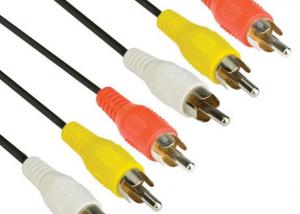

AV Cable

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Pieces pc

- Supply Capability:

- 80000 Pieces per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

AV Cable

RCA Plugs to RCA Plugs

The main products of our company are as following:

Audio/Video Cable, Video Cable, RCA Cable, Scart cable,

Hdmi Cable, Hdmi, Dvi Cable, Hdmi To Hdmi Cable, Hdmi-Hdmi Cable, Hdmi-Dvi Cable

HDMI cable, DVI cable, VGA cable, Optical fiber cable, USB Cable; Rca cable

Computer Cable, Hdmi Cable, Hdtv Cable,

Length: 1m, 2m, 3m, 5m, 10m, 15m, 30m

3ft, 6ft, 10ft, 15ft, 30ft, 50ft, 100ft

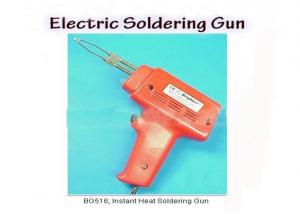

- Q: Electric iron, etc. is not inductive load?

- If it's an electronic soldering iron or a white iron with a power source, it must be an inductive load! Plain iron is a resistive load!

- Q: I use welding wire and some small components to weld the earphone wire

- The nail won't hang on the tin

- Q: When I solder the original with an electric soldering iron, why is it that the solder iron is not smooth and sharp when leaving the solder joint? I'm using 50W's internal heating circuit, iron!

- If the solder is not fused thoroughly, try some rosin (flux) to aid it. If it is a temperature regulating iron, please increase the welding temperature properly.

- Q: How do you handle the oxidation of the electric iron head (almost all of it, especially the head is black)?

- It's useless to change a new one.

- Q: Computer repair shop electric irons, head bent and pointed, very good, how can not see where the iron head to buy it?

- That is our bent, with bending pliers, do you want to buy, the boss can sell it to you, is your bent sell

- Q: I welded the motor coil joint with electric iron. Why couldn't it be welded?

- 1, welding technology is immature, 2, electric iron power is too small, 3, material

- Q: Who tell me what kind of good things come on spot electric iron I had bought an electric iron solder wire 35W will not melt tired and I was in that very fine solder wire to electric iron what kind of wait for a long time to forget the master under the guidance of the best brand louder

- Buy white iron in Japan is quite good (genuine), the price is a little more expensive, but the performance is good.Quick heating, quick heating. I always use it.What if the welding is relatively large, can buy tile a larger number, such as 70W.

- Q: USB interface MP4 is broken, intended to use a soldering iron, but the point is too small, hand flick accidentally put the circuit board somewhere on the skin, green to burn also take the silver contacts to burn hanging did not, the position of the circuit board inside the original point of the brown layer the white color was exposed and the circuit board can also be used? Is the contact still in place? What should I do?

- Sure。The name of the circuit board are: circuit board, PCB board, aluminum substrate, high frequency board, thick copper plate, impedance board, PCB, ultra thin circuit board, ultra-thin circuit board, printing (copper etching technology) circuit board, etc.. The circuit board makes the circuit micro and visual, and plays an important role in the batch production and optimization of the fixed circuit. The circuit board can be called a printed circuit board or printed circuit board, English name (Printed Circuit Board), PCB (Flexible Printed Circuit board [1] (FPC) FPC circuit board circuit board and flexible circuit board flexible circuit board is made of polyimide or polyester film as a base material with high reliability, excellent can flexible printed circuit board. It has the characteristics of high wiring density, light weight, thin thickness and good bending quality And PCB Soft hard (reechas and combination plate), -FPC and the birth and development, the birth of the soft and hard board of this new product. Therefore, the soft and hard board is flexible circuit board and rigid circuit board, through pressing and other processes, according to the relevant process requirements together, formed with FPC characteristics and PCB characteristics of the circuit board.

- Q: W I say is that with the copper iron head, iron head has nothing to do with the heating core (that is popular with the large copper needle)

- When soldering, the temperature of some components can not be too high when welding

- Q: I have a 50W electric iron, a few days ago for a few times, and took in the file on a few, the surface of the black down, and let the iron (hot) with rosin, soon after, very good use, and dark, and I took a few (light), bright after use, can cut off the tip of solder wire, but not only for melting solder, soldering iron head solder melt a little bit later. What's the matter? What's the solution? Do you change the soldering iron head? Which one is best if you want to change?

- The tip of the pointed iron can not be filed with a protective layer. Only the new ones!

Our company is a professional manufacturer and exporter of a wide range of electronic products.We are able to promise prompt delivery and favorable prices to our customers. OEM/ODM orders and your special requests are welcomed. Samples are available upon requests. We sincerely welcome domestic and foreign friends to negotiate trade and cooperation. Please contact us now. Our principle is to make mutual benefits with long-term cooperation. In order to satisfy customers' requirements, we will make great efforts to develop new products and improve our service. We hope to cooperate with all friends from all over the world.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2004 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Northern Europe Southern Europe South Asia |

| Company Certifications | CE |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

AV Cable

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Pieces pc

- Supply Capability:

- 80000 Pieces per Month pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches