trapezoidal corrugated Roof Panel Forming Machine 1100mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 300000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main Components

1.Manual Decoiler: one set

Un-powered,Manually control steel coil inner bore shrinkage and stop,

Max Feeding width: 1250mm,coil ID range 508mm±30mm

Capacity: Max. 5 Ton

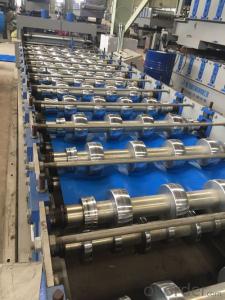

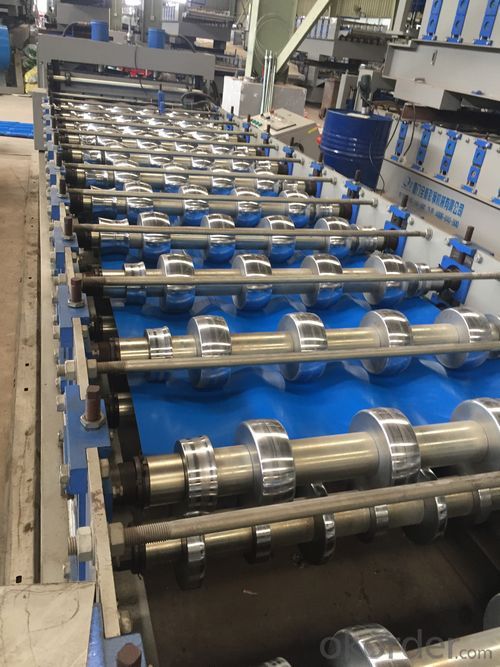

2. Main machine

With feeding material guide, body frame made from H350 type steel by welding;

Rollers manufactured from 45# steel,CNC lathes,Heat Treatment, hard Chrome Coated;

Shafts Diameter=ф75mm,precision machined

Gear/Sprocket driving, about 18-step to form

Main Motor=5.5KW , Frequency speed control

Forming speed approx.13-15m/min

3. Hydraulic Cutting device:

Cutter frame made from high quality 20mm steel plate by welding

Post cut, stop to cutting,Two pieces cutting blades,no blanking

Hydraulic motor: 2.2KW Cutting pressure: 0-12Mpa

Cutting tool material: Cr12, Heat treatment

4. PLC Control System

Control the quantity and cutting length automatically

Combined with: PLC, Inverter, Touch Screen, Encoder, etc

PLC: Delta brand (Taiwan)

Inverter: Delta brand (Taiwan)

Touch Screen: WEINVIEW brand (Taiwan)

Encoder: KOYO brand (Japan)

Cut-to-length tolerance≤±2 mm

5. User's manual in English

- Q: What are the basic principles of warehousing?

- Warehouse management is the material of the warehouse and warehouse in the management, is to provide efficient storage service with storage mechanism in order to make full use of the storage resources planning, organization, control and coordination process.

- Q: What are the logistics facilities and equipment in the supermarket?

- Supermarket trolleys, logistics and warehousing facilities; cage, hand basket, supermarket shopping cart, shopping cart, cart, logistics, vehicle logistics, tally, parity, plastic trolleys, shelves and logistics equipment, storage shelves, supermarket shelves, pallets, cashier, wood products, Vegetable & Fruit frame, truck, supermarket the supermarket shopping facilities, supporting facilities, electronic products, storage equipment, tool cart, flat cart, mobile station car, hanging plate rack, pallet stacker, forklift, hydraulic car, metal products, etc..

- Q: The role of warehouse management in Enterprises

- Its functions and tasks are mainly:1, the use of market economy means to obtain the largest allocation of storage resources.2, the principle of high efficiency organization management.3, continue to meet the needs of the community as the principle of business activities.4, with high efficiency, low cost as the principle of organizing warehouse production.5, to high-quality services, credit, establish corporate image.6, through the institutionalization, scientific advanced means, and constantly improve the management level.7, from technical to spiritual areas to improve staff quality.

- Q: What are the responsibilities of the warehouse and logistics department?

- Material storage environment must be kept clean and beautiful. Make sure that the materials and facilities in the warehouse are free of dust, and there are no weeds around the cargo yard and the temporary cargo yard.The storage of the goods should be properly clean, strong safety, reasonable and complete, thatch pad material sign marks. Fixed location of storage of materials to implement the "four position" and "55 stack", and to comply with the quality system, environment / safety management system standards.Warehouse management of inventory must be in accordance with the "six check" content, check, check, check the number of quality measurement tools, storage method, check, check the safety check, serious circulation from the point, since the rate of not less than 50% months, or two months in the inventory of all materials to all at a time. The number of correct inventory requirements, consistent with accounts, no account materials, and make self recording.For materials that need temperature and humidity control, the storage procedures for special requirements must be strictly enforced, daily monitoring of temperature and humidity shall be carried out and records shall be duly made.

- Q: What are the characteristics of electric power supplies (such as transformers, cables, etc.), mainly in logistics, warehousing and transportation?

- Such as the transportation of transformers are usually created by professional transport companies, transport speed and road have very strict requirements, to do the corresponding protection measures, to prevent moisture (filling nitrogen protection) and a sudden stop caused by body displacement etc..

- Q: What are the categories of logistics?

- Social logistics belongs to the macro scope, including equipment manufacturing, transportation, warehousing, distribution, packaging decoration, information services, public logistics and third party logistics through the logistics enterprises; the micro logistics category, including production logistics, supply logistics, sales logistics and recycling logistics and waste material logistics etc..

- Q: What brands of operating equipment are used in the major logistics and express companies in China?

- Many express companies are designed for special companies. They include roller conveyors, electronic packages, sewing racks, sewing machines, wireless guns, trays and the like

- Q: The advantages and disadvantages of logistics line type I U type L

- The logistics centre that deals with fast freight goods usually uses the L concept design to minimize the flow of goods to and from the logistics centre and to the L (Figure two). The L type logistics center is similar to the I type logistics center, and also has two independent goods stations, fewer collision intersections, and is suitable for dealing with fast moving goods.One of the limitations of L type logistics centers is that the efficiency of the goods in other functional areas will be reduced relative to the L range. Therefore, the logistics center of this type is usually at the same time dealing with the "fast flow" and "slow" goods, the "fast flow of goods stored in the L flow range, the" slow flow "of the goods stored in the L flow range, according to the frequency of the effective use of goods handling logistics center the various functional areas.This type of logistics center is particularly suited for cross - operation (cross-docking), handling some "come on" or "only a short stay in the logistics center". Hongkong L type logistics center is less, more common in China, such as Shenzhen Kerry Yantian Port Logistics center.

- Q: What are the third party logistics? What are the advantages and disadvantages?

- 3PL can meet these requirements in a fast and cost effective way that is often difficult to achieve by manufacturers alone. Similarly, 3PL also has the ability to meet the potential customer needs of manufacturing firms, thereby contributing to the communication between producers and retailers.

- Q: What shelves are there in the logistics equipment?

- The total number of logistics equipment has increased rapidly. In recent years, China's logistics industry has developed rapidly, and has been paid great attention by governments at all levels, in this context, the overall number of logistics equipment increased rapidly, such as transport equipment, storage equipment, distribution equipment, packaging equipment, handling equipment (such as forklift, crane), logistics information equipment etc..The level of automation and informatization of logistics equipment has been improved. In the past, our logistics equipment was mainly manual or semi mechanized, and the efficiency was low. However, in recent years, the logistics equipment in its automation level and the degree of informatization has been improved, and work efficiency has been greatly improved.Basically, the logistics equipment production, sale and consumption system has been basically formed. In the past, logistics equipment was often required, but it was difficult to find the corresponding production enterprises, or logistics equipment production, but because of imperfect sales system and insufficient demand, the production of logistics equipment could not be completed continuously. At present, the system of production and sales, consumer logistics equipment has been basically formed, the domestic logistics has a number of professional equipment manufacturers, equipment sales of professional logistics companies and a number of logistics equipment, consumer groups, making the logistics equipment can be gradually improved and the development of the system in production, distribution and consumption in.

Send your message to us

trapezoidal corrugated Roof Panel Forming Machine 1100mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 300000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords