Backsplash Aluminum Sheets for Curtain Wall Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

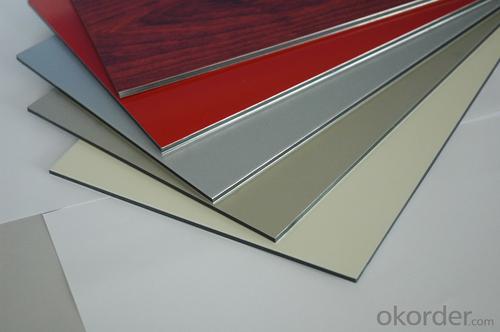

Structure of Aluminium Composite Pannel for Curtain Wall Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Composite Pannel for Curtain Wall:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

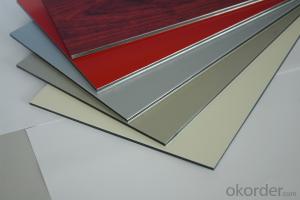

Images of the Aluminium Composite Pannel for Curtain Wall:

Aluminium Composite Pannel for Curtain Wall Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Prepaited Coil:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: This question asks if there are any potential risks or hazards associated with using windows that are manufactured from recycled materials.

- <p>There are generally no significant safety concerns with using windows made from recycled materials. These windows are often made from recycled plastics or glass, which are processed to ensure they meet safety and quality standards. However, it's important to ensure that the recycled materials used are free from contaminants and are processed correctly to maintain structural integrity. Additionally, the manufacturing process should adhere to environmental and safety regulations to prevent any health or environmental risks. Always check for certifications and standards that the windows meet to ensure their safety and reliability.</p>

- Q: What is the melting point of aluminum sheets?

- The melting point of aluminum sheets is approximately 660 degrees Celsius or 1220 degrees Fahrenheit.

- Q: Can aluminum sheets be used for chemical pumps?

- No, aluminum sheets are not suitable for chemical pumps as they are not resistant to corrosion from many chemicals.

- Q: there is a magnet for other type of nails except aluminum nails

- sadly, magnets do not work on aluminum, however, the are light enough, to be picked up by a vacuum.

- Q: What is the weight of aluminum sheets per square foot?

- The weight of aluminum sheets per square foot varies depending on the thickness of the sheet. On average, aluminum sheets weigh around 0.96 pounds per square foot.

- Q: How strong is aluminum per square inch, and at the same time how light is the aluminum per square inch?

- Take a look on this website. You will see some of the main uses of aluminium and will be able to determine what it is capabke of: www.bwcaluminium .uk

- Q: i have a aluminum bicycle the first time i painted it i painted over the original paint(didnt know any better). The second time i sanded it down with some paint left on it. Now this time im sanding it but im using 60grit it looks good to me is 60 grit to much.

- you dont sand aluminum you strip it!

- Q: Is it feasible to use aluminum sheets for constructing exteriors of buildings in regions susceptible to earthquakes?

- <p>Aluminum sheets can be used for building exteriors in earthquake-prone areas, but they must be properly engineered and installed. Aluminum is lightweight and flexible, which can be advantageous in withstanding seismic forces. However, it's crucial to ensure that the aluminum is reinforced with a robust structural system that can distribute the forces during an earthquake. The design must also comply with local building codes and seismic regulations. It's recommended to consult with structural engineers and architects experienced in earthquake-resistant design to ensure the safety and durability of the construction.</p>

- Q: What is the fatigue life of aluminum sheets?

- The fatigue life of aluminum sheets refers to the number of cycles that the material can withstand before failure occurs under cyclic loading conditions. The fatigue life of aluminum sheets can vary depending on various factors such as the alloy composition, thickness, surface finish, loading conditions, and environmental factors. Aluminum is known for its relatively high fatigue strength compared to other materials, making it a popular choice in various industries including aerospace, automotive, and construction. The fatigue life of aluminum sheets is typically influenced by the presence of microstructural defects such as inclusions, voids, and grain boundaries. To determine the fatigue life of aluminum sheets, fatigue tests are conducted using standardized procedures such as ASTM E466 or ASTM E606. These tests involve subjecting the material to cyclic loading conditions, typically at a constant stress or strain amplitude, while monitoring the number of cycles required for failure to occur. The results are then used to generate an S-N curve, which represents the relationship between the applied stress or strain amplitude and the number of cycles to failure. The S-N curve provides valuable information about the fatigue life of aluminum sheets, indicating the stress or strain levels at which the material can withstand a certain number of cycles before failure. It is important to note that the fatigue life of aluminum sheets can be improved through various methods such as alloying, heat treatment, surface treatment, and proper design considerations. In conclusion, the fatigue life of aluminum sheets is a critical factor to consider when designing components or structures subjected to cyclic loading conditions. Understanding the specific properties and characteristics of the aluminum alloy, along with proper testing and analysis, can help determine the fatigue life and ensure the safe and reliable performance of aluminum sheets in various applications.

- Q: Is it possible to utilize aluminum sheets in the construction of environmentally friendly buildings?

- <p>Yes, you can use aluminum sheets to create a green building. Aluminum is a sustainable material due to its recyclability and energy efficiency in production. It has a high recycled content rate, reducing the need for raw material extraction. Additionally, aluminum's lightweight nature can lead to reduced energy consumption in transportation and construction. Its durability and resistance to corrosion can extend the life of a building, further contributing to sustainability. However, it's important to consider the entire lifecycle impact, including the energy used in aluminum production, and to source aluminum responsibly to ensure a truly green building.</p>

Send your message to us

Backsplash Aluminum Sheets for Curtain Wall Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords