Raw Materials for Refractory - Best Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Best Calcined Bauxite for Refractory Raw Materials

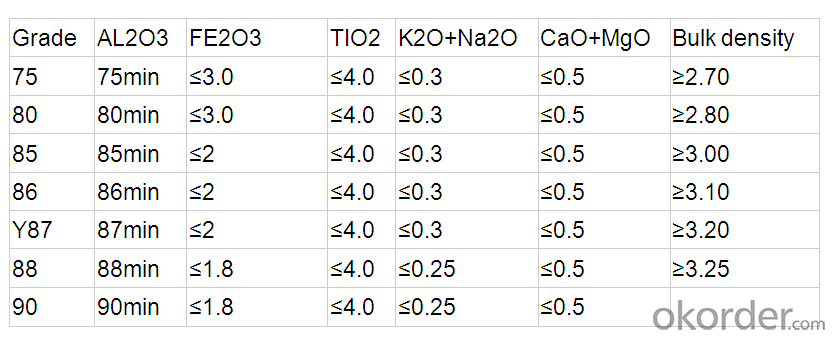

Specifications

1,Manufacturer-Direct sale

2,Good fireproof insulation

3,High bulk density

Our Advantages;

1. We have substantial experience for material manufacture and export.

2. We establish a long-term relation of cooperation with raw material supplier, so we can offer you the best quality and price.

3. We have equipped 8 production lines and skilled workers to make the quality best.

4. We can control strictly quality at factory and third party testing institutions quality inspection.

5. We can also offer you the related test report, both at factory and the third party testing institutions.

6. We have sufficient manufacturing capability to deliver the goods safely and timely.

7. We can pack in 25kg bags, 1mt big bags, 1.25mt big bags or as your request. We can also pack with pallet.

8. We have professional service team keep customers informed from delivery to discharge.

Product Description:

Usage

(1) aluminium industry. Used in national defense, aerospace, automotive, electronics, chemical industry,

daily necessities, etc.

2 precision casting. Alumina clinker made after the mould precision casting processed into fine powder.

Used in military industry, aerospace, communications, instrumentation, machinery and medical equipment department.

(3) is used for refractory products. High bauxite clinker refractoriness is as high as 1780, chemical stability strong,

and good physical properties.

Packaging & Delivery

Packaging Details: In bulk or in 1-1.25mr bag

Product Pictures:

If you’ve kind enquiries, please don’t hesitate to let us know. ^_^

- Q: How to divide the materials according to the National Fireproofing Material Standard?

- according to China's national standard GB8624-97, the combustion performance of construction materials can be divided into several classes: Class A: Incombustible building material: Almost no burning material. Class B1: nonflammable building material: nonflammable material has a good flame resistance effect. when it meet the open fire in the air or burnd at high temperature, it is difficult to spread quickly, and when the fire source is removed, the combustion stop immediately. Class B2: flammable building material: flammable material has a good flame resistance effect. when it meets open fire in the air or at high temperature, it will immediately burst into flames and easily cause fire spread, such as wooden column, timber roof truss, timber beam, and wooden stairs,ect.. Class B3: inflammable building material: No flame resisting effects, highly flammable, high fire risk.

- Q: How to calculate the thickness of choosing refractory? Such as steel ladle should choose what kind of refractory and using what thicknes?

- The relative production is lower and material cost is higher, the lining of the refractory is thicker: 1, determine the weight of the refractory material according to the main structure of the bearing capacity, to prevent damage to equipment, fire-proof material damage after the surplus size and thickness of the thermal conductivity of refractory materials, the smaller the effective volume, production output, the cost of materials) to consider the selection of refractory material thickness. 3 from the point of usage (usage cycle, relative usage cycle is longer, because under the condition of invariable in the device's overall dimensions of the refractory lining thickness to determine several basic principles, according to the volume of the weight computation of refractories and refractory thickness, these items must be fully consider the pros and cons before decided. 2 according to maximum temperature that shell can withstand.

- Q: What are the materials for refractory materials? What are their names?

- High temperature oxide materials in refractory special applications, such as aluminum oxide, lanthanum oxide, beryllium oxide, calcium oxide, zirconium oxide, refractory compounds, such as carbides, nitrides, borides, silicides and sulfides; high temperature composite materials, including metal ceramics, high temperature inorganic coatings and fiber reinforced ceramics.

- Q: Where is refractory used? Thank you!

- According to its refractoriness, it can be divided into ordinary refractory (1,580℃ to 1,770℃), high class refractory (1,770℃ to 2,000) and super refractory (above 2,000℃); according to chemical property, it can be divided into acid , neutral and alkali refractories, and including refractory used for special occasion. The current definition of refractory do not only depend on whether the refractoriness is above 1,580℃. At present, refractory is widely used as inorganic nonmetallic material of production equipment lining in metallurgy, petrifaction, cement, ceramics, power, etc. Refractory generally has good thermal shock resistance, chemical attack resistance, low thermal conductivity and coefficient of expansion, widely used in chemical, construction material, mechanical manufacturing, and ceramics, accounting for 50% to 60% in the total output. It can resist high-temperature action. Refractory has many varieties. Refractory materials are widely used in metallurgy; chemical properties divided by acidic refractories. In addition, cement, silicates. Refractoriness refers to that when cones sample made from refractory has no load. Currently, refractory refers to that is widely used in metallurgy, including neutral refractory and basic refractory.

- Q: Where is the sizing nozzle for refractories? Just enter the line, master into!

- Hua Heng refractories in the industry reputation is good, especially in the Southern small steel sales are among the best!

- Q: What are included in fireproofing materials?

- Incombustible?material of construction fire-proof material Grade A: Cement, stone, steel, coat, glass, aluminium alloy, ceramic tile, etc.; nonflammable material Grade B1: Fireproof?panel, rock wool.

- Q: Who knows about the grade C fireproof door materials?

- grade C fireproof door materials: 1. the doorframe raw materials of grade C fireproof doors: the galvanized?steel?sheet is no less than 1.2 mm(the thickness of steel plate is no less than 1.5 mm when the height and width of doors are more than 2.1 m and 1.2 m respectively). 2. the door leaf raw materials of grade C fireproof doors: the thickness of galvanized?steel?sheets is no less than 0.8 mm. 3. the reinforcement raw materials of grade C fireproof doors: the thick?steel?plate is no less than 1.2 mm, if there are bolt-holes, the thickness of which is no less than 3.0 mm. 4. filler: The fireproofing filling materials that fit the environmental and standard needs(for instance, door leafs are filled with perlite fireproof materials inside, and doorframes are filled with fire-resistant cement) meet the test criterion promulgated by the relevant state departments. 5, the sealing requirements: there are seal grooves in doorframes and within which are embedded with refractories.

- Q: Which fire-resistant materials have good viscidity?

- The viscidity of fire-resistant materials is also known as the binding performance of fire-resistant materials. It can be divided into chamotte and chemical binder. Both can work at normal or high temperature. The most commonly used chamotte are soft clay and aluminate cement. The commonly used chemical binders include sodium silicate, phosphoric acid, aluminum sulphate, aluminium phosphate, phenolic resin, etc. Fire resistant material is a complicated and overloaded system and we cannot know its materials and chemical components from the name alone. Both gunning mix and repair mix contain binder components. If they can used after adding water, then they may contain clay or fire resistan aluminum silicate cement.

- Q: whether the aluminum silicate thermal insulation material is fireproof or not?

- aluminum silicate is fireproof, and the melting point is between -40 ~ 800 ℃. Aluminum: it takes the flint clay clinker as raw material, produced by resistance or electric arc furnace fusion and injection fiber-forming process. its characteristics: Low thermal conductivity, excellent thermal and chemical stability, without binder and corrosive material.

- Q: How to distinguish the fire resistant level of construction materials?

- Division of fire resistant level of building material: 1, It can be divided into five levels according to the importance: a, special class: commerative, historic, international and national buildings. b, Class A: high-grade residential architecture and public building. c, class B: middle-grade residential architecture and public building. d, class C: orinary residential architecture and public building. 2, It can be divided into four grades according to fireproof?performance: Fire resistance level buildings is divided into four levels. Standard of fire resistant level is based on the combustion performance and fire endurance of main components of the house. 3, It can be divided into 4 levels according to durable life: a, A grade durable life, over 100 years, for important buildings and high-rise buildings. b, second level durable life, from 50 to 100 years, for ordinary buildings. c, third level durable life, from 25 to 50 years, for secondary buildings. D, fourth level durable life, less than15 years , for temporary buildings. I hope my answers will help you.

Send your message to us

Raw Materials for Refractory - Best Calcined Bauxite

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords