CT18 Brick Making Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name:CT18 Block Making Machine

Ⅰ. Specifications of CT18 Block Making Machine

Daily Production Capacity: 7200 (390*190*190mm)With long-distance control function.

Rigidity synchroizer in the way of crutched arms, which avoid the green blocks demaged when mould frame lifting.

Integrated vibrating bin and vibrating table, improve reliable of vibrating table.

Advance vibration technology, feeding and forming by different vibrating model assures high quality of feeding and forming.

This machine is suitable for customers with small or medium amount of investment.

Technical Parameter:

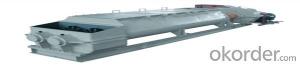

Dimension: 6600*2090*3000mm Viration Type: Table vibration

Rating pressure: 21MP Frequency: 2800-4500r/min

Pallet size: 1100*560mm Cycle time: 11-25sec.

Power: 35KW

Ⅱ. Features of CT18 Block Making Machines

- powered by petrol, diesel or electric motors.

- controls can be manual, semi-automatic or fully automatic.

- uses vibration and hydraulics to form blocks or bricks.

- change mould are available and it can shape different blocks and bricks.

- typically made from hardened steel or cast to withstand the strain of construction sites.

- These machines are manufactured and install to provide a user friendly design to be used by unskilled worker. They are also efficient and can therefore be used by small and medium enterprises as well as larger operations.

- The multi-functional machines can produce all kinds of products from the wall materials of new-style into products used in manicipality, garden, road paving, water conservancy, airport and wharf etc.

Ⅲ. Technical specification of CT18 Block Making Machine:

|

Mainframe Dimension |

4950x2950x4750mm |

|

Vibration |

Table vibration |

|

Pallet size |

1400x1300mm |

|

Power |

85kw |

|

Rating pressure |

21MPa |

|

Vibration frequency |

2800-4500r/min |

|

Cycle time |

15-25sec. |

|

Items |

Size (LxWxH) |

Pcs./mould |

Pcs./hour |

Pcs./8hours |

One year(300days) production |

|

Blocks |

390x190x190mm |

18 |

3,240 |

25,920 |

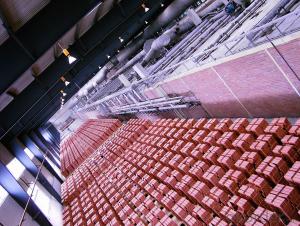

7,776,000 |

|

Porous Bricks |

240x115x90mm |

50 |

12,000 |

96,000 |

28,800,000 |

|

Solid Bricks |

240x115x53mm |

95 |

22,800 |

182,400 |

54,720,000 |

|

Holland Bricks |

200x100x60mm |

60 |

8,640 |

69,120 |

20,736,000 |

Ⅳ. Advantages and benefits of having a block making machine:

1. you cut out the middle man in the production of bricks and blocks.

2. customize the machine you buy to suit your operation perfectly.

3. save time and money on transportation cost by producing blocks and bricks on site.

4. choose between different moulds to fit the project specifications.

5. be guarantee the quality of bricks and blocks you produce instead of depending on another company’s workmanship.

6. flexible production schedules can ensure optimization of resources and man-power.

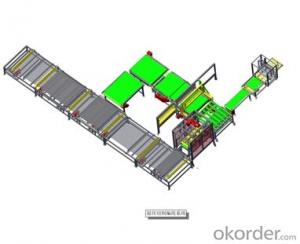

Invest scale you can made:

We got from simple line to fully automatic production line. Our experts can give good advice for each customer according to your needs for saving investment.

- Q: What kind of configuration does the small semi-automatic cement brick machine include?

- Buy brick equipment to find those who do the best export manufacturers, manufacturers can do the export of comprehensive technical strength are very tough.

- Q: Brief introduction of cement brick machine

- Can be said to invest less, quick, is a lot of investors to invest in the popular industry.

- Q: Brief introduction of the brick machine

- The purpose of the utility model is to realize an integrated hydraulic brick making machine comprising a main engine, an automatic conveying device, a hydraulic control device, a hopper, a hydraulic platform, a mixer, a hydraulic pallet conveyor, a pallet box, Valve handle, mold sets, die indenter, raw material hydraulic conveyor, pallet.

- Q: Cement brick machine brick machine advantages

- Cement hollow brick machine has the characteristics of compact structure, large pressing force, strong rigidity, fully sealed dustproof, circulating lubrication, simple operation, high output and durable.

- Q: Maintenance method of fly ash brick machine

- the quality of personnel to participate in maintenance is low, can not follow the maintenance of the operating procedures, there is no corresponding maintenance records.

- Q: Where is the brick of the tiles used to make the brick better?

- the surface was slightly bump, to prevent road reflection, to absorb the noise generated when driving the vehicle, can improve the vehicle traffic comfort and safety.

- Q: What is the difference between a vacuum brick machine and an ordinary brick machine?

- In the water, because the vacuum brick machine is the first vacuum and water re-sintering, natural than ordinary brick coal time is short, forming fast.

- Q: Hollow block brick brick machinery in use should pay attention to what the problem to ensure the normal operation of the brick machine?

- Second: the use of often check the mold size, welding joint parts of the situation, there weld cracks, should be promptly repaired, there is excessive wear to adjust the aggregate size, wear and tear over the impact of product quality need to reprovision a new model;

- Q: Brick machine operating procedures

- When the material in the rotary disk die hole is completely pressed, the main motor is turned off and the brick waste in the mold hole is cleaned. If you stop for a long time, you should disconnect the current. After stopping, should be the machine moving components of the connection bolts, oil cups, bearings and other preventive checks.

- Q: Free burning brick brick brick machine can be how to classify

- According to the structure of the block: divided into a back cover block, not the back of the block, slot block, a slot block.

Send your message to us

CT18 Brick Making Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords