Black EPDM Rubber Waterproofing Membrane applt to Bridge/Road

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

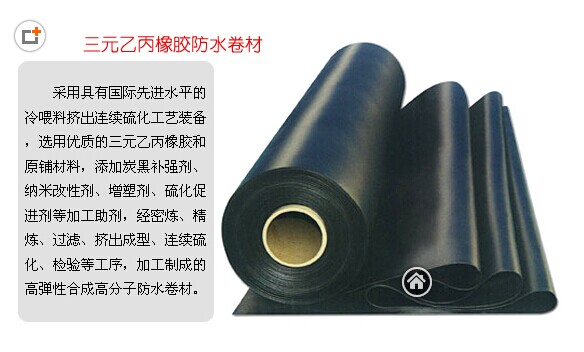

EPDM waterproofing Rubber membrane

1. Product Feature for EPDM Waterproofing Membrane:

a. UV resistant and anti-corrosion

b. High tensile strength and good elongation.

c. Easy installation, solid joint, and no environmental pollution

d. Good rooting penetration resistance

e. Service life up to 50 years

2. Detail Specification of EPDM Waterproofing Membrane:

Type | EPDM Waterproof Membrane | ||

Material | EPDM Rubber | ||

Thickness | 1.2mm | 1.5mm | 2.0mm |

Weight(kg/m2) | 1.54-1.58 | 1.79-1.83 | 2.25-2.29 |

Size | 1.2m(width) * 20m(length)/roll | ||

Type | Vulcanized & Weldable | ||

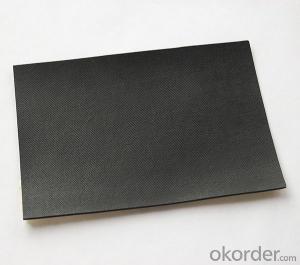

Pattern | Non-reinforced(homogeneous) | ||

Packing | 24sqm/roll, with plastic bag | ||

Color | Black | ||

Application | Roof, basement, pond, Lake, steel structure roof, swimming pool, underground, tunnel, etc | ||

3. Technical Sheet of EPDM Waterproofing Membrane:

No. | Item | Technical index | ||

JL1 | JF1 | |||

1 | Tensile strength at break Mpa | Normal temperature≥ | 7.5 | 4.0 |

60°C≥ | 2.3 | 0.8 | ||

2 | Elogation at break | Normal temperature≥ | 450 | 400 |

-20°C≥ | 200 | 200 | ||

3 | Tearing strength KN/m≥ | 25 | 18 | |

4 | Impermeability 30minutes No leak | 0.3Mpa | 0.3Mpa | |

5 | Low temperature flexibility °C≤ | -40 | -30 | |

6 | Heat air ageing 80°C x 168h | Tensile strength retention rate % ≥ | 80 | 90 |

Elogation retention rate % ≥ | 70 | 70 | ||

Apperance of 100% elogation | no crack | no crack | ||

4. Application of EPDM Waterproofing Membrane:

(1) Roofs, Basement, Toilets

(2) Industrial and civil building waterproofing

(3) Geosynthetic liner for swimming pool, channels, irrigation system

(4) Especially suitable for projects with high requirements in durability, anti-corrosion and deformation

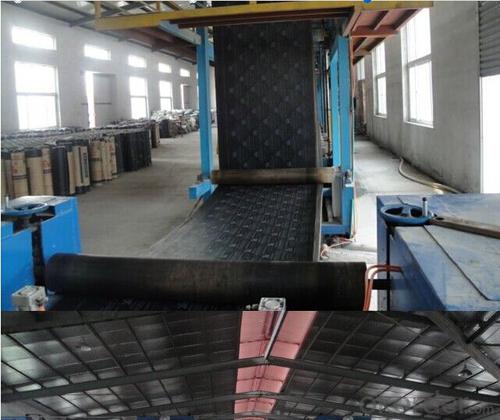

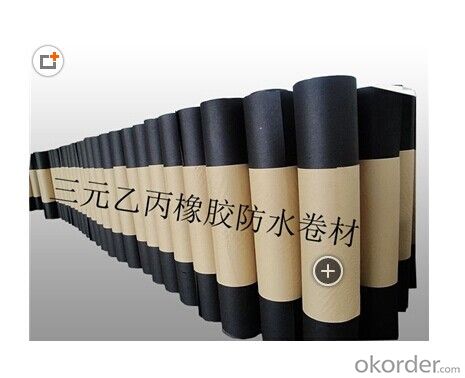

4. Some photos:

- Q: Are waterproofing membranes suitable for residential basements?

- Yes, waterproofing membranes are suitable for residential basements. These membranes are designed to prevent water infiltration and protect the basement against moisture damage. They create a barrier that keeps water out, helping to keep the basement dry and free from water-related issues like mold and water damage.

- Q: Can a waterproofing membrane be used for a school?

- Yes, a waterproofing membrane can be used for a school. Waterproofing membranes are commonly used in construction to prevent water penetration and protect buildings from moisture damage. Installing a waterproofing membrane in areas such as basements, roofs, or exterior walls can help keep the school building dry and safeguard against potential water-related issues.

- Q: What kind of waterproofing membrane, waterproofing membrane is how to classify their respective advantages?

- Waterproof membrane classification are: EPDM waterproofing membrane, SBS asphalt membrane, PVC waterproofing membrane, TPO waterproofing membrane. Advantages and Disadvantages

- Q: Can a waterproofing membrane be used on both residential and commercial buildings?

- Certainly, both residential and commercial buildings can benefit from the application of a waterproofing membrane. These membranes are specially crafted to create a shield against water infiltration, making them indispensable for any structure, whether it be a home or a business establishment. Be it a dwelling, a multi-unit complex, a corporate office, or a retail store, the versatile waterproofing membrane can be effortlessly applied to a variety of surfaces, including roofs, walls, foundations, and basements, effectively safeguarding the building from the perils of water damage and seepage. Furthermore, these membranes come in a wide array of types and materials, ensuring that they can be tailored to meet the specific needs and demands of any building, regardless of its residential or commercial nature.

- Q: Does a waterproofing membrane require a protective layer?

- Yes, a waterproofing membrane typically requires a protective layer. The protective layer helps to shield the membrane from various external factors, such as UV rays, weather conditions, mechanical damage, and chemical exposure, thereby enhancing its durability and longevity.

- Q: Can a waterproofing membrane be installed by a homeowner or is professional installation required?

- Although a homeowner can technically install a waterproofing membrane, it is strongly advised to enlist the services of a professional. Several factors must be taken into consideration, making professional installation the superior choice. To begin with, proper installation of waterproofing membranes necessitates specific knowledge and expertise. Professionals are trained in the correct techniques and possess experience working with various membrane types. They understand the intricacies of the process, including surface preparation, membrane application, and sealing. This expertise guarantees correct installation and effective waterproofing. Furthermore, professionals have access to top-quality materials and tools that homeowners may not readily have access to. They possess knowledge of which membrane type is appropriate for various applications and can recommend the best product based on individual needs. Additionally, professionals have access to specialized equipment, enabling more efficient and effective installation. In addition, professional installation offers the advantage of warranties and guarantees. Reputable waterproofing companies typically provide warranties for their services, providing homeowners with peace of mind. They can trust that any issues that arise will be addressed and resolved by the professionals. Lastly, waterproofing is essential for safeguarding homes against water damage and maintaining structural integrity. Improper installation or a faulty membrane can lead to water leaks, mold growth, and expensive repairs. By hiring a professional, homeowners can be confident that the waterproofing membrane will be installed correctly, reducing the risk of future problems. In conclusion, while it is possible for homeowners to install waterproofing membranes themselves, the complexities of the process and the advantages of professional installation make it highly recommended to hire a professional for this task. Their expertise, access to quality materials, warranties, and guarantees provide homeowners with the reassurance that the job will be carried out correctly and effectively, ultimately protecting their homes from water damage.

- Q: Does a waterproofing membrane require a protective layer?

- Yes, a waterproofing membrane typically requires a protective layer. The protective layer serves multiple purposes. Firstly, it helps to prevent damage to the waterproofing membrane during and after installation. It acts as a barrier against sharp objects, construction debris, and potential punctures. Additionally, the protective layer helps to distribute loads evenly and provide stability to the membrane, reducing the risk of damage caused by foot traffic or heavy equipment. Furthermore, the protective layer serves as a UV barrier, shielding the waterproofing membrane from the harmful effects of sunlight exposure. UV rays can degrade the membrane over time, leading to reduced effectiveness and potential leaks. The protective layer also helps to regulate temperature fluctuations, which can expand and contract the membrane, causing stress and compromising its waterproofing capabilities. In summary, a protective layer is essential for the longevity and performance of a waterproofing membrane. It safeguards against physical damage, UV radiation, and temperature fluctuations, ensuring the membrane's effectiveness in keeping water out and preserving the integrity of the structure it protects.

- Q: Does a waterproofing membrane have any fire resistance properties?

- No, a waterproofing membrane typically does not have any fire resistance properties. The main purpose of a waterproofing membrane is to provide a barrier against water infiltration and protect the underlying structure from moisture damage. Fire resistance, on the other hand, refers to a material's ability to withstand fire or reduce the spread of flames. Fire resistance properties are typically found in specialized fireproofing materials or coatings, which are designed to prevent the spread of fire and protect the structure in case of a fire incident. It is important to consider both fire resistance and waterproofing requirements when selecting materials for construction projects, as they serve different purposes and may require separate measures to ensure safety.

- Q: Can a waterproofing membrane be used for swimming pools?

- Certainly, swimming pools can utilize a waterproofing membrane. These membranes are specifically designed to hinder water infiltration and can be applied to various surfaces, including concrete, to establish a completely impermeable seal. This is especially crucial for swimming pools, as they are continuously exposed to water and necessitate a dependable waterproofing system to avert leaks and water-related harm. The waterproofing membrane acts as a safeguarding barrier, guaranteeing that the pool retains its watertightness and preventing any water from seeping into the nearby structures. Furthermore, waterproofing membranes also offer resistance against chemicals, UV rays, and other environmental factors, effectively fortifying the swimming pool's durability and longevity.

- Q: Can a waterproofing membrane be used on vinyl surfaces?

- Indeed, one can employ a waterproofing membrane on vinyl surfaces. Vinyl surfaces, including vinyl flooring or vinyl siding, are frequently encountered in both residential and commercial structures. Waterproofing membranes are specifically crafted to establish a barrier against water and moisture, effectively hindering their infiltration into the underlying materials. By applying such membranes onto vinyl surfaces, an extra layer of safeguarding is provided, thereby guaranteeing that the vinyl remains unharmed by water-related issues or decay. Selecting a waterproofing membrane that is compatible with vinyl surfaces is crucial, as is adhering to the manufacturer's instructions for correct application.

Send your message to us

Black EPDM Rubber Waterproofing Membrane applt to Bridge/Road

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords