Beam - Tray Type Racking Shelving Systems

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Beam type pallet racking system has simple structure and reliable.

Goods for storage and carrying has no limits. It's usually used in pallet storage and forklift warehouse.

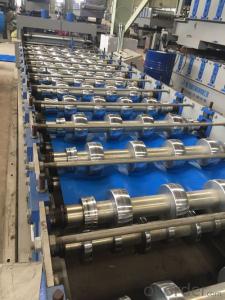

It consists of upright, beam, strut.It forms structure by C upright and weld beam. It has 75mm adjustment range.

Feature:

· Large loading weight

· Customized design

· Professinal service

Images:

Specification:

Loading weight | 5000KG/layer |

Height | 12 M customized |

FAQ:

What is note for purchase?

Pallet size,good weight, warehouse sapce and height, forklift details, etc.

How is quality guaranteed?

The production use professional roll forming technology and material of steel for production have strict test. The finished product into market are all guaranteed for users

How about the project installation?

Drawing for installation is provided for users. We also could send engineers to users's spot to carry out installation.

- Q: What are the key functions of warehouse management logistics informatization construction?

- In the warehouse management system, customer first is the initial inventory management (initial information collection), when the inventory is automatically increased after receipt when purchasing, sales, inventory system automatically reduced, and parity did not affect changes in the allocation of inventory, so inventory only through the inbound or outbound change or not change and, the administrator can query specific types of inventory. --- warehouse management, EBIG logistics, warehousing management system (WMS)

- Q: How to strengthen the integration and construction of logistics infrastructure

- All kinds of transport stations. Because according to a certain area and goods freight organization characteristics of planning and construction, this function cannot be simply used to replace with the supply chain organization of logistics organization, logistics organization is not equal to the freight organization, and can form a freight logistics organization in the process, but not all social goods. As a part of the cargo for the enterprise supply chain implementation in the space layout requirements of the organization according to the logistics, freight station has meet the service needs of the decentralized logistics organization function is a must, therefore, besides having the function of freight freight station node, need to upgrade or enrich its service function.

- Q: What are the irrational aspects of warehousing in logistics?

- Rapid logistics reaction. The logistics service provider on the upstream and downstream logistics and distribution demand response faster, shorter lead time, distribution interval is shorter and shorter, logistics faster, more and more commodity turnover.

- Q: What are the logistics facilities and equipment in the supermarket?

- Boutique shelves, display rack, rack, titanium alloy, titanium alloy, Variety shelves, racks, steel rack, storage rack, display rack, CD rack, Variety shelves, storage shelves, sample rack, display cabinets, cabinet boutique, boutique shelves.

- Q: The role of warehouse management in Enterprises

- Its functions and tasks are mainly:1, the use of market economy means to obtain the largest allocation of storage resources.2, the principle of high efficiency organization management.3, continue to meet the needs of the community as the principle of business activities.4, with high efficiency, low cost as the principle of organizing warehouse production.5, to high-quality services, credit, establish corporate image.6, through the institutionalization, scientific advanced means, and constantly improve the management level.7, from technical to spiritual areas to improve staff quality.

- Q: What are the storage facilities and equipment included?

- When the warehousing industry exists as a format, logistics is an effective means to realize value-added services, and warehousing is an indispensable node in the logistics industry.The development of modern logistics industry needs the support of modern warehouse management, and the advanced technology of informatization and the guidance of information technology has become an effective way for the warehousing industry to modernize.

- Q: What are the commonly used automation equipment in warehouse logistics?

- Such as the commonly used transport equipment, the car these

- Q: What is the warehousing logistics distribution center?

- The distribution center must first purchase the goods to be supplied and distributed in order to supply materials to its users, that is, manufacturing enterprises or commercial enterprises, in a timely and accurate manner. The distribution center shall formulate and adjust the unified and comprehensive purchasing plan according to the change of supply and demand in the market, and shall be organized and implemented by special personnel and departments.

- Q: What are the main facilities and equipment in the warehouse?

- Logistics warehousing equipment is divided into two major categories: logistics equipment, storage equipment.

- Q: What brands of operating equipment are used in the major logistics and express companies in China?

- Many express companies are designed for special companies. They include roller conveyors, electronic packages, sewing racks, sewing machines, wireless guns, trays and the like

Send your message to us

Beam - Tray Type Racking Shelving Systems

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords