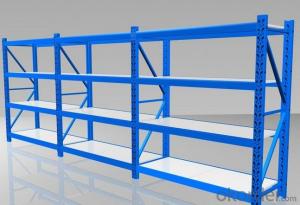

Heavy Duty Type Pallet Racking System for Warehouse

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Heavy duty pallet racking system is commonly used in manufacturing industry and logistics inductry, like logistic centre.

It's both suitable for samll goods and big goods, in large quantity or not. Heavy duty pallet rack is used in high warehouse and super high warehouse. Automatic warehouse also use this kind of racking system.

Feature:

· Customized design

· Big loading weight

· Professional service

Images:

Specifications:

Loading weight | 3000KG |

Height | 8-12M customized |

FAQ:

What is note for purchase?

Pallet size,good weight, warehouse sapce and height, etc.

How is quality guaranteed?

The production use professional roll forming technology and material of steel for production have strict test. The finished product into market are all guaranteed for users

How about the project installation?

Drawing for installation is provided for users. We also could send engineers to users's spot to carry out installation.

- Q:What are the commonly used facilities in the logistics industry?

- 1 filling machinery and equipment (propeller, propeller, vibration feeder, gravity conveying vacuum filling system with feeder, etc.) 2 filling machine (paste filling machine, sealing machine (3) hand pressing sealing machine, sealing machine, pedal type floor type automatic sealing machine, horizontal automatic sealing machine, automatic sealing machine, vertical ultrasonic sealing machine, semi automatic screw type sealing machine, wrapping machine (4) cantilever stretch film winding wrapping machine, pull seam wrapping machine etc.) 5 (automatic labeling machine of RG1001 type double labeling machine, this machine is less.)

- Q:What are the main facilities and equipment in the warehouse?

- 1, horizontal transport equipment, including a variety of vehicles, conveyor belts, belt machines, etc.;2, packaging equipment: including packaging, packaging machinery, yards, equipment and so on;3 、 vertical conveying equipment: hoist, forklift, stacker and so on;4, handling equipment: such as a large crane (gantry container cranes), ship unloading of various professional equipment (car);5 、 Safety Monitoring equipment;6 、 automatic management equipment.

- Q:Question: what is the nature of logistics warehousing?

- Productive logistics land generally includes the production enterprises directly used for material storage, transit, distribution, distribution, transportation, loading and unloading, as well as the corresponding ancillary facilities, and its nature can be identified as industrial storage land;

- Q:What are the logistics facilities and equipment in the supermarket?

- Supermarket trolleys, logistics and warehousing facilities; cage, hand basket, supermarket shopping cart, shopping cart, cart, logistics, vehicle logistics, tally, parity, plastic trolleys, shelves and logistics equipment, storage shelves, supermarket shelves, pallets, cashier, wood products, Vegetable & Fruit frame, truck, supermarket the supermarket shopping facilities, supporting facilities, electronic products, storage equipment, tool cart, flat cart, mobile station car, hanging plate rack, pallet stacker, forklift, hydraulic car, metal products, etc..

- Q:The role of warehouse management in Enterprises

- Warehouse management, that is, library management. Warehouse management refers to the warehouse and its inventory management, warehousing system is an indispensable subsystem of the enterprise logistics system. The overall objective of logistics system is to provide customers with satisfactory service at the lowest cost, while the warehouse system plays an important role in it. Storage activities can promote enterprises to improve customer service levels, and enhance the competitiveness of enterprises. Modern warehouse management has changed fundamentally from static management to dynamic management, and has put forward higher requirements for the basic work of warehouse management.

- Q:Storage facilities and equipment is not perfect, what?

- Increase the hardware input to the warehouse.This includes warehouse construction and renovation, purchase of new shelves, pallets, digital automatic identification system and sorting, processing, packaging and other logistics equipment, greatly enhance the level of automation of existing warehouse and logistics operation efficiency, increase the function of logistics services.

- Q:What is the warehouse keeper in the logistics industry?

- The job of the warehouse keeper in the logistics industry is probably:1, according to the provisions of good materials and equipment access library acceptance, billing and distribution work, so that accounts consistent.2, keep abreast of the stock status, ensure the timely supply of materials and equipment, give full play to the efficiency of turnover.3, regular cleaning of the warehouse, keep the warehouse tidy and beautiful, so that materials and equipment classification arrangement, storage neatly, accurate quantity.4, familiar with the corresponding materials, equipment varieties, specifications, models and performance, fill in clearly.5, do a good job of warehouse safety management, check the warehouse fire, anti-theft facilities, plugging loopholes in a timely manner.6 、 complete other work assigned by section chief.

- Q:What is the storage fee?

- Warehousing cost is the material supply and marketing enterprises in the purchase of goods, acceptance, warehousing, storage of materials in the process of payment of all costs. Warehousing costs paid to the storage warehouse storage and transportation, as well as the subsidiary enterprise in the warehouse transfer handling, inspection, repair, maintenance, selecting and sorting, packaging, inventory loss, and wages, workers from the welfare expenses and other expenses.

- Q:What are the irrational aspects of warehousing in logistics?

- Integration of logistics function. Modern logistics will focus on other aspects of logistics and supply chain integration, including: logistics channel and logistics flow channel integration, channel integration, between the function of logistics integration, logistics and manufacturing integration etc..

- Q:Common equipment for warehouse logistics equipment

- Three dimensional shelf, conveyor equipment, AGV trolley, reciprocating lift, pallet, etc. 134313 dragon 67497 provide reference!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Heavy Duty Type Pallet Racking System for Warehouse

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords