10 Year Guarantee Anti-Flame Acrylic Plastic Sheets in Many Colors

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3000KG kg

- Supply Capability:

- 3000,000 KG Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

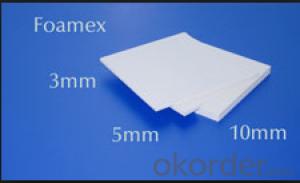

Specification Of 10 Year Guarantee Anti-Flame Acrylic Sheet With Many Colors

1 Size:

Thickness: 5.0--20.0mm Tolerance:±0.2mm

Width: 200--2100mm Tolerance:±1.0mm

Length: within 10m Tolerance:±1.0mm

Normal Size:1250mm×1850mm,1250mm×2480mm

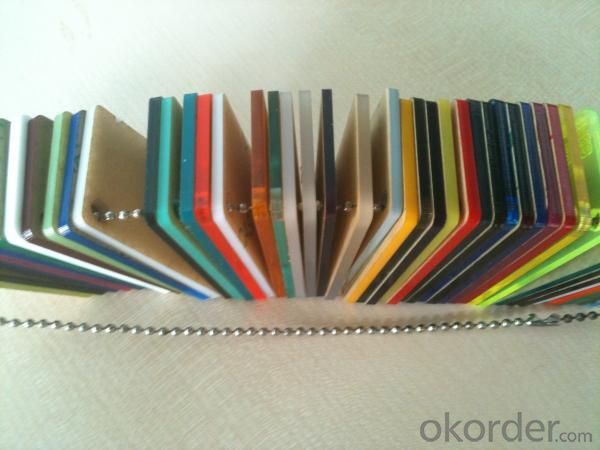

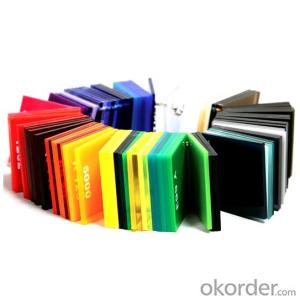

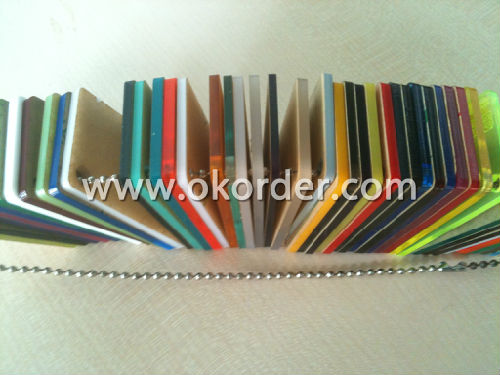

2 Color: all colors are available

3 High quality and good price

Features Of 10 Year Guarantee Anti-Flame Acrylic Sheet With Many Colors

1 Perfect transparency and the light transmittance with 93%.

2 Excellent electrical insulation , very light in weight.

3Strong surface hardness and good weather resisting property

4 Beautiful in colour, easy to clean

Applications Of 10 Year Guarantee Anti-Flame Acrylic Sheet With Many Colors

1 Construction: show window, doors, light-absorpting shade, telephone booth.

2 Advertisement: lamphouse, signboard,indicator,display rack.

3 Vehicle: door and window of car and train.

4 Medical: infant incubator, many kinds of medical apparatus.

Pictures Of 10 Year Guarantee Anti-Flame Acrylic Sheet With Many Colors

- Q: What are the requirements for plastic channel plate routing?

- The spacing between the slots shall be less than 0.5m, and the starting point and terminal shall be fixed at the ends of 0.3m. The cross section of the groove plate wiring should be less than 6mm2, and the same circuit board can only be installed with the same circuit wire. The inner conductor of the groove plate shall not be connected with the wire joint in the junction box, and the slot plate wiring shall not be arranged in the wall and ceiling.

- Q: I want to form plastic sheet using heat. Will this work? Plug a rheostat into the wall. Plug a cord into the rheostat. Cut the end of the cord and attach the bare ends to a piece of sheetmetal. Will this heat the metal w/o it being a shock hazard?

- 1. Yes, there is a shock hazard. 2. Your circuit may burn up the power cord before tripping the breaker but the sheet metal will not get warm.

- Q: Can plastic sheets be thermoformed?

- Yes, plastic sheets can be thermoformed. Thermoforming is the process of heating a plastic sheet and then shaping it into a desired form using molds or tools. It is a commonly used method for manufacturing various plastic products such as packaging, trays, and containers.

- Q: Im looking for a cheap sheet of plastic about 8 .5 feet long and 17.5 inches wide. I need it to be slippery and and make sure it wont scratch my snowboard. I live in the chicagoland area and i was wondering where i could buy a cheap sheet of plastic. i asked my local ice arena and they told me they dont have any puckboard. i know about hdpe but its to expensive. i dont wanna ship for it and id like to buy it at a plastic warehouse or a home improvement store. thanks

- ok im not really sure what your talking about but maybe try two plastic table cloths put together or new not used garbage bags?

- Q: What are the light transmission properties of plastic sheets?

- The light transmission properties of plastic sheets can vary depending on the type of plastic used. Generally, transparent plastics such as acrylic or polycarbonate have high light transmission properties, allowing a significant amount of light to pass through. However, other types of plastics, like PVC or ABS, may have lower light transmission properties due to their opacity or color.

- Q: are pvc plastic sheets and acetate sheets made from the same or similar things?

- they are different. acetate can be transparent like glass and isn't very flexible. I haven't seen clear PVC (thats not to say it doesn't exist) but it can be very flexible- like garbage bags or it can be made hard - like plastic pipes. PVC is more a group of plastics

- Q: can you stitch cross stitching patterns on plastic canvas sheets?

- Yes, as long as the design uses only full stitches. 1/4 1/2 stitches will give you problems. Size is another issue, the smallest plastic canvas is 14 count. So you won't be able to do designs that are larger than the actual size of the sheet.

- Q: Have seen many bands perform with their drummers in plastic boxes. Especially rock bands.

- The reason for this is because drums can be a very loud instrument. It can be distracting to the other musicians in the band and it is also a way of balancing the different sections of the band (even though a lot of it can be done with technology nowadays).

- Q: Are plastic sheets resistant to discoloration from cleaning agents?

- Yes, plastic sheets are generally resistant to discoloration from cleaning agents.

- Q: How do I find on the internet a plastic manufacturer that can glue two 1/4 thick sheets of acryllc together?

- The okorder These are my main suppliers but you may find others with a search for watch supplies.

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 1999 |

| Annual Output Value | US$ 10 Million |

| Main Markets | South America North America Southeast Asia Western Europe Eastern Asia Mid East Eastern Europe South Asia |

| Company Certifications | ISO 9001:2000; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 15000.00m2 |

| No. of Production Lines | 8 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | |

Send your message to us

10 Year Guarantee Anti-Flame Acrylic Plastic Sheets in Many Colors

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3000KG kg

- Supply Capability:

- 3000,000 KG Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords