trapezoidal corrugated Roof Panel Forming Machine 1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 300000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Components

1.Manual Decoiler: one set

Un-powered,Manually control steel coil inner bore shrinkage and stop,

Max Feeding width: 1250mm,coil ID range 508mm±30mm

Capacity: Max. 5 Ton

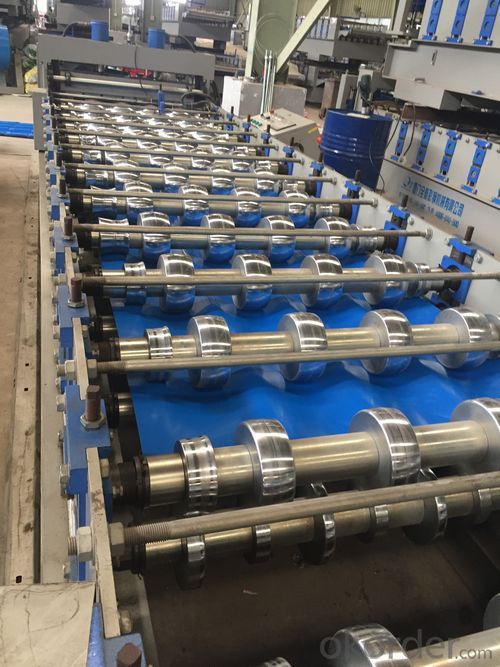

2. Main machine

With feeding material guide, body frame made from H350 type steel by welding;

Rollers manufactured from 45# steel,CNC lathes,Heat Treatment, hard Chrome Coated;

Shafts Diameter=ф75mm,precision machined

Gear/Sprocket driving, about 18-step to form

Main Motor=5.5KW , Frequency speed control

Forming speed approx.13-15m/min

3. Hydraulic Cutting device:

Cutter frame made from high quality 20mm steel plate by welding

Post cut, stop to cutting,Two pieces cutting blades,no blanking

Hydraulic motor: 2.2KW Cutting pressure: 0-12Mpa

Cutting tool material: Cr12, Heat treatment

4. PLC Control System

Control the quantity and cutting length automatically

Combined with: PLC, Inverter, Touch Screen, Encoder, etc

PLC: Delta brand (Taiwan)

Inverter: Delta brand (Taiwan)

Touch Screen: WEINVIEW brand (Taiwan)

Encoder: KOYO brand (Japan)

Cut-to-length tolerance≤±2 mm

5. User's manual in English

- Q: What are the storage facilities and equipment included?

- When the warehousing industry exists as a format, logistics is an effective means to realize value-added services, and warehousing is an indispensable node in the logistics industry.The development of modern logistics industry needs the support of modern warehouse management, and the advanced technology of informatization and the guidance of information technology has become an effective way for the warehousing industry to modernize.

- Q: What are the commonly used automation equipment in warehouse logistics?

- Such as the commonly used transport equipment, the car these

- Q: Logistics warehousing problems?

- Logistics management between producers and consumers play an important media distribution center, through the logistics pipeline to improve, not only consumers can enjoy fast and convenient services, the producers also can quickly provide products, through the process of circulation, through the effective combination of transport and storage management procedures, handling, packaging, distribution processing, and related logistics information function activities, in order to create value, to meet customer and social needs.

- Q: Question: what is the nature of logistics warehousing?

- It will be divided into commercial or industrial land in accordance with specific conditions.

- Q: What are the characteristics of electric power supplies (such as transformers, cables, etc.), mainly in logistics, warehousing and transportation?

- Storage of electric power materials should be prevented from dampness, good rain proof water and moist air intrusion, and electric porcelain equipment should be placed in strict accordance with the requirements, and can not be taken down at will. To prevent collisions and matters should be noted, but also to strengthen ventilation and humidity control and regulation.

- Q: What does the storage equipment mainly consist of?

- 1, horizontal transport equipment, including a variety of vehicles, conveyor belts, belt machines, etc.;2, packaging equipment: including packaging, packaging machinery, yards, equipment and so on;3 、 vertical conveying equipment: hoist, forklift, stacker and so on;4, handling equipment: such as a large crane (gantry container cranes), ship unloading of various professional equipment (car);5 、 Safety Monitoring equipment;6 、 automatic management equipment.

- Q: What is the warehousing logistics distribution center?

- The distribution center is to receive and handle the end user order information, sorting of many varieties of goods shipped upstream, according to user's request for picking, processing, assembly and other operations, and delivery facilities and institutions. Is to accept a lot of goods from suppliers to flip, classification, storage, distribution processing and information processing and other operations, and in accordance with the requirements of many need to order the preparation of goods, delivery facilities with satisfactory service level.

- Q: The differences and advantages between warehouse logistics and ocean shipping logistics

- Warehouse logistics is the use of self built or leased warehouse, site, storage, storage, handling, delivery and distribution of goods. The traditional definition of warehousing is given from the point of view of material reserves. Modern warehousing is not the traditional "warehouse" or "warehouse management", but "warehousing" under the background of economic globalization and supply chain integration. It is the warehouse in the modern logistics system.Ocean (Freight) is broadly defined as all Yu Hai related business activities. But to the present day, the maritime transport we have mentioned is generally referred to as the transportation of the sea, such as bulk cargo transportation and container transportation.

- Q: The advantages and disadvantages of logistics line type I U type L

- The logistics centre that deals with fast freight goods usually uses the L concept design to minimize the flow of goods to and from the logistics centre and to the L (Figure two). The L type logistics center is similar to the I type logistics center, and also has two independent goods stations, fewer collision intersections, and is suitable for dealing with fast moving goods.One of the limitations of L type logistics centers is that the efficiency of the goods in other functional areas will be reduced relative to the L range. Therefore, the logistics center of this type is usually at the same time dealing with the "fast flow" and "slow" goods, the "fast flow of goods stored in the L flow range, the" slow flow "of the goods stored in the L flow range, according to the frequency of the effective use of goods handling logistics center the various functional areas.This type of logistics center is particularly suited for cross - operation (cross-docking), handling some "come on" or "only a short stay in the logistics center". Hongkong L type logistics center is less, more common in China, such as Shenzhen Kerry Yantian Port Logistics center.

- Q: What shelves are there in the logistics equipment?

- The total number of logistics equipment has increased rapidly. In recent years, China's logistics industry has developed rapidly, and has been paid great attention by governments at all levels, in this context, the overall number of logistics equipment increased rapidly, such as transport equipment, storage equipment, distribution equipment, packaging equipment, handling equipment (such as forklift, crane), logistics information equipment etc..The level of automation and informatization of logistics equipment has been improved. In the past, our logistics equipment was mainly manual or semi mechanized, and the efficiency was low. However, in recent years, the logistics equipment in its automation level and the degree of informatization has been improved, and work efficiency has been greatly improved.Basically, the logistics equipment production, sale and consumption system has been basically formed. In the past, logistics equipment was often required, but it was difficult to find the corresponding production enterprises, or logistics equipment production, but because of imperfect sales system and insufficient demand, the production of logistics equipment could not be completed continuously. At present, the system of production and sales, consumer logistics equipment has been basically formed, the domestic logistics has a number of professional equipment manufacturers, equipment sales of professional logistics companies and a number of logistics equipment, consumer groups, making the logistics equipment can be gradually improved and the development of the system in production, distribution and consumption in.

Send your message to us

trapezoidal corrugated Roof Panel Forming Machine 1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 300000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords