Steel Paltfrom Type For Warehouse Storage

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

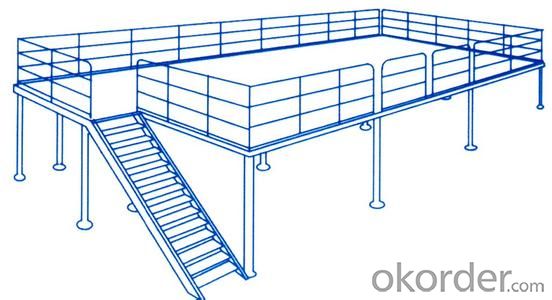

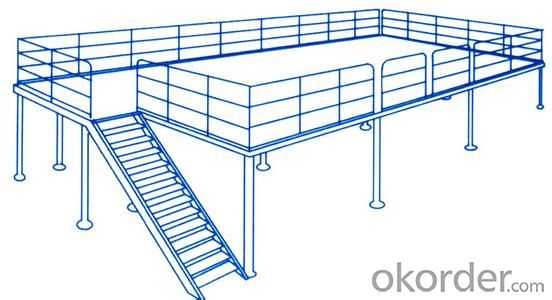

It ‘s steel platform, one type of pallet racking system, also called attic shelf or multi layer racking system.

It is suitable for limited space of warehouse and could have multi layers two or three.

Feature:

· Ladder or hydraulic lift for upstair.

· Metal floor.

· For different goods.

· Frame suppor the floor.

Images:

Specification:

Loading Capacity | 500KG/sqaure meter |

Beam Space | 3-5 meter |

Height | customized |

FAQ:

What is steel platform ?

Steel platform is used in factory for space usage, usually have 2-3 floors and have big loading capacity. Ladder is equipped for going upstairs.

How is quality guaranteed?

The production use professional technology and material of steel for production have strict test. The finished product into market are all guaranteed for users

How about the project installation?

Drawing for installation is provided for users. We also could send engineers to users's spot to carry out installation for project.

- Q: How to strengthen the integration and construction of logistics infrastructure

- Specialized facilities. Is the different links in the supply chain, in different places with support to the supply chain, supply chain management to meet the individual functional requirements, or to a single function, professional facilities with other auxiliary functions, the facilities are in accordance with their own needs and characteristics of the service object layout function setting, these facilities including a variety of modes of transport hubs and stations, storage facilities, etc..

- Q: What are the irrational aspects of warehousing in logistics?

- Rapid logistics reaction. The logistics service provider on the upstream and downstream logistics and distribution demand response faster, shorter lead time, distribution interval is shorter and shorter, logistics faster, more and more commodity turnover.

- Q: What are the advantages of automated warehousing and its role in logistics systems?

- Information flow and logistics can not be unified in time. On the one hand, the traditional warehouse is often low level of information technology, resulting in low level of overall logistics management, unable to provide customers with high-quality and flexible logistics services. On the other hand, because of the information flow and logistics can not be unified, resulting in the error costs described above, so that the overall cost of warehousing increased.

- Q: What is the warehousing logistics distribution center?

- The distribution center must first purchase the goods to be supplied and distributed in order to supply materials to its users, that is, manufacturing enterprises or commercial enterprises, in a timely and accurate manner. The distribution center shall formulate and adjust the unified and comprehensive purchasing plan according to the change of supply and demand in the market, and shall be organized and implemented by special personnel and departments.

- Q: The differences and advantages between warehouse logistics and ocean shipping logistics

- Warehouse logistics is the use of self built or leased warehouse, site, storage, storage, handling, delivery and distribution of goods. The traditional definition of warehousing is given from the point of view of material reserves. Modern warehousing is not the traditional "warehouse" or "warehouse management", but "warehousing" under the background of economic globalization and supply chain integration. It is the warehouse in the modern logistics system.Ocean (Freight) is broadly defined as all Yu Hai related business activities. But to the present day, the maritime transport we have mentioned is generally referred to as the transportation of the sea, such as bulk cargo transportation and container transportation.

- Q: The advantages and disadvantages of logistics line type I U type L

- I logistics center has a separate entry and exit goods, which are distributed in the logistics center on both sides, straight to the point (Figure 1). Due to the I logistics center operation flow is linear, the operation of parallel lines, so whether people or logistics, collision mutually cross points is relatively minimal, can reduce the possibility of operators and logistics handling car collision.The biggest problem existing in I logistics center is the entry and exit goods Taiwan far apart, the overall increase in cargo transportation routes, reducing efficiency, but the linear process is relatively simple, relatively easy to adapt to the operator, can make up for deficiencies in this area. In addition, as the exit and arrival platform is located on both sides of the logistics center, at least two teams of security teams are responsible for the supervision of the two goods stations, increasing personnel input and operating costs.

- Q: The disadvantages of traditional warehousing and the advantages of modern warehousing

- The traditional warehouse logistics function is unitary, the informationization level is low, the service level and the ability are not high, is unable to adapt to the Chinese socialism market economy new situation and the international economic integration development tendency

- Q: Storage facilities and equipment is not perfect, what?

- In order to adapt to the rapid expansion of warehouse operation, storage industry needs to greatly improve automation. For example, we need to use more delivery to deliver small items over long distances while setting an appropriate number of repacking stations and loading and unloading platforms. In addition, if we use more automatic sorting equipment, we can improve the overall work capacity without building additional sites. As a result, automated equipment will continue to replace labor in operations such as cargo handling, which add little or no value.

- Q: What are the third party logistics? What are the advantages and disadvantages?

- 3PL can meet these requirements in a fast and cost effective way that is often difficult to achieve by manufacturers alone. Similarly, 3PL also has the ability to meet the potential customer needs of manufacturing firms, thereby contributing to the communication between producers and retailers.

- Q: What are logistics facilities and equipment?

- Logistics facilities and equipment are the material and technical basis for organizing and conducting logistics activities.

Send your message to us

Steel Paltfrom Type For Warehouse Storage

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords