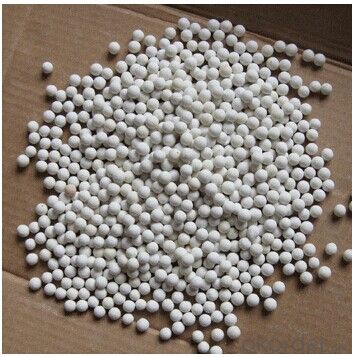

Bio Ceramic Ball Monolithic Refractories for Water Treatment in Iron and Steel Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Ingredients:

Tourmaline: 30%

Porcelain clay: 20%

High grade clay: 15-20%

Others: 30-35%

Main Features:

Amount of generating negative ions: 400500pc/s.cm3

Radiance of far infrared ray the wavelength is 225μm≥85%

PH of soaking water solution: 7.2-7.6

Insoluble, gradually releasing mineral substance

Instruction For Use:

Should wash with clean water for two times in the first, then can be directly used for treating drinking water. Keep from raining, and avoid moisture. Stored in dry place.

Note:

the highest using temperature is at 950

Description:

One kind of environmental protection and health care ball that is mainly made of the natural nonmetal mineral tourmaline, kaolin and high-grade clay by nanometer combination technology, special formula and agglomeration techniques, and used with the ceramic ball for activating, purifying and mineralizing drinking water.

Application :

For various types of water purifier, drinking water dispenser and water supply system and equipments, agriculture and industry, etc.

- Q: What are the main causes of monolithic refractory failure in the iron and steel industry?

- Monolithic refractory failure in the iron and steel industry can be attributed to various causes. Thermal cycling stands out as one of the primary factors. The extreme temperatures encountered during iron and steel manufacturing, including melting, casting, and heat treating, expose the refractory lining to significant thermal stress. This repetitive expansion and contraction of the material can lead to cracking, spalling, or even complete disintegration of the refractory. Chemical attack is another common cause of failure. The iron and steel industry utilizes different chemicals, such as molten metal, slag, and gases, which can react with the refractory lining. This chemical interaction can result in erosion, corrosion, or chemical decomposition of the refractory material, ultimately causing failure over time. Mechanical stress also plays a significant role in monolithic refractory failure. The heavy machinery and equipment employed in iron and steel production produce vibrations, shocks, and impacts that can weaken or damage the refractory lining. Additionally, improper installation or design can create stress concentration points, making the refractory more susceptible to failure. Furthermore, refractory failure can be attributed to improper maintenance and operational practices. Inadequate cooling or heating procedures, improper drying and curing of the refractory, and insufficient cleaning and inspection can all affect the longevity and performance of the material. Neglecting regular maintenance and timely repairs can exacerbate minor issues, eventually leading to more significant failures. Lastly, the choice and quality of refractory material are crucial factors in failure. Opting for an unsuitable refractory for a specific application or using low-quality materials can result in premature failure. Considering factors such as temperature range, chemical exposure, and mechanical stress is essential when selecting the refractory lining to ensure its suitability and durability in the iron and steel industry. To summarize, the main causes of monolithic refractory failure in the iron and steel industry include thermal cycling, chemical attack, mechanical stress, improper maintenance and operational practices, and the choice and quality of refractory material. Addressing these factors through proper installation, regular maintenance, and careful material selection can help mitigate refractory failures and enhance the overall efficiency and productivity of iron and steel production processes.

- Q: What are the challenges in recycling and disposing of monolithic refractories?

- In order to minimize the environmental impact and maximize resource efficiency, several challenges must be overcome when recycling and disposing of monolithic refractories. One significant challenge lies in the handling and transportation of these refractories due to their heavy and bulky nature. Since they are commonly used in high-temperature applications, dismantling and removing them from equipment can be difficult. The weight and size of monolithic refractories make transportation to recycling or disposal facilities a challenge, requiring specialized equipment and infrastructure. Another obstacle is the heterogeneity of monolithic refractories, which often contain various types of refractory materials, binders, and additives. This complexity makes it challenging to separate and categorize the different components for effective recycling. The lack of standardized recycling processes for monolithic refractories further complicates recycling efforts. Moreover, the high melting points of refractory materials used in monolithic refractories make conventional recycling methods, such as melting and remolding, energy-intensive and costly. It is necessary to explore and optimize alternative recycling methods like thermal treatment or chemical processing to make the recycling process more economically and environmentally viable. Proper disposal of monolithic refractories is also a challenge. If not recycled, these materials often end up in landfills, occupying valuable space and potentially releasing harmful substances into the environment. Landfilling refractories can also pose contamination risks if not managed correctly or if hazardous additives are present. To address these challenges, it is crucial to invest in research and development to create more efficient and cost-effective recycling technologies for monolithic refractories. Collaboration between manufacturers, recycling facilities, and regulatory bodies is also essential to establish guidelines and standards for recycling and disposal. Additionally, educating industries and end-users about the importance of recycling and the availability of recycling options can help increase the demand and feasibility of recycling monolithic refractories.

- Q: What are the key considerations when selecting monolithic refractories for tundish applications?

- When selecting monolithic refractories for tundish applications, the key considerations include thermal stability, erosion and corrosion resistance, thermal shock resistance, ease of installation and maintenance, and cost-effectiveness.

- Q: How do monolithic refractories improve the performance and efficiency of iron and steel production?

- Improved performance and efficiency in iron and steel production are achieved through the utilization of monolithic refractories. These specialized materials are designed to withstand extreme temperatures, chemical reactions, and mechanical stresses, making them ideal for high-temperature industrial processes. A key contribution of monolithic refractories is their ability to provide a protective lining for furnaces, kilns, and other equipment used in iron and steel production. Their superior heat resistance ensures that the underlying structure is shielded from the intense heat, preventing any detrimental effects on the equipment. This results in reduced downtime, extended service life, and ultimately, enhanced overall efficiency. Furthermore, monolithic refractories play a crucial role in improving thermal efficiency during the production process. By minimizing heat losses, these materials help maintain a stable and uniform temperature distribution, thereby enhancing the energy efficiency of the system. Precise temperature control is of utmost importance in iron and steel production to achieve the desired metallurgical properties of the final product. Additionally, monolithic refractories exhibit excellent resistance to chemical corrosion, erosion, and slag attacks. They act as a barrier between the molten metal and the refractory lining, preventing unwanted reactions and material degradation. This preserves the integrity of the furnace lining, reducing the need for frequent repairs or replacements. Consequently, it leads to increased productivity and long-term cost savings. Moreover, the ease with which monolithic refractories can be shaped, repaired, or replaced is another advantage. Unlike traditional brick refractories, which require labor-intensive and time-consuming installation, monolithic refractories offer a more flexible and efficient application. Their flexible nature allows for easy repair of damaged areas, minimizing downtime and ensuring uninterrupted production. In summary, the utilization of monolithic refractories significantly enhances the performance and efficiency of iron and steel production. These materials provide a protective lining, improve thermal efficiency, resist chemical corrosion, and offer easy installation and repair options. By optimizing the production process, monolithic refractories contribute to higher productivity, reduced downtime, and increased cost-effectiveness in the iron and steel industry.

- Q: What are monolithic refractories and how are they different from other refractory materials?

- Monolithic refractories are a type of refractory material that is produced and applied in a single, unified form. Unlike other refractory materials, such as bricks or tiles, monolithic refractories are not pre-formed into specific shapes or sizes. Instead, they are generally composed of a mix of aggregates, binders, and additives, which are then installed in place and cured to form a solid, dense structure. One key difference between monolithic refractories and other refractory materials is their versatility and ease of installation. Traditional refractory bricks or tiles require skilled labor and careful assembly to create a lining or structure. Monolithic refractories, on the other hand, can be poured, sprayed, or gunned into place, allowing for a much faster and more efficient installation process. This makes them particularly suitable for complex shapes or areas that are difficult to access. Another difference lies in the physical properties of monolithic refractories. While bricks and tiles are typically characterized by their high mechanical strength and resistance to thermal shock, monolithic refractories can be tailored to exhibit a wide range of properties. They can be engineered to have excellent thermal insulation, superior corrosion resistance, or enhanced abrasion resistance, depending on the specific application requirements. This flexibility makes monolithic refractories suitable for a variety of industries, including steel, cement, glass, and petrochemical. Furthermore, monolithic refractories have the advantage of being able to expand and contract with temperature changes, unlike rigid brick structures. This thermal flexibility helps to minimize cracking and damage caused by thermal cycling, prolonging the lifespan of the refractory lining. Additionally, monolithic refractories offer better refractory integrity and reduced joint failure, as there are no seams or weak points that can be susceptible to thermal stresses. In summary, monolithic refractories are a versatile and convenient type of refractory material that can be customized to meet specific application requirements. Their ease of installation, thermal flexibility, and tailor-made properties make them distinct from other refractory materials such as bricks or tiles.

- Q: How do monolithic refractories contribute to the reduction of emissions in iron and steel plants?

- Monolithic refractories play a crucial role in reducing emissions in iron and steel plants by providing various benefits and solutions to the environmental challenges faced by these industries. Firstly, monolithic refractories are used to line the high-temperature zones of furnaces, such as blast furnaces and electric arc furnaces, that are integral to the iron and steel production processes. These refractories have excellent thermal insulation properties, which help to minimize heat loss and improve energy efficiency. By reducing heat loss, less fuel is required to maintain the desired temperature, resulting in lower energy consumption and subsequently lower emissions. Furthermore, monolithic refractories also contribute to emissions reduction by enhancing the combustion process. They are designed to resist thermal shock and withstand extreme temperatures, ensuring that the furnaces operate at optimal conditions. This, in turn, leads to more efficient combustion of fuels and raw materials, reducing the release of harmful gases and pollutants into the atmosphere. In addition to their thermal properties, monolithic refractories also possess excellent resistance to chemical attacks and corrosion. This is particularly important in iron and steel plants, where aggressive substances such as molten metal, slag, and gases are present. By providing a protective lining, these refractories prevent the degradation of furnace walls and other equipment, reducing the risk of leaks and emissions. Moreover, monolithic refractories are often used in the construction of pollution control devices, such as flue gas desulfurization systems and baghouses. These systems are designed to capture and remove pollutants from the flue gases generated during iron and steel production. The use of refractories in these applications ensures the durability and longevity of these systems, allowing them to operate efficiently and effectively in reducing emissions. Overall, monolithic refractories contribute significantly to emissions reduction in iron and steel plants through improved energy efficiency, enhanced combustion, corrosion resistance, and support for pollution control systems. By implementing these refractories, the industry can minimize its environmental footprint and move towards more sustainable and responsible production processes.

- Q: Can monolithic refractories be used for the lining of reheating furnaces and walking beam furnaces?

- Yes, monolithic refractories can be used for the lining of reheating furnaces and walking beam furnaces. Monolithic refractories are versatile and can be shaped to fit the specific requirements of these furnaces. They offer excellent thermal insulation, high temperature resistance, and durability, making them suitable for withstanding the extreme conditions within these furnaces. Additionally, monolithic refractories can be easily installed, repaired, and replaced, making them a practical choice for lining these types of furnaces.

- Q: How are monolithic refractories installed and repaired in iron and steel production facilities?

- Monolithic refractories are vital components in iron and steel production facilities, as they provide insulation and protection against high temperatures, chemical corrosion, and mechanical wear. The installation and repair processes for monolithic refractories in these facilities require careful planning, expertise, and adherence to safety protocols. When installing monolithic refractories, the first step is to prepare the surface by removing any loose material and cleaning the area thoroughly. This ensures proper adhesion of the refractory material. The surface may also need to be roughened or textured to improve bonding. Next, the monolithic refractory material is mixed with water or a binder to create a workable consistency. It is then applied to the prepared surface using various methods such as casting, gunning, ramming, or troweling. The choice of application method depends on factors such as the type of refractory material, the area being repaired, and the desired outcome. During installation, it is essential to carefully follow the manufacturer's instructions regarding mixing ratios, curing times, and drying temperatures. Improper installation can lead to reduced refractory performance, premature failure, and safety hazards. Repairing monolithic refractories in iron and steel production facilities is an ongoing process due to the harsh operating conditions and mechanical stresses they endure. When a refractory lining shows signs of damage or wear, it is crucial to address the issue promptly to prevent further deterioration. The first step in repairing monolithic refractories is to assess the extent of the damage. This can be done through visual inspection, thermal imaging, or non-destructive testing techniques. Once the damage is identified, the repair method can be determined. Minor repairs can often be carried out using patching materials. These materials are typically the same or similar to the original refractory composition and are mixed with water or a binder to form a paste. The paste is then applied to the damaged area and allowed to cure. For more extensive repairs, the damaged refractory material may need to be removed entirely. This can be done through mechanical methods such as chipping, grinding, or cutting. After the damaged material is removed, the surface is prepared as mentioned earlier, and new refractory material is installed using the appropriate application method. It is important to note that the repair process should be conducted by trained personnel with expertise in refractory installation and repair. Safety precautions such as wearing protective clothing, using proper tools, and following established procedures should always be observed. In conclusion, the installation and repair of monolithic refractories in iron and steel production facilities require careful planning, adherence to manufacturer's instructions, and expertise in refractory materials. By following proper procedures and promptly addressing any damage, these facilities can ensure the longevity and efficiency of their refractory linings, ultimately contributing to the smooth operation of their production processes.

- Q: How do monolithic refractories resist corrosion and erosion in the iron and steel industry?

- Monolithic refractories in the iron and steel industry are designed to resist corrosion and erosion through a combination of their composition and application techniques. Firstly, the composition of monolithic refractories includes high-quality raw materials such as alumina, magnesia, and silica. These materials possess excellent resistance to corrosion and erosion. Alumina, for example, is highly resistant to chemical attack and can withstand high temperatures, making it ideal for protecting against the corrosive nature of the iron and steel industry. In addition to the choice of materials, the application techniques used in installing monolithic refractories also play a crucial role in their resistance to corrosion and erosion. Monolithic refractories are typically installed using various methods such as gunning, ramming, or casting. These techniques ensure a tight and seamless bond between the refractory and the steel structure, minimizing the chances of corrosion and erosion. Furthermore, monolithic refractories can be customized to suit the specific needs of different parts of the iron and steel industry. For example, areas exposed to molten metal require refractories with high thermal conductivity and excellent resistance to chemical attack. By tailoring the refractory to the specific application, it becomes more effective in resisting corrosion and erosion. Moreover, monolithic refractories are often designed with additives or binders that enhance their resistance to corrosion and erosion. These additives can provide additional protection against chemical attacks from molten metal or corrosive gases, making the refractory even more durable in harsh conditions. Overall, monolithic refractories resist corrosion and erosion in the iron and steel industry due to their composition, application techniques, customization, and the inclusion of additives. By combining these factors, monolithic refractories provide excellent protection to the steel structures, ensuring their longevity and efficiency in the challenging environments of the iron and steel industry.

- Q: What are the factors affecting the lifespan of monolithic refractories?

- The lifespan of monolithic refractories can be significantly affected by several factors. 1. Operating temperature is a critical factor. While monolithic refractories are designed to withstand high temperatures, prolonged exposure to extreme temperatures can cause thermal shock and lead to premature failure. 2. Thermal cycling, which refers to frequent temperature fluctuations, can also shorten the lifespan of monolithic refractories. The refractory material expands and contracts, creating stress that can result in cracking and degradation over time. 3. The chemical environment where the monolithic refractories are used plays a crucial role in their lifespan. Exposure to corrosive gases, acids, alkalis, or molten metals can cause chemical reactions that degrade the refractory material. 4. Mechanical stress, such as abrasion, impact, and vibration, can weaken monolithic refractories and reduce their lifespan. This is particularly important in industries with high mechanical activity, such as steelmaking or cement production. 5. Proper installation and regular maintenance are essential for maximizing the lifespan of monolithic refractories. Inadequate installation techniques or neglecting maintenance can result in weak joints, inadequate anchoring, or the growth of cracks, leading to premature failure. 6. The quality and composition of the monolithic refractory material greatly impact its lifespan. Higher-quality materials with better resistance to temperature, chemical attacks, and mechanical stress tend to have longer lifespans. 7. The design of the refractory lining and its engineering considerations, such as thickness, shape, and reinforcement, also influence the lifespan of monolithic refractories. A proper design can distribute stress more evenly, reduce thermal gradients, and improve overall performance and durability. 8. The way monolithic refractories are operated and handled can affect their lifespan. Factors such as rapid temperature changes, improper cooling or heating procedures, or excessive thermal cycling can all contribute to premature failure. In conclusion, various factors such as temperature, thermal cycling, chemical environment, mechanical stress, installation and maintenance practices, quality of refractory material, design and engineering considerations, and operating conditions all impact the lifespan of monolithic refractories. Proper management and consideration of these factors are essential for maximizing their lifespan.

Send your message to us

Bio Ceramic Ball Monolithic Refractories for Water Treatment in Iron and Steel Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords