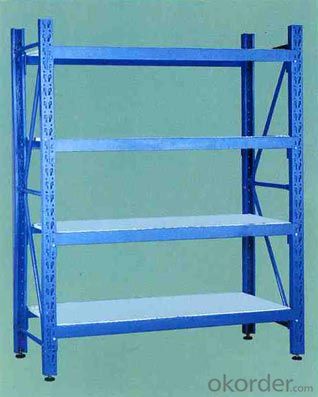

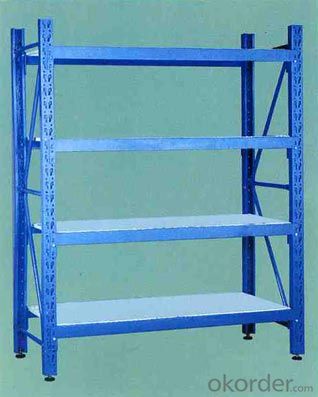

Medium Duty Racking Systems for Warehouses

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Medium duty pallet rackging system is for medium weight goods. It has standard and non standarn type and could be customized for goods, etc. The production adopts advanced roll forming technology and guarantee good quality and high precision. Good material ensure long usage life. It could bear medium weight goods well.

Feature:

· Goodstructure

· Height adjusted

· Big loading

Images:

Specification:

Size | 2000*600*2000 |

Loadging | 200-500 |

FAQ:

What is note for purchase?

Manufactuer background, technology, warehouse space, etc.

How is quality guaranteed?

Good production technology is used is its production.

How about the project installation?

Drawing or engineers installation.

- Q: What are the types of logistics equipment?

- According to the service scope of equipment in the logistics activities, it can be divided into enterprise (production), logistics equipment and social (supply and marketing) logistics equipment. Enterprise logistics equipment enterprise fixed assets is part of belonging to the enterprise of its own equipment, such as transport vehicles, the railway line, handling machinery, packaging machinery, storage and construction: social logistics equipment logistics services for the community, belong to utilities, such as transport routes, stations, ports, bridges and tunnels.

- Q: What are the logistics facilities and equipment in the supermarket?

- Boutique shelves, display rack, rack, titanium alloy, titanium alloy, Variety shelves, racks, steel rack, storage rack, display rack, CD rack, Variety shelves, storage shelves, sample rack, display cabinets, cabinet boutique, boutique shelves.

- Q: How to do the warehouse logistics supervisor?

- Understand the functions of this warehouse. Although the main function of the warehouse is to store and keep the goods, the warehouses of different enterprises have different functions.

- Q: What are the storage facilities and equipment included?

- The warehousing industry of our country will develop in a harmonious atmosphere of the simultaneous growth of construction and demand, and the network, information and advanced information technology will become an effective way to develop it.

- Q: Logistics warehousing problems?

- Logistics management between producers and consumers play an important media distribution center, through the logistics pipeline to improve, not only consumers can enjoy fast and convenient services, the producers also can quickly provide products, through the process of circulation, through the effective combination of transport and storage management procedures, handling, packaging, distribution processing, and related logistics information function activities, in order to create value, to meet customer and social needs.

- Q: What are the problems in e-commerce, logistics and warehousing?

- The development of e-commerce depends to a large extent on the logistics enterprises to maintain high quality of service and flexibility, and control and reduce the cost of logistics. But in the logistics industry, some enterprises are empty of vehicles, idle warehouses, while many enterprises are looking for vehicles and warehouses. This shows that the social freight and warehousing resources are not short, and the lack of integration resources between enterprises. Therefore, the application of logistics technology now, the electronic commerce logistics enterprises scattered alliance, forming a service network, is the best way to reduce the cost of logistics and distribution, e-commerce to improve the level of development of e-commerce logistics.

- Q: What are the categories of logistics?

- Social logistics belongs to the macro scope, including equipment manufacturing, transportation, warehousing, distribution, packaging decoration, information services, public logistics and third party logistics through the logistics enterprises; the micro logistics category, including production logistics, supply logistics, sales logistics and recycling logistics and waste material logistics etc..

- Q: What does the storage equipment mainly consist of?

- Warehousing equipment mainly consists of:1, a variety of specialized warehouses;2. Facilities in the warehouse;3, all kinds of ancillary equipment, such as: explosion protection, fire fighting, metering, temperature measurement, ventilation, information management, etc..

- Q: The disadvantages of traditional warehousing and the advantages of modern warehousing

- The traditional warehouse logistics function is unitary, the informationization level is low, the service level and the ability are not high, is unable to adapt to the Chinese socialism market economy new situation and the international economic integration development tendency

- Q: What shelves are there in the logistics equipment?

- The so-called logistics equipment is necessary for the logistics activities of complete sets of buildings and artifacts, organizations involved in a variety of physical flow of mechanical equipment, transport, storage facilities, station, computer and communication equipment.

Send your message to us

Medium Duty Racking Systems for Warehouses

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords