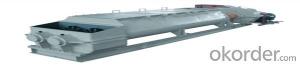

brick making machine-two stage vacuum extruder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description: It is an extruding & molding equipment with strong points of reasonable distribution of grains, homogeneity of moisture content, fit for raw material with low plastic nature. It is suitable for material such as coal gangue, fly ash mixture, shale, clay, etc. It adopts hard gear reducer. Use powerful or oil lubricant, with long life span, and it can guarantee the extruding pressure. Clutch is operated by electro or pneumatic, easy to realize automatic control.

Technical Parameter:

Type | Diameter of reamer of extruding end (mm) | Capacity (pieces(standard brick size)/h) | Authorized pressure(Mpa) | Vacuum Degree(Mpa) | Installed capacity(kw) | Dimension(mm) |

JKY70/70-2.5 | 700 | 19000~24500 | 2.5 | -0.092 | 250+90+1.5 | 6687×6765×2846 |

JKY70/60-3.8 | 600 | 14000~15000 | 3.8 | -0.092 | 250+90+2.2 | 6632×6855×2866 |

JKY60/60-4.0 | 600 | 21000~24480 | 4.0 | -0.092 | 250+90+7.5+1.5 | 4819×6416×3065 |

JKY60/50-4.0 | 500 | 12000~18000 | 4.0 | -0.092 | 200+75+1.5 | 5844×6102×2796 |

JKY50/50-4.0 | 500 | 12200~13420 | 4.0 | -0.092 | 200+90+7.5+1.5 | 6904×5352×2820 |

JKB50/45-3.0 | 450 | 9800~15100 | 3.0 | -0.092 | 132+55 | 5375×4521×2723 |

JKR50/45-2.0 | 450 | 12000~16000 | 2.0 | -0.092 | 110+55 | 4900×4204×2723 |

- Q: Fly ash Mianshao brick machine is not a kind of construction waste with coal ash to do brick, who understand this thing?

- As a result of automatic hydraulic molding machine with a high degree of automation, suppression of large, good quality products, high yield characteristics, has long been a brick-free production line of the preferred equipment. This Mianshaozhuanji has a wide range of materials applicable to the ability to use a variety of materials to prepare Mianshaozhuan; this equipment has a compact structure, large pressing, rigid, fully sealed dust, circulation lubrication, simple operation, high yield, D

- Q: Burning brick and autoclaved lime sand brick what different

- Also known as aerated blocks, aerated bricks, mainly used for high-rise building filling, do the wall. The size of the brick can be combined with the need to cut.

- Q: What kind of configuration does the small semi-automatic cement brick machine include?

- Buy brick equipment to find those who do the best export manufacturers, manufacturers can do the export of comprehensive technical strength are very tough.

- Q: Cement brick machine brick machine advantages

- Cement hollow brick machine using the most advanced technology, transmission power, smooth operation, in place accurate, low maintenance rate advantages.

- Q: The development of brick machine

- Brick machine has been exported abroad, have their vigorous figure.

- Q: Where is the brick of the tiles used to make the brick better?

- Its role: 1, with good water permeability, breathability, can quickly penetrate the rain, add soil water and groundwater, to maintain soil moisture, improve the urban ground plants and soil microbial living conditions.

- Q: How can a free brick brick brick machine be classified?

- According to the empty arrangement: divided into single row of holes, double row of holes, multi-row of blocks.

- Q: What is the principle of vacuum brick machine

- The sealing surface of each bonding surface, the bonding surface and the bonding surface of the connecting member with the vacuum box are required to ensure the machining precision, and the bonding surfaces are in good contact. Assembly, the combination of surface coated with a vacuum sealant, and then even imprison the various parts of the bolt.

- Q: Cement brick machine related issues

- There are many types of cement brick machine, mainly to see what kind of brick you need to produce, and now the main use of a kind of eight-hole turntable, this machine equipment using a wide range of raw materials, the machine's main features are: Convenient, with pressure display, mechanical failure alarm, power supply distance protection, automatic control of oil supply, easy installation and other functions.

- Q: Free burning brick brick brick machine can be how to classify

- According to the empty form: divided into square hole block and round hole block.

Send your message to us

brick making machine-two stage vacuum extruder

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords