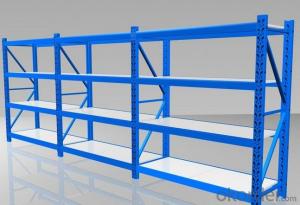

Beam Type Plate Racking System for warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Beam type pallet racking system has simple structure and reliable quality. It's suitable for big weight goods.

Goods for storage and carrying has no limits. It's usually used in pallet storage and forklift warehouse.

It consists of upright, beam, strut. It's formed structure by C upright and weld beam. It has 75mm adjustment range. Good technology is applied in its production and long working life.

Feature:

· Large loading

· Customized

· Professinal production

Images:

Specification:

Loading | 5000KG |

Height | 12 M |

FAQ:

What is note for purchase?

Manufactuering backgroud, technique, warehosue conditions, etc

How is quality guaranteed?

Material and craft is guarantted in its production.

How about the project installation?

Drawing for installation, engineers to users's spot to carry out installation.

- Q:How to do the warehouse logistics supervisor?

- Understand the type of storage, the amount of storage, the amount of work done, etc.. After understanding the warehouse function, we should clearly will be used for storage of goods warehouse properties, ordinary goods or special goods, in the control of temperature and humidity on whether there are specific requirements, if they need special anti-static turnover box and other special storage containers. If you do not understand, can go to such a comprehensive logistics Guanyu products supporting enterprises.

- Q:What are the main facilities and equipment in the warehouse?

- 1, a variety of specialized warehouses;2. Facilities in the warehouse;3, all kinds of ancillary equipment, such as: explosion protection, fire fighting, metering, temperature measurement, ventilation, information management, etc.

- Q:What are the responsibilities of the warehouse and logistics department?

- Material storage environment must be kept clean and beautiful. Make sure that the materials and facilities in the warehouse are free of dust, and there are no weeds around the cargo yard and the temporary cargo yard.The storage of the goods should be properly clean, strong safety, reasonable and complete, thatch pad material sign marks. Fixed location of storage of materials to implement the "four position" and "55 stack", and to comply with the quality system, environment / safety management system standards.Warehouse management of inventory must be in accordance with the "six check" content, check, check, check the number of quality measurement tools, storage method, check, check the safety check, serious circulation from the point, since the rate of not less than 50% months, or two months in the inventory of all materials to all at a time. The number of correct inventory requirements, consistent with accounts, no account materials, and make self recording.For materials that need temperature and humidity control, the storage procedures for special requirements must be strictly enforced, daily monitoring of temperature and humidity shall be carried out and records shall be duly made.

- Q:What are the logistics facilities and equipment in the supermarket?

- Supermarket trolleys, logistics and warehousing facilities; cage, hand basket, supermarket shopping cart, shopping cart, cart, logistics, vehicle logistics, tally, parity, plastic trolleys, shelves and logistics equipment, storage shelves, supermarket shelves, pallets, cashier, wood products, Vegetable & Fruit frame, truck, supermarket the supermarket shopping facilities, supporting facilities, electronic products, storage equipment, tool cart, flat cart, mobile station car, hanging plate rack, pallet stacker, forklift, hydraulic car, metal products, etc..

- Q:What are the types of logistics equipment?

- According to the equipment in the logistics activities in a considerable position, can be divided into fixed equipment and movable equipment. Fixed equipment such as railway, highway, bridge and tunnel; stations, ports, warehouses and other buildings I equipment such as train, cars, ships, mobile handling equipment.

- Q:How to carry out logistics warehousing operations?

- Whether we can allocate human resources and operate effectively is one of the most important criteria for efficient warehouse management.Artificial management technology can help those who are troubled employees warehousing enterprises, auxiliary management decision-making staff number storage required, and can adopt the labor standards and engineering support system to evaluate the performance of warehouse workers. In addition, companies should provide incentives for teams of employees, not individuals, to maximize the team's potential. There are many warehouse management systems lack of artificial management and performance evaluation considerations, or the lack of manual management of this function of convergence.

- Q:The difference between electricity supplier logistics and traditional logistics warehousing management

- (1) the traditional logistics is the storage area and the sorting area sharing, its essence is the few varieties, the massive quantity enters and sells pattern to decide. The facilities in the library are usually flat warehouse (stacking) and stereoscopic high shelf. Because of the characteristics of large quantities, the number of boxes to go in and out, and even to support as auxiliary units; storage and transfer of more pallets as the carrier.(2) logistics providers due to the characteristics of multi variety and small batch, at present by manual, it is necessary to use special storage area to improve storage utilization; improve the picking efficiency picking area (with special light shelf, a flat tray storage supplement. )

- Q:What is the warehousing logistics distribution center?

- The distribution center must first purchase the goods to be supplied and distributed in order to supply materials to its users, that is, manufacturing enterprises or commercial enterprises, in a timely and accurate manner. The distribution center shall formulate and adjust the unified and comprehensive purchasing plan according to the change of supply and demand in the market, and shall be organized and implemented by special personnel and departments.

- Q:Common equipment for warehouse logistics equipment

- Three dimensional shelf, conveyor equipment, AGV trolley, reciprocating lift, pallet, etc. 134313 dragon 67497 provide reference!

- Q:What aspects of logistics and warehousing management?

- Should meet the following requirements in the general layout of warehouse: (1) abide by the laws and regulations of various buildings and facilities planning; (2) to meet the requirements of warehouse operation smoothly, avoid repeated handling circuitous transportation; (3) ensure the storage of goods safety; (4) ensure the working safety; (5) the maximum use the warehouse area; (6) to make full use of warehouse facilities and equipment; (7) comply with the security and fire protection requirements; (8) consider warehouse expansion requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Beam Type Plate Racking System for warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords