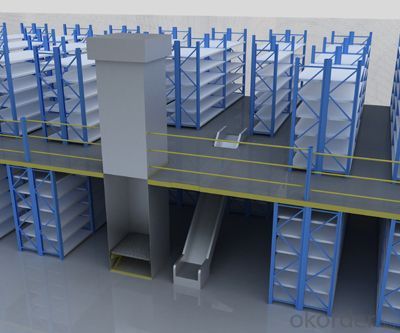

Mezzanine Type Pallet Racking System for Storage

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Desription:

Mezzanine rack uses medium or heavy duty rack for frame and add metal decking.

Mezzanine type pallet rack has good loading good overall, with high precision and smmoth sureface.

Light sytem could be added for it. easy and good for management.

It is widely used in warehouse, logistic centre, and etc.

Feature:

· It could raise height

· Good loading

· Efficient operation

· Easy installation

Images:

Specification:

Loading weight | 500KG |

Space betwwen floors | 2-2.7m |

FAQ:

What is note for purchase?

pallet size,good weight, warehouse sapce and height, etc.

How is quality guaranteed?

The production use professional roll forming technology and material of steel for production have strict test. The finished product into market are all guaranteed for users

How about the project installation?

Drawing for installation is provided for users. We also could send engineers to users's spot to carry out installation.

- Q: What are the key functions of warehouse management logistics informatization construction?

- WMS and automatic identification technology are inseparable, with large technology, a dozen focus on enterprise warehouse management research and development, the success of many large domestic enterprises to solve the problem of warehouse management.According to the existing customer database system for analysis, for each product to establish a bar code identification, bar code bar code printer to print the barcode label, resulting in the sequence number, the relevant information should be included in each of the barcode products. (customized by the customer) can include the product name, specifications, quantity, bar code serial number, date of warehousing and date of delivery. ---- initial information collection, EBIG logistics and warehousing management system (WMS)

- Q: How to strengthen the integration and construction of logistics infrastructure

- All kinds of transport stations. Because according to a certain area and goods freight organization characteristics of planning and construction, this function cannot be simply used to replace with the supply chain organization of logistics organization, logistics organization is not equal to the freight organization, and can form a freight logistics organization in the process, but not all social goods. As a part of the cargo for the enterprise supply chain implementation in the space layout requirements of the organization according to the logistics, freight station has meet the service needs of the decentralized logistics organization function is a must, therefore, besides having the function of freight freight station node, need to upgrade or enrich its service function.

- Q: What are the storage facilities and equipment included?

- When the warehousing industry exists as a format, logistics is an effective means to realize value-added services, and warehousing is an indispensable node in the logistics industry.The development of modern logistics industry needs the support of modern warehouse management, and the advanced technology of informatization and the guidance of information technology has become an effective way for the warehousing industry to modernize.

- Q: What are the advantages of automated warehousing and its role in logistics systems?

- The loss caused by the quality of operation is greater. On the one hand is the traditional plane warehouse logistics automation level is low, the goods into the library is the basic manual use of forklift operation, due to improper operation will cause artificial goods collision loss; on the other hand is because of the wrong operation or cost error caused by the error distribution, especially the distribution of medicines, will cause more serious consequences.

- Q: What are the problems in e-commerce, logistics and warehousing?

- The development of e-commerce depends to a large extent on the logistics enterprises to maintain high quality of service and flexibility, and control and reduce the cost of logistics. But in the logistics industry, some enterprises are empty of vehicles, idle warehouses, while many enterprises are looking for vehicles and warehouses. This shows that the social freight and warehousing resources are not short, and the lack of integration resources between enterprises. Therefore, the application of logistics technology now, the electronic commerce logistics enterprises scattered alliance, forming a service network, is the best way to reduce the cost of logistics and distribution, e-commerce to improve the level of development of e-commerce logistics.

- Q: What are the common logistics equipment?

- According to the service scope of equipment in the logistics activities, it can be divided into enterprise (production), logistics equipment and social (supply and marketing) logistics equipment. Enterprise logistics equipment enterprise fixed assets is part of belonging to the enterprise of its own equipment, such as transport vehicles, the railway line, handling machinery, packaging machinery, storage and construction: social logistics equipment logistics services for the community, belong to utilities, such as transport routes, stations, ports, bridges and tunnels

- Q: What is the warehousing logistics distribution center?

- The distribution center must first purchase the goods to be supplied and distributed in order to supply materials to its users, that is, manufacturing enterprises or commercial enterprises, in a timely and accurate manner. The distribution center shall formulate and adjust the unified and comprehensive purchasing plan according to the change of supply and demand in the market, and shall be organized and implemented by special personnel and departments.

- Q: What aspects of logistics and warehousing management?

- Should meet the following requirements in the general layout of warehouse: (1) abide by the laws and regulations of various buildings and facilities planning; (2) to meet the requirements of warehouse operation smoothly, avoid repeated handling circuitous transportation; (3) ensure the storage of goods safety; (4) ensure the working safety; (5) the maximum use the warehouse area; (6) to make full use of warehouse facilities and equipment; (7) comply with the security and fire protection requirements; (8) consider warehouse expansion requirements.

- Q: Storage facilities and equipment is not perfect, what?

- Increase the hardware input to the warehouse.This includes warehouse construction and renovation, purchase of new shelves, pallets, digital automatic identification system and sorting, processing, packaging and other logistics equipment, greatly enhance the level of automation of existing warehouse and logistics operation efficiency, increase the function of logistics services.

- Q: Common equipment for warehouse logistics equipment

- Warehouse logistics: solid shelves, stacking machines, sorting lines, conveyor equipmentVertical conveying type: Reciprocating lift, continuous elevator, intermittent elevator and hydraulic lifting platformFlat conveyor: belt conveyor, chain machine, roller and other non-standard conveying equipmentNon-standard equipment: climbing belt conveyor (chain machine), turning belt conveyor (chain machine), screw conveyor, etc.

Send your message to us

Mezzanine Type Pallet Racking System for Storage

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords