Better Quality Pre-Painted Galvanized/Aluzinc Steel Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

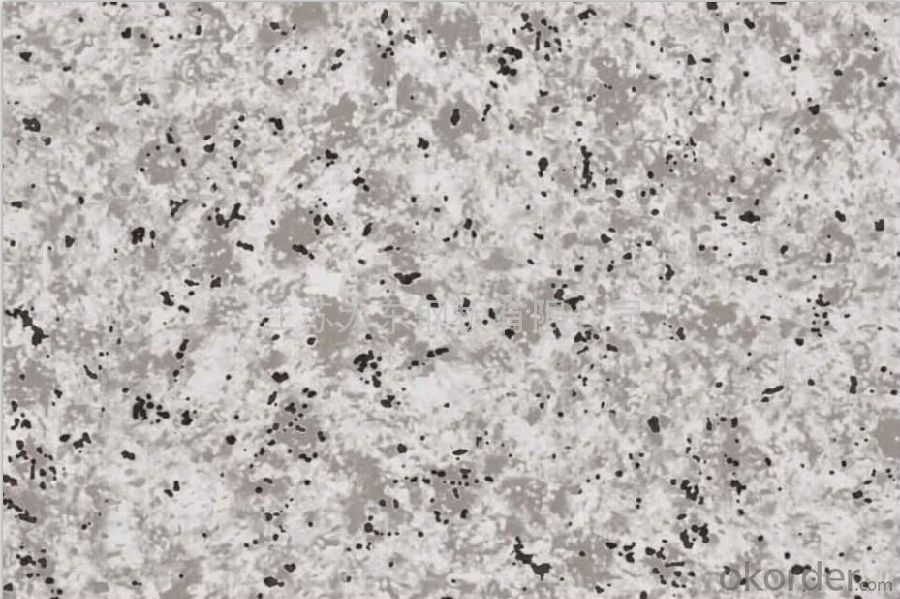

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the common applications of cold-rolled steel coils?

- Cold-rolled steel coils are commonly used in various applications such as automotive components, appliances, construction materials, and general manufacturing.

- Q: What are steel coils used for?

- Steel coils are used in a wide range of industries and applications, including manufacturing, construction, automotive, and appliances. They are commonly used in the production of various metal products such as pipes, tubes, sheets, and wires. Steel coils provide strength, durability, and versatility, making them essential in many industrial processes.

- Q: What is the thickness of a steel coil?

- The thickness of a steel coil can vary depending on the specific requirements and application. Typically, the thickness of a steel coil can range from a few millimeters to several centimeters.

- Q: What are the key factors affecting the strength of a steel coil?

- The key factors affecting the strength of a steel coil are the composition of the steel, the heat treatment process, the rolling and cooling processes, and the presence of any impurities or defects in the coil.

- Q: could anybody tell me the the weight of a cubic metre of mild steel? and where to get this info from?

- Weight per meter kg/m kg/m = (Oc - 4Wt) * Wt * 0.00785 Oc = outside circuit, Wt = wall thickness For sq. steel tubes: Oc = 4*a For rect. steel tubes: Oc = 2a + 2b Specific Weight =7.85 g/cm3

- Q: What are the different types of steel coatings for coils?

- There are several different types of steel coatings available for coils, each offering unique properties and benefits. Some of the most common types include: 1. Galvanized Coating: This is the most widely used type of steel coating for coils. Galvanized steel is coated with a layer of zinc, which provides excellent corrosion resistance and protection against rust. It is ideal for outdoor applications or environments with high moisture levels. 2. Galvannealed Coating: Galvannealed steel is a type of galvanized coating that undergoes additional heat treatment, resulting in a matte finish and improved paint adhesion. It offers enhanced corrosion resistance and is often used in automotive and construction industries. 3. Aluminized Coating: Aluminized steel is coated with a layer of aluminum, which provides excellent heat resistance and corrosion protection. It is commonly used in exhaust systems and other high-temperature applications. 4. Organic Coatings: Organic coatings, such as paint or powder coatings, can be applied to steel coils to provide additional protection against corrosion, as well as aesthetic appeal. These coatings come in a wide range of colors and can be customized to meet specific requirements. 5. Tin Coating: Tin-plated steel coils are coated with a layer of tin, which offers excellent solderability and corrosion resistance. It is commonly used in the manufacturing of cans and other food packaging materials. 6. Phosphate Coating: Phosphate coatings are typically applied as a pre-treatment before other coatings to improve adhesion and corrosion resistance. They create a thin, crystalline layer on the steel surface, promoting better paint or powder coating adhesion. These are just a few examples of the different types of steel coatings available for coils. The choice of coating will depend on the specific application requirements, considering factors such as corrosion resistance, heat resistance, paint adhesion, and aesthetic considerations.

- Q: Also, what is the top best slow cooker that is 100% stainless steel? Thank you!

- You do not want 100% stainless steel cookware, because it's a poor conductor of heat. All high quality stainless cookware is layered with stainless steel only on the exterior and interior surfaces, while having at least an internal heat spreading core of aluminum or copper. Not all stainless steel is sufficiently ferrous (magnetic) to work with electric inductive cooktops, so some stainless cookware adds an additional layer of ferrous steel in addition to the thermal cores. You also wouldn't want a slow cooker that's 100% stainless steel, because the uneven heating would cause food to burn more quickly. They are usually made of ceramic stoneware for a reason, even heating. Besides, a stainless pressure cooker (with alum/copper) core can in less than an hour everything a slow cooker does in 3+ hours, with better flavor, color, and nutritional content. By the way, the Prestige stainless cookware isn't 100% stainless, of course, and that's a GOOD thing.

- Q: Have spent two days making a specialized knife out of 304 stainless steel, after throwing into a log it bent slightly arghhhh. Is it worth continuing to finish it off or start all over again with different kind of steel if so which kind should i use.

- just because something is made out of 304 stainless steel does not make it tougher than carbon steel. Stainless steel includes other elements such as chromium. 304 stainless cannot be hardened by heat treatment.

- Q: I want to hear from those who own a scandium revolver. I know that scandium makes for a much lighter gun than steel, but how do they hold up durability-wise? Is their lifespan shorter than a comparable steel revolver?

- Not that I have ever heard. I have a pd340 thats about 3 yrs old, has about a thousand .38 rounds through it with no noticable loosening of the crane or anything. FWIW, the weight savings in a J frame is only a few ounces over an airweight, but the cost is almost double. Check out the SW 638 or 438.

- Q: How do steel coils contribute to earthquake resistance in structures?

- Steel coils contribute to earthquake resistance in structures by providing strength and flexibility. When incorporated into the structural design, steel coils can absorb and dissipate the energy generated during an earthquake, reducing the impact on the building. This helps prevent the structure from collapsing or suffering major damage. Additionally, steel coils enhance the overall stability and rigidity of the building, making it more resistant to seismic forces.

Send your message to us

Better Quality Pre-Painted Galvanized/Aluzinc Steel Roll

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords