Austenitic Seamless Steel Pipe 316L 00Cr17Ni14Mo2

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1、Structure of Austenitic Seamless Steel Pipe 316L Description:

Stainless Steel 316L Pipe is also known as austenitic stainless steel alloy. It offers tremendously high resistance to pitting and crevice corrosion in the chloride conditions. With its austenitic structure it imparts extremely high hardness even at low cryogenic temperature ranges. Stainless Steel 316L Pipe offers stress to rupture, large tensile strength and creeping resistance at the elevated temperature ranges.

2、Main Features of the Austenitic Seamless Steel Pipe 316L :

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Excellent weldability

• Highly tough

•Tremendous resistance to corrosion in the various media and oxidation

3、Austenitic Seamless Steel Pipe 316L Images:

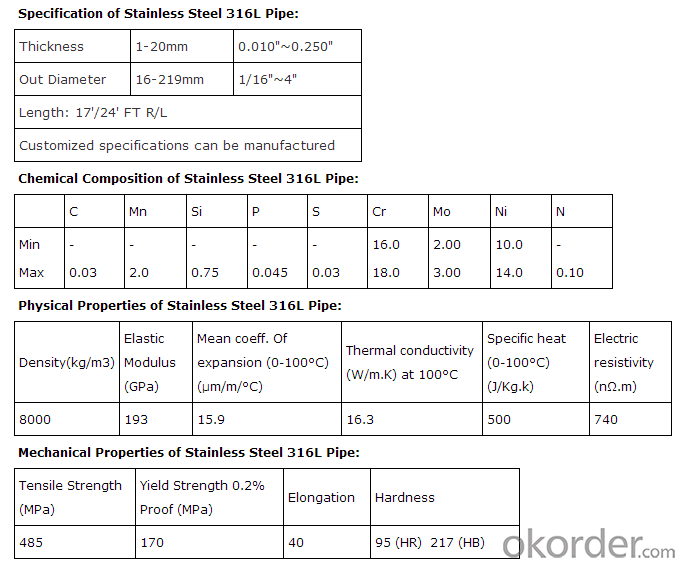

4、Austenitic Seamless Steel Pipe 316L Specification:

Product name: AISI stainless steel pipe/tube

Materials: 304, 304L, 310S, 316, 316L, 325, 273, 219 and 168

Thickness: 1, 2, 2.5, 3, 3.5, 4, 5, 6 and 8mm

Outer diameter: 6-480mm

Length: as required

Treatment: cold and hot rolled

Applications: construction upholstery, and industry instruments, such as fencing, railing,safe doors/windows, gate fittings, inside staircases, balcony balustrades, furniture, sanitary wares and kitchen wares

Standards: GB, AISI, ASTM, DIN and JIS

Sureface: 2B, BA and designer finishes

Price terms: FOB, CIF, CFR and EXW

Delivery:10-15 days after received the deposit or as quantity request.

Chemical Composition | C | Mn | P | S |

<=0.0< span="">3 | <=2.00< span=""> | <=0.0< span="">35 | <=0.03< span=""> | |

Si | Cr | N | Ni | |

<=1.00< span=""> | 16-18 | NO | 12-15 |

5、FAQ of Austenitic Seamless Steel Pipe 316L :

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q: What are the safety regulations for working with steel pipes?

- The safety regulations for working with steel pipes vary depending on the specific tasks involved, but some common regulations include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots, ensuring proper ventilation in enclosed spaces, following proper lifting techniques to prevent back injuries, implementing proper fall protection measures when working at heights, and using caution when handling tools and equipment to prevent accidents and injuries. It is important to consult the relevant guidelines and regulations specific to your jurisdiction and industry to ensure compliance and promote a safe working environment.

- Q: What are the different methods of pressure testing steel pipes?

- There are several methods of pressure testing steel pipes, including hydrostatic testing, pneumatic testing, and ultrasonic testing. Hydrostatic testing involves filling the pipe with water and applying pressure to check for leaks or weaknesses. Pneumatic testing uses compressed air or gas to pressurize the pipe and detect any leaks or failures. Ultrasonic testing utilizes high-frequency sound waves to inspect the pipe's integrity by detecting any flaws or defects.

- Q: How are steel pipes measured and sized?

- Steel pipes are commonly measured and sized based on their outer diameter (OD) and wall thickness. The OD is measured using a caliper or tape measure, while the wall thickness can be determined by either a micrometer or ultrasonic thickness gauge. This information is crucial for classifying pipes into various standardized sizes, such as schedule or nominal pipe sizes, which are widely used in the industry.

- Q: Are steel pipes suitable for underground gas distribution?

- Yes, steel pipes are suitable for underground gas distribution. Steel pipes are widely used in gas distribution systems due to their high strength, durability, and resistance to corrosion. They are able to withstand the pressure and stress of underground conditions, making them a reliable choice for transporting gas. Additionally, steel pipes have the advantage of being able to handle high temperatures and are resistant to fire, making them a safe option for underground gas distribution. However, it is important to ensure that the steel pipes used are properly coated and protected against corrosion to ensure their longevity and prevent any potential leaks or damage.

- Q: How are steel pipes used in the manufacturing of structural frameworks?

- Steel pipes are commonly used in the manufacturing of structural frameworks due to their strength, durability, and versatility. They provide a reliable means of connecting and supporting various components, allowing for the creation of robust and stable structures. Steel pipes are often used as columns, beams, and braces, providing essential support and stability to buildings, bridges, and other infrastructure projects. Additionally, steel pipes can be easily customized and fabricated to meet specific design requirements, making them a popular choice in the construction industry.

- Q: Theoretical weight of 25*25*1.5 square steel tubes

- Theoretical weight can be directly from the steel tube under the table look up, you can also press type calculation:Weight per meter =4x, wall thickness x (side length - wall thickness) x0.00785. The length of the square tube and the wall thickness are in millimeters, and the weight of each square meter is in kilograms.

- Q: How are steel pipes used in the manufacturing of machinery?

- Steel pipes are used in the manufacturing of machinery for various purposes such as conveying fluids, gases, or materials, as structural components, and for heat transfer. They provide durability, strength, and resistance to corrosion, making them suitable for applications where high pressure, temperature, or heavy loads are involved.

- Q: What is the abrasion resistance of steel pipes?

- Steel pipes have a relatively high resistance to abrasion. They possess exceptional strength and durability, rendering them resilient against the detrimental effects of friction and impact. This quality positions steel pipes as a prime option for various industries and applications that frequently encounter abrasion, such as mining, oil and gas, and the transportation of abrasive substances. Furthermore, steel pipes can be fortified with coatings or linings to enhance their resistance against abrasion, tailored to meet the unique demands of each application. In conclusion, steel pipes present a dependable and enduring solution for effectively managing abrasive materials and environments.

- Q: What is the difference between steel pipes and ductile iron pipes?

- Steel pipes and ductile iron pipes are both commonly used for conveying fluids and gases, but they have notable differences. The main distinction lies in their composition and properties. Steel pipes are made of an alloy of iron and carbon, providing them with high strength and durability. On the other hand, ductile iron pipes are composed of iron, carbon, and small amounts of other elements such as silicon and manganese, which make them more flexible and resistant to bending. Ductile iron pipes also have superior corrosion resistance compared to steel pipes. Overall, steel pipes are preferred for applications requiring higher strength and pressure resistance, while ductile iron pipes are often chosen for their flexibility and corrosion resistance.

- Q: How are steel pipes used in the chemical processing industry?

- Steel pipes are commonly used in the chemical processing industry for various purposes such as transporting chemicals, gases, and liquids, as well as for structural support and containment. They are highly durable, corrosion-resistant, and can withstand high temperatures and pressures, making them ideal for handling and conveying hazardous substances safely.

Send your message to us

Austenitic Seamless Steel Pipe 316L 00Cr17Ni14Mo2

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords