excellent wet brick cutting system with best price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

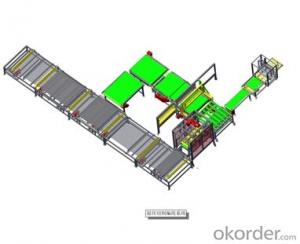

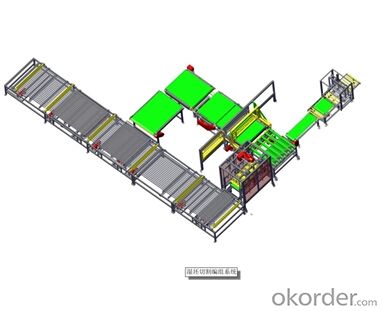

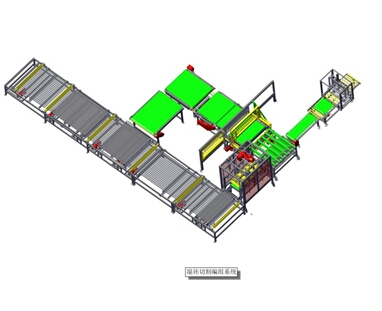

In this system, it is including of automatic wet brick cutting machine, speed-up belt, direction-change and speed-up belt, block cutting machine, direction-change belt, turning belt, converyor, automatic cutting machine.The working process is automatically controlled by PLC.

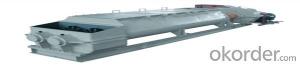

| Type | Production capacity (brick/hour) | Brick number/cutting | Installed capacity | Weight(kg) | Dimension(m) |

| ZQPSB32B | 28000 | 32 | 9 | 2257 | 6.0X3.0X1.9 |

| ZQPDB16 | 20000 | 16 | 11+1.5 | 2180 | 6.0X2.6X2.0 |

| ZQPG24 | 26000 | 24 | 4.75 | 1500 | 4.8X1.8X1.7 |

| ZQPG32 | 35000 | 36 | 6.25 | 1850 | 5.9X2.2X1.7 |

- Q: What kind of configuration does the small semi-automatic cement brick machine include?

- Buy brick equipment to find those who do the best export manufacturers, manufacturers can do the export of comprehensive technical strength are very tough.

- Q: What are the brick-making materials?

- The brick machine is made of stone powder, sand, industrial waste, slag, slag and other raw materials for the brick, adding cement to produce brick machinery and equipment, through the replacement of mold, the production of different types of bricks such as tiles, blocks, bread bricks, , Slope protection brick.

- Q: Maintenance method of fly ash brick machine

- due to the harsh environmental conditions of the site restrictions, technical maintenance is not in accordance with the provisions of the maintenance "amount", but what care and what care to see what maintenance.

- Q: Automatic concrete brick machine bearing how to choose?

- When the fully automatic concrete brick making machine is running, it should always check whether the bearing seal of the equipment is. The grease in the bearing seat should be filled once every month. Every three months should be cleaned and replaced with oil frying. Normal after feeding, feeding together to be uniform, should be avoided mixed with iron hard objects;

- Q: Installation and commissioning of hydraulic press

- The factory of the machine in accordance with the relevant provisions of the factory have made the factory test, but due to long-distance transport and a long time to place and other reasons, the installation of hydraulic brick should be the following checks:

- Q: How can a free brick brick brick machine be classified?

- According to the empty arrangement: divided into single row of holes, double row of holes, multi-row of blocks.

- Q: What is the difference between a vacuum brick machine and an ordinary brick machine?

- Generally speaking, ordinary brick machine can only produce standard brick, and vacuum brick machine can not only produce standard brick, but also the production of porous hollow brick.

- Q: Hollow block brick brick machinery in use should pay attention to what the problem to ensure the normal operation of the brick machine?

- Fifth: replace the mold, clean, oil rust, should be set to dry, flat at the support pad flat to prevent gravity deformation.

- Q: What is the principle of vacuum brick machine

- Vacuum brick machine in the work of the noise is relatively low, compared to the savings in power consumption, savings rate up to 40 percent, vacuum brick machine in the degree of automation is relatively high, the size of brick and brick The strength of the equipment after the set, the equipment in the production of products can not meet the requirements of the set will return to the raw material warehouse, and then carried out after the re-row to repress, can make the production of products to ensure that the larger The guarantee.

- Q: Cement brick machine related issues

- There are many types of cement brick machine, mainly to see what kind of brick you need to produce, and now the main use of a kind of eight-hole turntable, this machine equipment using a wide range of raw materials, the machine's main features are: Convenient, with pressure display, mechanical failure alarm, power supply distance protection, automatic control of oil supply, easy installation and other functions.

Send your message to us

excellent wet brick cutting system with best price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords