Black EPDM Waterproof Rubber Sheets High Tensile Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Rubber Waterproof Membrane

Product Instruction:

EPDM waterproof membrane is made from ternary ethylene-propylene rubber,which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

CNBM own the wold-advanced equipment of cold feeding extrusion and continuous vulcanization technology. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or cracked under normal building movement.

Product Features:

-Excellent weather-ability, durability and size stability

-Good adaptability to high and low temperature, UV resistant and anti-corrosion

-High tensile strength and good elongation, accommodating to structure movement

-Easy installation, solid joint, and mo environmental pollution

-Good rooting penetration resistance

-Service life up to 50 years

Applications:

-Roof, basement, tunnel, pond liner, dam

-Industrial and civil building waterproofing

-Geosynthetic liner for fish ponds, swimming pools, channels, irrigation system

-Especially suitable for projects with high requirement in durability, anti-corrosion and deformation

Specifications:

-Width of roll: 1.2m, 2m, 4m

-Length of roll: 20m, 30m or customized

-Thickness of membrane: 1.2mm, 1.5mm, 2mm

-Type: vulcanized EPDM or welding EPDM

-Application: roof, basement, pond, lake, swimming pool, steel structure roofing, underground, tunnel, etc

FAQ:

1. Is your EPDM waterproof membrane the real rubber?

Yes, our EPDM membrane is made from top quality rubber, which is imported from America. We support samples for testing, or testing in our factory.

2. How's your products quality?

Our EPDM is with the top quality at home and abroad. Our quality is much higher than Chinese standard. Our product is widely used in Chinese Central government projects. And it's also accpted by customers all over the world, such as EU, USA, Astrulia, etc.

3. What's the service life of your EPDM membrane?

The service life of our EPDM membrane is more than 50 years.

4.What's your MOQ?

Our MOQ is 3000M2.

5. What's your product ability of EPDM membrane?

We own the largest EPDM production line in China. Our product ability of EPDM membrane reaches 2 million square meter per year.

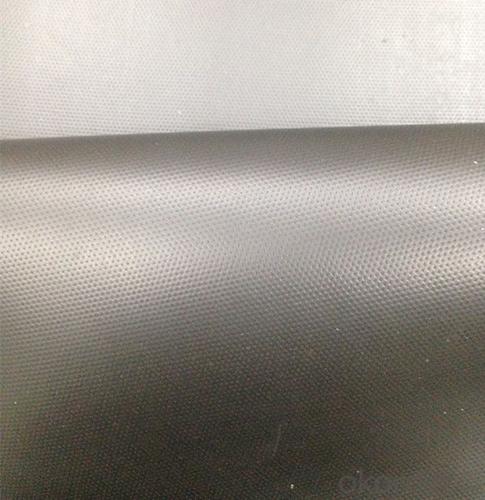

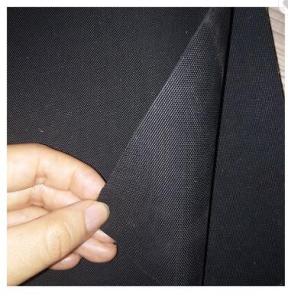

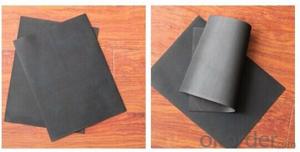

Photos:

- Q: Can a waterproofing membrane be used on flat roofs?

- Flat roofs can indeed benefit from the use of a waterproofing membrane. This method is widely recognized as one of the most effective and commonly used techniques for achieving waterproofing on flat roofs. The membrane itself is a thin material that is carefully applied to the roof's surface in order to prevent any water from seeping through. Typically constructed from durable and flexible substances like synthetic rubber or modified bitumen, the membrane is designed to withstand harsh weather conditions and offer long-lasting protection. By installing the membrane in overlapping layers, a continuous barrier is created that effectively seals the roof, preventing any water leakage into the building. Additionally, it is worth noting that waterproofing membranes can also provide insulation and energy efficiency advantages, which further contributes to their popularity in flat roof applications.

- Q: 3MM thick, one square meter waterproof membrane SBS price?

- 3, waterproofing membrane is mainly used for building walls, roofs, and tunnels, highways, landfills, etc., to withstand the external rain, groundwater leakage can be rolled into a roll of flexible building materials, as There is no leakage connection between the foundation of the project and the building, which is the first barrier to the whole project waterproofing and plays a vital role in the whole project.

- Q: How does a waterproofing membrane compare to other waterproofing methods?

- Compared to other traditional waterproofing methods, a waterproofing membrane stands out in several ways: 1. Unmatched Protection: When it comes to keeping water out, a waterproofing membrane is unparalleled. Unlike waterproof paints or coatings, which may crack or peel, a membrane forms a continuous and seamless barrier that can withstand extreme weather conditions. 2. Long-Lasting: Designed to be durable, waterproofing membranes are made from materials like rubber, PVC, or modified bitumen that resist wear and tear. This ensures that they provide a reliable waterproofing solution for many years. 3. Versatility at its Best: Waterproofing membranes can be applied to various surfaces, including concrete, metal, and wood. They are suitable for a wide range of applications such as roofs, basements, foundations, and tunnels, making them ideal for both residential and commercial projects. 4. Flexible and Adaptable: Thanks to their flexibility, waterproofing membranes conform to the shape and contours of the surface they are applied to. This quality allows them to accommodate any structural movements or shifts, preventing potential cracks or gaps that could lead to water leakage. 5. Easy to Install: Professionals or experienced DIYers can easily install waterproofing membranes. The process involves rolling out the membrane onto the surface, adhering it with adhesive or heat-welding, and sealing the edges and seams. This simplicity of installation makes it a popular choice for new construction and retrofit projects alike. 6. Cost-Effective Investment: Although the initial cost of installing a waterproofing membrane may be higher compared to other methods, its long-term cost-effectiveness makes it a wise investment. The durability and longevity of the membrane result in fewer maintenance and repair costs over time, saving money in the long run. In conclusion, a waterproofing membrane surpasses other waterproofing methods in terms of protection, longevity, versatility, flexibility, ease of installation, and cost-effectiveness. Its ability to provide a continuous and reliable barrier against water intrusion makes it the preferred choice for many construction projects.

- Q: Is a waterproofing membrane resistant to hydrocarbons or oil spills?

- Typically, a waterproofing membrane exhibits resistance against hydrocarbons and oil spills. Its primary purpose is to create a barrier that prevents water penetration and protects the underlying surfaces from moisture damage. These membranes are commonly made from materials such as modified bitumen, polyurethane, or PVC, all of which possess excellent chemical resistance, including towards hydrocarbons and oil. This resistance guarantees that the membrane remains intact and effective even when exposed to substances like oil spills or hydrocarbon-based liquids. However, it is crucial to note that the specific resistance may vary depending on the type and quality of the selected waterproofing membrane. Therefore, it is essential to choose a membrane that is specifically engineered to withstand the intended environment and potential chemical exposures.

- Q: Are there any specific considerations for installing a waterproofing membrane on wood surfaces?

- Yes, there are several specific considerations when installing a waterproofing membrane on wood surfaces. First and foremost, it is important to ensure that the wood surface is clean, dry, and free from any dirt, dust, or debris. This will help to create a proper bond between the wood and the waterproofing membrane. Additionally, it is crucial to choose a waterproofing membrane that is specifically designed for wood surfaces. There are different types of membranes available, such as liquid-applied membranes or sheet membranes, so selecting the right one is essential. Before applying the membrane, it is advisable to prime the wood surface with a suitable primer. This will help to enhance the adhesion of the membrane and provide a more durable and long-lasting waterproofing solution. It is also important to consider the climate and weather conditions in the area where the wood surface is located. If the area is prone to extreme temperatures or heavy rainfall, it is recommended to choose a waterproofing membrane that can withstand these conditions and provide adequate protection. Furthermore, proper installation techniques should be followed to ensure the membrane is applied correctly. This may involve rolling or brushing the membrane onto the wood surface, as per the manufacturer's instructions. It is crucial to pay attention to details such as seams, corners, and edges to ensure a watertight seal. Regular maintenance and inspection are essential for the longevity of the waterproofing membrane on wood surfaces. It is important to check for any signs of damage, such as cracks or peeling, and address them promptly to prevent water infiltration and potential damage to the wood. In summary, when installing a waterproofing membrane on wood surfaces, it is crucial to prepare the surface properly, choose the right type of membrane, consider the climate and weather conditions, follow proper installation techniques, and perform regular maintenance and inspection. By doing so, you can effectively protect the wood surface from water damage and ensure its longevity.

- Q: Can a waterproofing membrane be used on green roofs?

- Yes, a waterproofing membrane can be used on green roofs. In fact, it is an essential component of the green roof system. A green roof is designed to have vegetation and soil on top of a waterproofing layer, which prevents water from seeping into the underlying structure. The waterproofing membrane acts as a barrier, protecting the roof and building from moisture damage. It ensures that water is properly drained and does not cause leaks or structural issues. However, it's important to select a waterproofing membrane that is specifically designed for green roof applications, as it needs to be able to withstand the unique demands of a green roof environment, such as root penetration and constant exposure to moisture.

- Q: Can waterproofing membranes be used on underground tunnels?

- Yes, waterproofing membranes can be used on underground tunnels. These membranes are specifically designed to provide protection against water infiltration and can be applied to the tunnel walls and floors to prevent water ingress. The membranes create a barrier that keeps the tunnel dry, ensuring its structural integrity and preventing damage from moisture.

- Q: Can a waterproofing membrane be used on stadium seating areas?

- Yes, a waterproofing membrane can be used on stadium seating areas. Waterproofing membranes are typically used to protect structures from water damage, including roofs, basements, and decks. Stadium seating areas are often exposed to the elements, including rain and snow, which can lead to water damage if not properly protected. By applying a waterproofing membrane, the seating areas can be safeguarded against water infiltration, preventing potential issues such as mold growth, deterioration of materials, and structural damage. It is important to choose a high-quality waterproofing membrane that is specifically designed for outdoor use and can withstand heavy foot traffic, ensuring long-lasting protection for the stadium seating areas.

- Q: Can waterproofing membranes be used on buried pipelines?

- Yes, waterproofing membranes can be used on buried pipelines. Waterproofing membranes are designed to provide a protective barrier against water and moisture, and they can be applied to various surfaces, including buried pipelines. The membranes are typically made of materials such as bitumen or synthetic polymers, which are resistant to water penetration. When applied to buried pipelines, waterproofing membranes help prevent water infiltration, which can cause corrosion and deterioration of the pipeline material. They act as a barrier, preventing water from reaching the pipeline's surface and protecting it from potential damage caused by moisture. Additionally, waterproofing membranes also offer protection against other external factors, such as soil chemicals or gases, which can potentially cause harm to the pipeline. By creating a waterproof barrier, the membranes help extend the lifespan of buried pipelines, reduce maintenance costs, and improve overall performance. It is important to note that the selection and application of waterproofing membranes should be carried out by professionals who are knowledgeable in pipeline construction and waterproofing systems. Proper installation techniques and compatibility with the pipeline material are crucial to ensure the effectiveness of the waterproofing membranes.

- Q: Can a waterproofing membrane be used on precast copper surfaces?

- Precast copper surfaces can indeed utilize a waterproofing membrane. These membranes possess adaptability and can be utilized across a diverse range of surfaces, including copper. Their primary purpose is to establish a protective barrier that hinders water infiltration and safeguards the underlying structure from moisture-induced harm. With accurate application, a waterproofing membrane can proficiently seal precast copper surfaces, securing enduring defense against water intrusion. Nevertheless, it is vital to verify the compatibility of the membrane with copper and conduct thorough surface preparation to guarantee optimal adhesion and performance.

Send your message to us

Black EPDM Waterproof Rubber Sheets High Tensile Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords