Steel Platform Type Racking System for Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

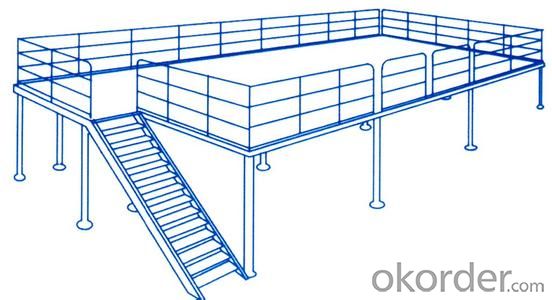

Steel platform, one kind of pallet racking system, also called attic shelf or multi layer racking system, which could be used in warehouse and logistic center.

It is suitable for limited space of warehouse and could have multi layers two or three.

The production adopts advanced roll forming technology and guarantee good quality and high precision. Good material ensure long usage life.

Feature:

· Ladder for upstair.

· Metal floor installed.

· Suitable for various goods.

· Frame supporting.

Images:

Specification:

Loading | 500KG |

Space | 3-5 m |

Height | design |

FAQ:

What is steel platform ?

Steel platform is used in factory for space usage, usually have 2-3 floors and have big loading capacity.

How is quality guaranteed?

Professional technology is used in its production and good material make sure of its long working life.

How about the project installation?

Drawing for installation is provided for users.

- Q: What are the logistics and warehousing equipment? The more, the better

- Plastic tray tray, wooden pallets, steel pallets, storage cage, tchouk frame, logistics trolley, forklift cage, shelves of light, medium, heavy.

- Q: What are the types of logistics equipment?

- According to the service scope of equipment in the logistics activities, it can be divided into enterprise (production), logistics equipment and social (supply and marketing) logistics equipment. Enterprise logistics equipment enterprise fixed assets is part of belonging to the enterprise of its own equipment, such as transport vehicles, the railway line, handling machinery, packaging machinery, storage and construction: social logistics equipment logistics services for the community, belong to utilities, such as transport routes, stations, ports, bridges and tunnels.

- Q: How to strengthen the integration and construction of logistics infrastructure

- Specialized facilities. Is the different links in the supply chain, in different places with support to the supply chain, supply chain management to meet the individual functional requirements, or to a single function, professional facilities with other auxiliary functions, the facilities are in accordance with their own needs and characteristics of the service object layout function setting, these facilities including a variety of modes of transport hubs and stations, storage facilities, etc..

- Q: What are the storage facilities and equipment included?

- When the warehousing industry exists as a format, logistics is an effective means to realize value-added services, and warehousing is an indispensable node in the logistics industry.The development of modern logistics industry needs the support of modern warehouse management, and the advanced technology of informatization and the guidance of information technology has become an effective way for the warehousing industry to modernize.

- Q: What are the problems in e-commerce, logistics and warehousing?

- At present, the application of information technology in logistics enterprises is not only relatively small, but also the application level is low, and the computer applications are limited to office automation and daily transaction processing. According to the China Association of warehousing survey, most of the logistics enterprises in 2002 still do not have the ability to use modern information technology to deal with logistics information. In the information system of logistics enterprises, business functions and system functions of the information system is not perfect, the lack of necessary order management, cargo tracking, warehouse management system and transportation management system of logistics service system, the ability to integrate the logistics information resource has not been formed. Moreover, in foreign countries, logistics enterprises have widely applied bar code technology, and RFID, GPS/GIS and EDI technology are not ideal for the application of Chinese logistics enterprises. In addition, most of the domestic logistics equipment is relatively old, including three-dimensional warehouse, bar code automatic identification system, automatic guided vehicle system, automatic cargo tracking system, including logistics automation facilities, not much. Compared with foreign logistics management automation with electromechanical integration and intelligent characteristics, the gap is great.

- Q: What is the warehousing logistics distribution center?

- The distribution center must first purchase the goods to be supplied and distributed in order to supply materials to its users, that is, manufacturing enterprises or commercial enterprises, in a timely and accurate manner. The distribution center shall formulate and adjust the unified and comprehensive purchasing plan according to the change of supply and demand in the market, and shall be organized and implemented by special personnel and departments.

- Q: The advantages and disadvantages of logistics line type I U type L

- The conceptual design, functional design and technical design are introduced briefly in three different design stages, and the design principle of "from the inside to outside" is adopted to maximize the space utilization and operation efficiency. This time, we will introduce several major design types of logistics centers, including I, L, and U. And before the introduction of different types of logistics center, the first to know when the definition of a logistics center belongs to U type, does not refer to the logistics center of the building appearance is U, but the logistics center's internal operation process was U type, especially the flow of goods. Below, we will briefly introduce the characteristics of different types of logistics centers.

- Q: Storage facilities and equipment is not perfect, what?

- In order to adapt to the rapid expansion of warehouse operation, storage industry needs to greatly improve automation. For example, we need to use more delivery to deliver small items over long distances while setting an appropriate number of repacking stations and loading and unloading platforms. In addition, if we use more automatic sorting equipment, we can improve the overall work capacity without building additional sites. As a result, automated equipment will continue to replace labor in operations such as cargo handling, which add little or no value.

- Q: What are the third party logistics? What are the advantages and disadvantages?

- 3PL can meet these requirements in a fast and cost effective way that is often difficult to achieve by manufacturers alone. Similarly, 3PL also has the ability to meet the potential customer needs of manufacturing firms, thereby contributing to the communication between producers and retailers.

- Q: What are logistics facilities and equipment?

- Logistics equipment is an important tool for the development of modern logistics industry. It plays a very important role in improving the ability and efficiency of logistics system, reducing logistics costs and ensuring the quality of logistics. Facility configuration Consulting provides comprehensive logistics facilities and equipment solutions to customers.

Send your message to us

Steel Platform Type Racking System for Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords