Bending Aluminum Sheets - Aluminum Sheet Thickness in All Kinds Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

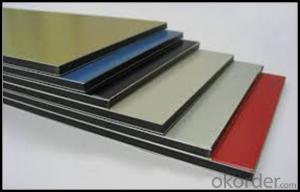

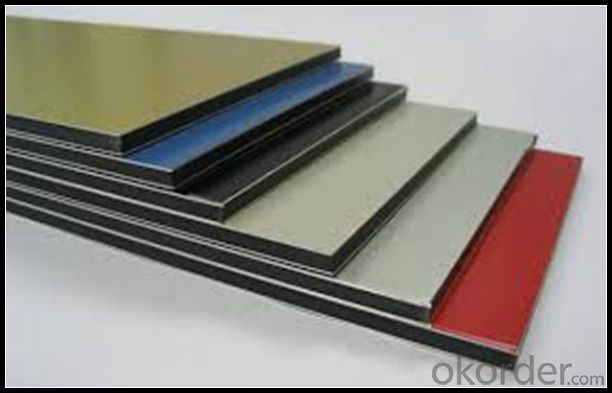

1.Structure of Aluminum Sheet Thickness in All Kinds Supply

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminum Sheet Thickness in All Kinds Supply

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

3. Aluminum Sheet Thickness in All Kinds Supply Images

4.Specification of Painted Aluminum Sheet for Composite Panels

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Which is better, a water bottle made out of steel or one made out of aluminum?

- Unless okorder / A lightweight Nalgene BPA free water bottle

- Q: How is aluminum sheet made?

- Aluminum sheet is made through a process called rolling, where a large aluminum ingot is passed through a series of rollers that gradually reduce the thickness of the metal until it reaches the desired sheet thickness. This process helps to improve the strength, flexibility, and surface finish of the aluminum sheet.

- Q: The only materials i can use is iodine, water, HCl, magnet, and pH paper. How do you identify aluminum with that?

- To start with, are you refering to aluminum as metal, an aluminum compound, or a solution with aluminum present as ions? If it is metaallic aluminum, it won't stick to a magnet, and it will react with HCl, however this isn't sufficient to definately say it is aluminum, it would be better to get a density, melting point, etc.

- Q: Can aluminum sheets be used for battery enclosures?

- Indeed, battery enclosures can utilize aluminum sheets. Aluminum proves to be a highly favored material for battery enclosures owing to its remarkable properties. Its lightweight nature, resistance to corrosion, and commendable conductivity render it an appropriate choice for safeguarding batteries and guaranteeing their optimal functionality. Furthermore, the exceptional strength-to-weight ratio of aluminum permits the creation of robust yet lightweight enclosures, making it an ideal selection for diverse battery applications. Moreover, the recyclability of aluminum adds to its appeal as an eco-friendly alternative. In conclusion, aluminum sheets serve as a feasible and frequently employed material for battery enclosures.

- Q: Aluminium magnesium alloy plate, 5052 aluminium plate, 5005 aluminium plate. 5252 aluminum plate performance and use

- Electronic cabinet material and LED LCD TV backlight board

- Q: Can aluminum sheet be used for heat sinks?

- Indeed, heat sinks can utilize aluminum sheet as a viable option. Aluminum, known for its commendable thermal conductivity attributes, is frequently employed as a material for heat sinks. Its lightweight nature, cost-effectiveness, and resistance to corrosion contribute to its popularity. With the ability to easily mold aluminum sheet into diverse shapes and sizes, it becomes suitable for a range of heat sink designs. The flat and thin composition of aluminum sheet aids in effective heat dissipation by expanding the available surface area for heat transfer. Moreover, aluminum can be readily machined or extruded to produce fins, further enhancing the heat dissipation capabilities of the heat sink. Overall, due to its myriad advantages, aluminum sheet stands as a favored choice for heat sinks in a multitude of applications, encompassing electronics, computers, LED lights, and automotive components.

- Q: Can aluminum sheets be perforated for decorative or functional purposes?

- Yes, aluminum sheets can be perforated for both decorative and functional purposes. Perforating aluminum sheets involves creating a pattern of holes or perforations in the metal surface. These perforations can serve various purposes depending on the specific application. For decorative purposes, perforated aluminum sheets are commonly used in architecture and interior design. The patterns of holes can add visual interest and create unique designs, allowing for the play of light and shadow. It can be used for decorative screens, partitions, facades, and ceiling panels, among other applications. Perforated aluminum sheets offer versatility in design, as different hole sizes, shapes, and arrangements can be used to achieve the desired aesthetic effect. In terms of functional purposes, perforated aluminum sheets provide several advantages. Firstly, they can improve airflow and ventilation in applications such as HVAC systems, air-conditioning units, and speaker grilles. The perforations allow air to pass through while still maintaining the structural integrity of the sheet. Secondly, perforated aluminum sheets can be used for sound absorption and noise reduction. The holes in the sheet disrupt sound waves, reducing noise levels in areas such as auditoriums, concert halls, and industrial facilities. Additionally, perforated aluminum sheets have practical applications in filtration and separation processes. They can be used as screens or sieves to separate particles of different sizes, allowing for the filtration of liquids or gases. These sheets are also used in the manufacturing of various industrial equipment, such as vibrating screens, grain dryers, and centrifuges. In summary, aluminum sheets can indeed be perforated for both decorative and functional purposes. Whether it is to enhance the visual appeal of a space, improve airflow, reduce noise levels, or aid in filtration processes, perforated aluminum sheets offer a versatile solution for a wide range of applications.

- Q: This question asks whether it is possible to utilize stamped or embossed aluminum sheets for a specific project.

- <p>Yes, you can use stamped or embossed aluminum sheets in your project. These sheets are known for their strength, durability, and lightweight properties, making them ideal for various applications such as construction, automotive, and aerospace. Stamped aluminum sheets are formed by pressing the material into a specific shape, while embossed sheets have a raised pattern. Both types offer design flexibility and can be customized to meet specific project requirements. Ensure that the aluminum sheets you select meet the necessary specifications for your project, such as thickness, strength, and finish.</p>

- Q: This question asks for methods to prevent rusting on aluminum sheets while they are being stored or transported.

- <p>To prevent rusting on aluminum sheets during storage and transportation, follow these steps: Store the sheets in a dry, cool environment away from moisture and humidity. Use protective coverings such as plastic wraps or sheets to shield them from dust and water. Avoid stacking them directly on the ground; use pallets or racks to keep them elevated. Regularly inspect the sheets for any signs of moisture or damage. If possible, apply a protective coating or sealant specifically designed for aluminum to create a barrier against corrosion. Proper handling and packaging can also reduce the risk of scratches or dents that could lead to rust.</p>

- Q: Can 101 aluminum sheets be used in food storage containers?

- Using 101 aluminum sheets in food storage containers is not recommended. These aluminum sheets, often referred to as 101 aluminum, are not suitable for storing food as they are not made from food-grade materials. Typically, they are employed in industrial settings like roofing, construction, and electrical wiring. To guarantee the safety and quality of stored food, it is essential to use containers crafted from food-grade materials such as stainless steel, glass, or food-grade plastic.

Send your message to us

Bending Aluminum Sheets - Aluminum Sheet Thickness in All Kinds Supply

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords