorbed into person A's leg?

- No, there is far too little LSD to be absorbed. Plus plastic barrier will act as a barrier.

- Q: Can plastic sheets be recycled into new sheets?

- Yes, plastic sheets can be recycled into new sheets through a process known as plastic sheet recycling.

- Q: Are plastic sheets resistant to cracking from heavy loads?

- Yes, plastic sheets are generally resistant to cracking from heavy loads due to their high tensile strength and flexibility. However, the extent of resistance may vary depending on the specific type and quality of plastic used.

- Q: Can plastic sheets be used for hygienic applications?

- Yes, plastic sheets can be used for hygienic applications. They are commonly used in various industries such as healthcare, food processing, and cleanrooms to provide a barrier against contaminants, facilitate easy cleaning, and maintain hygienic conditions. Plastic sheets can be easily sanitized, resistant to moisture, and offer protection against bacteria and other pathogens, making them suitable for hygienic applications.

Send your message to us

Plastic Sheets - PVC Foam Board Sheets in Different Colors and Sizes for Industrial Applications

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords