Wide Range of Aluminium Coil, ISO9001 Certified

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Pipeelines Covered Roofing Aluminium Coil

l Product Information

1 | Alloy | A1100 A3003 H16 H18 etc |

2 | Thickness | 0.022mm-1.5mm |

3 | Width | 200mm-1600mm |

4 | Standard width | 1240mm 1250mm 1260mm |

5 | Coating face | PE or PVDF |

6 | Gloss | meet the customer requirement |

7 | PVDFcoating | more than 25 micron |

8 | PE coating | more than 18 micron |

9 | Surface treatment | brushed |

10 | Colors | various colours to choose |

11 | Application | Acp, HPL, fireproof board, building decoration materials etc |

12 | Features | anti-corrosion durable |

l Packaging & Delivery

Packaging detail: Sea Worthy Wooden pallet

Delivery detail: About 25 days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium Products have been our featured products. We have specialized in aluminium products for about a decade and have sold our good quality aluminium products to the worldwide.

l CNBM World Wide

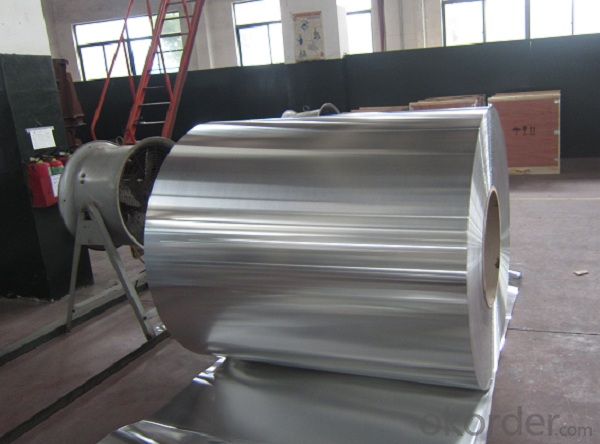

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q:What are the common surface defects or issues in aluminum coils?

- Some common surface defects or issues that can be found in aluminum coils include: 1. Scratches: These are visible marks on the surface of the coil caused by contact with abrasive materials or improper handling during production, transportation, or storage. 2. Streaks: Streaks are long, narrow lines or bands that appear on the surface of the coil. They are often caused by irregularities in the rolling process or the presence of impurities in the aluminum material. 3. Dents: Dents are localized depressions or deformations on the surface of the coil. They can occur due to mishandling, accidental impacts, or improper storage practices. 4. Corrosion: Aluminum is generally resistant to corrosion, but certain environmental conditions or exposure to corrosive agents can lead to the formation of oxide layers or pitting on the surface of the coil. 5. Edge cracks: These are cracks or fissures that occur along the edges of the coil. They can be caused by improper cutting or shearing techniques during the manufacturing process. 6. Surface roughness: Surface roughness refers to an uneven or bumpy texture on the surface of the coil. It can be a result of inadequate smoothing or finishing during the rolling or processing stages. 7. Oil stains: Oil stains are dark or discolored areas that appear on the surface of the coil. They can occur due to improper cleaning or lubrication during the production process. 8. Coil set: Coil set refers to the tendency of the coil to retain a curvature or shape after unwinding. It can be caused by stresses induced during rolling, coiling, or cooling, leading to a non-flat and uneven surface. 9. Roll marks: Roll marks are patterns or imprints left on the surface of the coil by the rolling mill or equipment. They can be caused by uneven pressure or improper alignment of the rolling tools. 10. Discoloration: Discoloration refers to changes in the color or appearance of the aluminum surface. It can occur due to exposure to high temperatures, chemical reactions, or oxidation. These surface defects or issues can negatively impact the appearance, quality, and performance of aluminum coils. Manufacturers and users should be aware of these defects and take appropriate measures to prevent or minimize their occurrence.

- Q:Can aluminum coils be used in the production of electrical transformers?

- Yes, aluminum coils can be used in the production of electrical transformers. Aluminum is a lightweight and cost-effective material that offers many advantages in transformer manufacturing. While copper has traditionally been the preferred choice for transformer windings, aluminum is becoming increasingly popular due to its lower cost and weight. Aluminum coils have good electrical conductivity and high thermal conductivity, which are essential for efficient transformer operation. Moreover, aluminum coils are easier to handle and install due to their lighter weight. However, it is important to note that aluminum coils require larger cross-sectional areas compared to copper coils to achieve the same electrical conductivity. Additionally, aluminum coils may require additional measures to mitigate the effects of aluminum's higher coefficient of expansion, such as using proper insulation and mechanical support. Overall, aluminum coils can indeed be used in the production of electrical transformers, offering a viable alternative to copper coils in certain applications.

- Q:This is not for around the house. It is for my lab. I am pretty sure these one wires are Aluminum, but I need the connector they were made with and the power cable is copper. Would it be okay to still try to join the two.

- different metal heat at a different rate use oxigaurd and wire nuts

- Q:How are aluminum coils used in the production of gutters and downspouts?

- The production of gutters and downspouts relies heavily on aluminum coils. These coils serve as the main material for manufacturing seamless gutters, which are renowned for their durability, longevity, and aesthetic appeal. To initiate the production process, specialized gutter machines are utilized to feed the aluminum coils. These machines shape the coils into the desired gutter profile, usually in the form of a lengthy continuous piece. Subsequently, the coil is cut into appropriate lengths that correspond to the measurements required for a specific building or project's gutter system. Once cut, the aluminum coil undergoes various bending and folding techniques to shape and form it. This transformation allows the coil to assume the seamless gutter shape necessary for efficiently collecting and channeling rainwater away from a building's roof and foundation. The seamless design eliminates the risk of leaks and enhances the overall functionality of the gutter system. Moreover, the aluminum coils used in gutter production offer several advantages. Firstly, aluminum is lightweight yet sturdy, making it an ideal material for gutters and downspouts. It possesses resistance to rust and corrosion, ensuring the longevity of the gutter system even in harsh weather conditions. Additionally, aluminum is highly malleable, enabling customization of shapes and sizes to meet the specific requirements of different buildings. In conclusion, aluminum coils play an integral role in the production of aesthetically pleasing, durable, and highly functional gutters and downspouts. Their use as the primary material guarantees long-lasting performance, resistance to corrosion, and customization options to cater to various architectural needs.

- Q:I have a couple aluminum baking sheets, and when i wash them, then dry them with a towel, it turns the towel black? why is this? are these still ok to use? Ive been putting one of those silicone baking sheets or parchment paper on the sheets because of this. but i cant really do that with the cake pan. so how do i stop it from doing this?

- I means that they are very inexpensive. Aluminum does this when it 's been in soapy water. Use the baking sheets just to be safe until you can get some others of a higher quality.

- Q:I recently had to have a course of B-12 injections (my digestive system was not properly absorbing other forms). While I felt a significant improvement in mood, energy and memory, I was very concerned to discover that the B-12 shot came with a little something extra: aluminum! I'm wondering if the benefits outweigh the potential risks - why is aluminum placed in the injection? (Are there metal free versions out there?)

- Aluminum salts have been used in vaccines for over 80 years now. They are thought to increase the body's immune response to the vaccines although it is not clear to researchers how this works. However, there is no evidence that it is harmful and the only side effect seems to be increased reddness. The odd thing is that there is usually some sort of metal in any vaccine/shot. If not aluminum salts, there's thimerosal (a mercury-based preservative). The CDC says, btw, that there is no proof that thimerosal causes any harm. However, some studies show a link between thimerosal, aluminum, and a host of other preservatives added to vaccines to autism in children. No news on how it affects adults, but research is being done with respect to Alzheimer's disease. Speak to your doctor to find out he/she has 'metal free' versions of vaccines and about your concerns. Such vaccines are available but are usually very costly to obtain manufacture so doctors usually don't order them as a result.

- Q:How are aluminum coils tested for flatness?

- Aluminum coils are tested for flatness using various methods to ensure they meet the required standards. One common method is through the use of a straight edge, where a long, precision straight edge is placed on the surface of the coil. Technicians then visually inspect for any gaps or deviations between the straight edge and the coil's surface. If any gaps are found, it indicates that the coil is not flat and further analysis is required. Another method used is the straight edge ruler technique, where a ruler with a thin, flexible edge is placed on the coil's surface. By applying gentle pressure, technicians can identify any areas where the ruler does not make full contact with the coil, signaling irregularities in the flatness. Advanced techniques such as laser or optical methods are also employed to assess the flatness of aluminum coils. These methods use laser beams or optical sensors to measure the surface profile of the coil. The data collected is then analyzed to determine if any deviations from the desired flatness exist. These techniques provide accurate and precise results, allowing for a more detailed evaluation of the coil's flatness. Overall, the testing of aluminum coils for flatness is crucial to ensure that the coils meet the required standards for various applications. By employing a combination of visual inspection, straight edge techniques, and advanced laser or optical methods, manufacturers can ensure that the coils are flat and free from any irregularities that could affect their performance.

- Q:Can aluminum coils be used in vacuum applications?

- Indeed, aluminum coils are capable of being employed in vacuum applications. Aluminum, being a frequently utilized substance in vacuum systems, possesses exceptional attributes including low outgassing, high thermal conductivity, and commendable corrosion resistance. Consequently, these qualities render aluminum coils suitable for a diverse array of vacuum applications, encompassing, but not restricted to, vacuum chambers, vacuum pumps, cryogenic systems, and particle accelerators. Nevertheless, it is crucial to acknowledge that aluminum may react with particular gases or chemicals. Hence, it is imperative to carefully evaluate the specific necessities and compatibility of the vacuum application prior to employing aluminum coils.

- Q:Automotive aluminum coil, using GB H22, what brand, what are the main ingredients?

- In the corresponding foreign brands for AlMg3, 5754 different heat treatment is the automobile manufacturing industry (car door, mould, seals), main materials used for canning industry

- Q:1) Do you recycle aluminum (soda cans, etc.)?2) Why do or don't you recycle aluminum?3) Does it make a difference to the economy whether we recycle or not?4) Does it make a difference to the environment whether we recycle or not?5) What do you think would help people to recycle more? Such as a reward, information, resources, etc. Don't feel the need to limit responses. Thank you.

- no I dont recycle aluminum but I should have no place to store it yes it makes a difference because in stead of making more they can melt down what has already been made the contamination to our environment would be less I think re teaching about recycling an where to turn them in would be good along with showing how the aluminum impacts our environment when its not recycled would work

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wide Range of Aluminium Coil, ISO9001 Certified

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords