Geotextile Fabric Road Construction Non-woven Polyester

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Geotextile fabric road construction non woven polyester geotextile Description:

Made from PP(polypropylene) or PET(polyester) short fiber by nonwoven needle punched

manufacturing process, it has isolation, filtration, drainage, reinforcement, protection and

maintenance etc.function

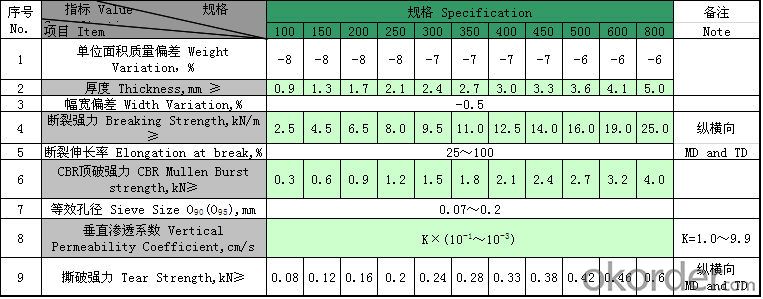

Geotextile fabric road construction non woven polyester geotextile Specification:

1.80g/m2-1500g/m2

2.1m-8m in roll width, the length as clients’request

·Technical specification of shart fiber needle punched non woven geotextile (GB/T17638-1998)

Geotextile fabric road construction non woven polyester geotextile Property:

1.Good flexibility, resistant to corrosion, resistant to acids and alkalis, anti_oxidation

2.Separation, filtration, drainage, reinforcement, protection, and maintenance function

Geotextile fabric road construction non woven polyester geotextile Application:

1.Water conservancy project and hydropower project

2.Road paving, railway

3.Airport and port

4.River bank protection and tunnel

5.Environmental protection,etc

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:What are the advantages of using geotextiles in shoreline stabilization?

- Geotextiles offer several advantages in shoreline stabilization. Firstly, they act as a barrier, preventing erosion caused by waves, tides, and currents. They effectively hold the soil in place, reducing the risk of land loss and maintaining the integrity of the shoreline. Secondly, geotextiles are permeable, allowing water to pass through while retaining the soil particles, which helps in maintaining a stable and balanced ecosystem. Additionally, they are durable and resistant to UV degradation, ensuring a long lifespan and reducing the need for frequent maintenance. Lastly, geotextiles are easy to install and cost-effective compared to traditional methods, making them a practical choice for shoreline stabilization projects. Overall, geotextiles provide a sustainable and efficient solution to protect and enhance coastal areas.

- Q:How do geotextiles help in reducing soil compaction?

- Geotextiles help in reducing soil compaction by acting as a barrier between the soil and external forces such as heavy machinery or foot traffic. They distribute the load more evenly across the soil surface, reducing the impact and preventing excessive compaction. Additionally, geotextiles can enhance drainage and filtration, allowing water to flow through the soil more easily, which helps in maintaining soil structure and reducing compaction.

- Q:Are geotextiles resistant to chemical leaching?

- Yes, geotextiles are generally resistant to chemical leaching. They are designed to have low permeability and are made from materials that can withstand exposure to various chemicals without significant degradation or leaching. However, the level of resistance may vary depending on the specific type and quality of geotextile used.

- Q:Acupuncture geotextile is divided into several kinds of how is it used?

- Acupuncture geotextile is now divided into two types, according to the fiber form to points. Continuous fiber called filament acupuncture non-woven geotextile. A few centimeters of length fibers made of staple fibers for nonwoven geotextiles. Use is not used, mainly used in geotechnical engineering in the filter, isolation, drainage and so on.

- Q:Can geotextiles be used in subgrade stabilization?

- Yes, geotextiles can be used in subgrade stabilization. Geotextiles are often used as a reinforcement material to improve the strength and stability of subgrade soils. They can help distribute the load from the overlying layers and prevent the mixing of different soil layers, thereby enhancing the overall performance and longevity of the subgrade.

- Q:Can geotextiles be used in the construction of green roofs?

- Yes, geotextiles can be used in the construction of green roofs. Geotextiles are often used as a layer in green roof systems to provide drainage and filtration, helping to manage water flow and prevent erosion. They can also help to separate different layers of the green roof system and provide stability to the growing medium.

- Q:How do geotextiles improve the performance of geomembranes?

- Geotextiles improve the performance of geomembranes by acting as a protective barrier that prevents direct contact with the underlying soil or other abrasive materials, thereby reducing the risk of punctures or damage. They also provide additional reinforcement and stability, distributing loads more evenly across the geomembrane. Additionally, geotextiles allow for better water drainage and filtration, preventing the accumulation of water pressure and enhancing the overall performance and longevity of the geomembrane system.

- Q:What are the specifications for geotextiles in drainage projects?

- The specifications for geotextiles in drainage projects typically include factors such as the material type, weight, permeability, and strength. The geotextiles should be made of durable and non-biodegradable materials such as polypropylene or polyester. The weight of the geotextiles is generally specified in terms of grams per square meter (gsm), with heavier weights often preferred for better performance. Permeability is an important factor, and geotextiles with high permeability allow for efficient water flow while preventing soil erosion. Additionally, the geotextiles should possess adequate strength to withstand installation stresses and ongoing loadings. Overall, the specifications ensure that the geotextiles effectively separate, filter, and reinforce the soil in drainage projects.

- Q:Bentonite waterproof blanket and geotextile pond construction which is good

- Pond waterproof construction, should use geomembrane

- Q:What are the key factors affecting the hydraulic conductivity of geotextiles?

- The key factors affecting the hydraulic conductivity of geotextiles include the size and shape of the geotextile fibers, the porosity of the material, the thickness of the geotextile, and the applied pressure or load. Other factors that can influence the hydraulic conductivity include the type of soil or aggregate being filtered, the presence of any clogging materials, and the overall condition and integrity of the geotextile.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Geotextile Fabric Road Construction Non-woven Polyester

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords