BTR-11 Flat Nose Plier 160mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We supply different types of pliers & cutters:

Mini Plastic Nippers / Cutters

Diagonal / Long Nose / Bent Nose Nippers

We are a direct manufacturer of electrical tools with experience of more than 25+ years. With our well experience and the stricted quality control, our company has become famous in many markets over the world. Our annual production quantity is two millions pieces for assorted models.

Agents or distributors wanted. OEM is welcome!!

We supply different types of pliers & cutters:

Mini Plastic Nippers / Cutters, 115mm

Plastic Nipper, 125mm / 150mm

Diagonal Nippers, 115mm

Long Nose Nipper, 150mm / 200mm

Bent Nose Nipper, 150mm

Neddle Nose Nipper, 150mm

Fishing Plier, 160mm

Bent Fishing Plier, 160mm

Big-Head End Cutter, 163mm

Flat Nose Plier, 115mm / 125mm / 160mm

Micro-cutter, 125mm

Electric Heat Nipper

.... etc.

Other products from us:

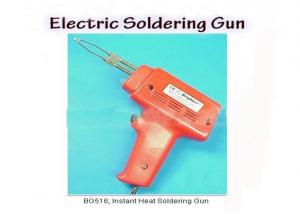

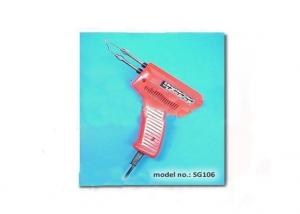

Electric Soldering Irons / Guns

Hot Melt Glue Guns & Glue Sticks

Travel Steamers

Briflon PTFE Adhesive Tape

NeoTech Printer Cartridges

- Q: Where does Taiyuan sell electric irons and commonly used electronic components?

- Look at it online. It's cheaper

- Q: Can spring be welded with electric iron?

- Spring can use electric soldering iron, electric soldering iron when the need to use the low temperature of WEWELDING88C welding wire with 88C-F welding flux, welding Weiouding before a soldering iron with electric spring introduces the topic you can refer to.Tools and materials: a tool can be used as capillary electric iron welding (here is similar to the use of a detailed understanding of a subject "electric iron welding stainless steel"), small and medium thick pieces can be flame welding using third generation of liquefied gas special porous material: stainless steel wire gun WEWELDING88C low temperature (WE88C low temperature stainless steel wire) WE88C-F, flux.The use of the working principle and matters needing attention of WEWELDING88C low temperature welding using all available sources of the parent welding position is heated to about 200 degrees, depending on the parent melt heat conduction welding wire forming, molding process to keep the premise of Wei WE88C-F flux working under the effect of Odin, attention is not deliberately use the flame to burn wire and flux, the focus is on don't let the parent process will heat temperature or overheating.

- Q: When soldering electronic components, what will happen if the soldering iron stays too long at the solder joint?

- Cause overheating damage to components, resulting in copper foil off the printing plate.

- Q: Turn the button on the handle to the left or right, and turn the temperature up

- Turn the knob to the right to raise the temperature. When it is used, don't turn the temperature up so as not to burn out the temperature regulating circuit

- Q: Recently to go to Jiangsu on business, need to bring tools, which have electric irons, do not know when to let the security band!

- An electric iron can carry an airplaneAircraft contraband:Examples of prohibited items are as follows:(a) firearms, including shotguns, air guns, cattle, narcotic, slaughter machines, push guns, signal guns, rifles, ammunition, copying or imitation firearms, crossbows.(b) explosives, including military, commercial or homemade explosives, explosives, detonators, bullets, tear grenades, mines and other explosive ammo, copy or imitation of explosivesOr device.(c) original or adapted to cause injury or sharp knife, blade object, gravity knife, sword, daggers, machetes, or other broad head real ceremonyInstrument with the knife, regardless of what is the blade length or type, including sheath knives, daggers, swords, small razors, scalpels, icepick, sword, sword sticks, hidden in the bladeAn umbrella, spear, spear, or arrow.(d) substances containing substances that are harmful to human beings, including tear gas, mace, tear gas, and various types of phosphite.(E) highly flammable substances (e.g. gasoline, lighters, fuels, etc.).(f) gas containers and sprayers with a capacity of more than 500 ml..(g) flail brass knuckles, bat, and the threshing stick.

- Q: What effect does the electric iron plug in and the electric iron head on the ground?

- On the floor after overheating, thermal expansion and contraction, the floor will be broken, the electric iron head without any problems, because the electric iron head temperature is rated.

- Q: How does electric iron head often oxidize how to do? And sometimes it's not tin

- Yes, they are. They are made in japan. When use, pay attention to the temperature should not be too high, often use high temperature sponge to wipe, keep the soldering iron head always have tin, stop the power off a little tin

- Q: HAKKO 936 constant temperature electric iron temperature not constant, how should I do?

- The thermocouple is out of order

- Q: Adjustable temperature soldering iron power line company is three inserted, but there is a adjustable jack with a grounding wire clip, I opened it, the ground wire and the power line is connected with the hole, but the resistance received jack with a 1M there. Excuse me, what is this principle, so take what role did not feel ah.

- That is anti-static, should be attached to your anti-static wrist strap, to prevent human electrostatic damage to components, and resistance is to control the discharge current, there will be no electric shock feeling.You can be confirmed from the electrostatic, the body often with static electricity, especially in dry weather higher voltage, sometimes touching the metal causes a spark, electric shock feeling. So in the electronic circuit assembly operation in order to prevent electrostatic breakdown components need to be grounded in the body to eliminate static electricity, to avoid electric shock when wiring 1M sense resistor limits the discharge current, because the total charge is not much, although the 1M resistance is large, also to ensure sufficient to release the safety requirements of components.

- Q: I want to buy an electric iron, but do not know the heat sponge and what is the use of a solder paste.

- Electric iron in heating to the highest temperature, the electric iron coated with flux to stick on the tin coated flux is non stick tin, copper contact there is in you also to apply welding welding, and then use your electric iron to poke the copper contact to welding. And quite strong, if not prefluxing copper contact even if welding is forced up weld, is not very firm. Then the effect of heat-resistant sponge: electric iron head is copper, copper oxide black copper oxide in the heating state for a long time, there is a small amount of tin oxide, so the tip surface covered with a layer of copper oxide film and tin oxide, tin to prevent adhesion, heat resistant sponge come in handy here, you use the electric iron heating in the sponge grinding back and forth a few will be able to get rid of the oxide layer and tin oxide, then you can directly apply flux can be used, it is best not to pay attention to scrape the iron head with a knife in the film, easy to damage the iron head, or a lot, but said quite clear, that is, not what esoteric, heating type electric iron is easy to learn.

1. Manufacturer Overview

| Location | Kowloon, Hong Kong |

| Year Established | 1971 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

BTR-11 Flat Nose Plier 160mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 100000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords