ASTM A516 Grade 70 Pressure Vessel Steel Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

ASTM A516 Grade 70 Pressure Vessel Steel Plate

Detailed Information of ASTM A516 Grade 70 Pressure Vessel Steel Plate

| C | Si | P | S | yield Strength MAp | Tensile strength MAp | Elongation % | ||

| A36 | 0.24 | 0.4 | 0.045 | 0.03 | 250 | 400-520 | 26 | |

| C | Si | Mn | P | S | Cu | |||

| A283 | ≤0.27 | 0.15-0.4 | ≤0.9 | ≤0.035 | ≤0.04 | ≥0.2 | ||

| Thickness: | 6mm, 8mm, 12mm, 16mm, 20mm, 25mm, 30mm, 50mm, 80mm, 100mm, 150mm, 200mm | |||||||

| Width: | 1500mm, 1800mm, 2000mm, 2200mm, 2500mm | |||||||

| Length: | 6000mm, 8000m, can cut to width and length | |||||||

| Packing Details; | according to customer‘s require or export’s standard | |||||||

| Delivery time; | 7 days for stock sizes, 20-25 days for new production sizes | |||||||

| Port: | Tianjin China | |||||||

Related Products Overviews of ASTM A516 Grade 70 Pressure Vessel Steel Plate

Product Name | Typical Grades | Diameter(mm) | Standard Adopted |

Carbon Steel | 20 (1020/S20C/C22) |

Ø16-Ø300 |

GB/SAE/ JIS/DIN |

40 (1040/S40C/C40) | |||

45 (1045/S45C/C45) | |||

Bearing Steel | GCr9 (51100/SUJ1) |

Ø12-Ø250 | |

GCr15 (52100/SUJ2/100Gr6) | |||

GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) |

Ø12-Ø250 | |

40Cr (5140/SCr440/41Cr4) | |||

42CrMo(4140/SCM440/42CrMo4) | |||

Gear Steel | 20CrNiMo |

Ø16-Ø600 | |

20CrMn(5115/SMnC420/20MnCr5) | |||

20CrNiMo(8620/SNCM220/20CrMiMo2) |

Related Products Application of ASTM A516 Grade 70 Pressure Vessel Steel Plate

Carbon Steel | l Mold bottom l Plastic mold l Construction machinery parts l Automobile parts l Security grills l Screens l Construction |

Bearing Steel | l Aerospace l Navigation l Nuclear energy l Chemical industry l Electronic information l Petrochemical l Instrument and meter l Transportation |

Cr-Mo Steel | l Mechanism & Fasteners gear l Stressed components for vehicles l Engines and machines l Parts of larger cross-section |

Gear Steel | l All kinds of gears l Statically and dynamically stressed component for vehicles l Engines and machine l Larger cross-section parts l Crankshafts |

Company Introduction of ASTM A516 Grade 70 Pressure Vessel Steel Plate

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service | l CNBM provides the services and support you need for every step of our cooperation. We’re the business partners you can trust; you can relax and get on with doing business. l For any problem, please kindly contact us at any your convenient time, we’ll reply you in our first priority within 24 hours

|

Advantages

| l Industry experience over 20 years. l Shipment of goods -More than 70 countries worldwide. l The most convenient transport and prompt delivery. l Competitive price with best service. l High technical production line with top quality products. l High reputation based on best quality products.

|

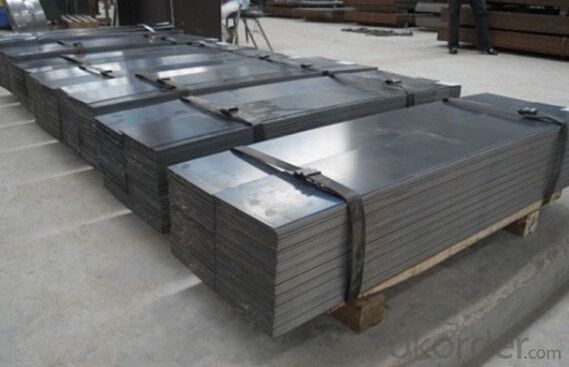

Packaging & Delivery of ASTM A516 Grade 70 Pressure Vessel Steel Plate

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

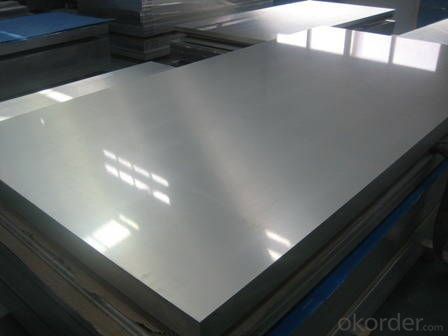

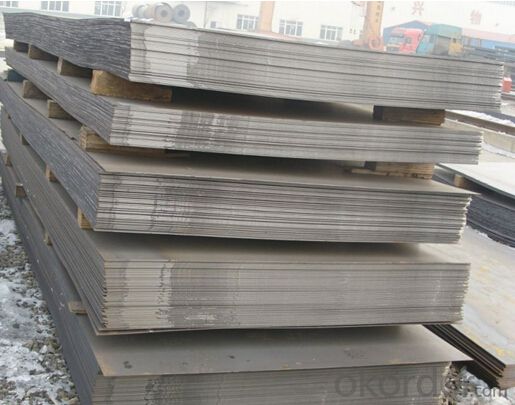

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What grade of iron powder should be used for processing special steel? Are there any other elements on the request? How much are they?

- Special steel into high quality carbon steel, alloy steel, high alloy steel (alloy element is greater than 10%) three categories, including alloy steel and high alloy steel special steel production accounted for 70%.

- Q: How is heat-resistant steel used in high-temperature applications?

- Heat-resistant steel is used in high-temperature applications due to its ability to withstand extreme heat without losing its structural integrity. It is commonly used in industries such as aerospace, automotive, power generation, and petrochemical, where components are exposed to high temperatures. This steel is used to manufacture parts like turbine blades, exhaust systems, heat exchangers, and furnaces, ensuring reliable performance and preventing premature failure at elevated temperatures.

- Q: What are the main factors affecting the toughness of special steel?

- The main factors affecting the toughness of special steel include its chemical composition, heat treatment process, and microstructure. The chemical composition determines the presence of alloying elements that can enhance toughness, such as nickel, chromium, and molybdenum. The heat treatment process, including quenching and tempering, can alter the microstructure of the steel, influencing its toughness. A fine and uniform microstructure with a controlled distribution of phases can enhance toughness. Additionally, factors like grain size, inclusion content, and the presence of residual stress can also impact the toughness of special steel.

- Q: What are the specific requirements for special steel used in the textile machinery industry?

- The specific requirements for special steel used in the textile machinery industry include high strength and durability to withstand the high-speed operations and repetitive movements of the machinery. The steel should also possess excellent wear resistance to prevent premature wear and tear. Additionally, it should have good corrosion resistance to withstand exposure to moisture and chemicals commonly found in textile processing. Lastly, the steel should exhibit good heat resistance to maintain its structural integrity even under high temperatures generated during the production process.

- Q: What are the safety measures taken during the production of special steel?

- During the production of special steel, several safety measures are taken to ensure the wellbeing of workers and to minimize potential hazards. These safety measures include: 1. Personal Protective Equipment (PPE): All workers involved in the production of special steel are required to wear appropriate PPE, such as safety helmets, goggles, gloves, and protective clothing. This helps protect them from potential injuries, burns, or exposure to hazardous materials. 2. Training and Education: Workers undergo thorough training and education on safe working practices and procedures. They learn about the potential hazards associated with the production of special steel and are trained on how to handle equipment and materials safely. 3. Risk Assessments: Regular risk assessments are conducted to identify potential hazards and assess the level of risk associated with each task. This allows for the implementation of control measures to mitigate risks and prevent accidents. 4. Machinery and Equipment Safety: All machinery and equipment used in the production process are properly maintained and regularly inspected to ensure they are in good working condition. Safety features, such as emergency stop buttons and guards, are in place to prevent accidents and injuries. 5. Ventilation and Exhaust Systems: Special steel production often involves high temperatures and the use of chemicals that may release harmful fumes or gases. Proper ventilation and exhaust systems are installed to remove these pollutants from the work environment, ensuring a safe and healthy atmosphere for workers. 6. Fire Prevention: Fire prevention measures, such as the installation of fire alarms, extinguishers, and sprinkler systems, are implemented to minimize the risk of fire accidents. Workers are also trained on fire safety protocols and evacuation procedures. 7. Emergency Response Plans: Comprehensive emergency response plans are developed and communicated to all workers. These plans outline procedures to be followed in case of accidents, fires, or other emergencies, ensuring a prompt and organized response. 8. Regular Safety Inspections: Regular inspections are conducted by safety professionals to identify any potential safety hazards or non-compliance with safety protocols. Any issues or deficiencies are promptly addressed to maintain a safe working environment. By implementing these safety measures, the production of special steel can be carried out in a controlled and safe manner, protecting the workers and minimizing the risk of accidents or injuries.

- Q: How does special steel contribute to the electronics aftermarket industry?

- The electronics aftermarket industry greatly relies on special steel, which is crucial for producing high-performance materials necessary for various electronic components. It offers several contributions to the industry: 1. Durability and reliability: Special steel alloys possess exceptional strength, hardness, and resistance to wear and corrosion. This makes them ideal for manufacturing electronic parts that can withstand harsh operating conditions, ensuring the longevity and reliability of electronic devices, which is a vital requirement for the aftermarket industry. 2. Heat dissipation: Many electronic devices generate significant heat while in operation, which can negatively impact their performance and lifespan. Special steel alloys with excellent thermal conductivity properties enable efficient heat dissipation, preventing overheating and enhancing the overall performance of electronic components. 3. Precision manufacturing: Special steel alloys, such as stainless steel, can be precisely machined, allowing for the production of intricate and complex electronic parts. This is particularly important for the aftermarket industry, which often involves replacing or repairing specific components in electronic devices. 4. Electromagnetic shielding: Special steel alloys are useful for creating electromagnetic shielding, which is crucial in preventing interference and maintaining the integrity of electronic signals. This is especially significant for sensitive electronic equipment that may be affected by external electromagnetic fields. 5. Customization and adaptability: Special steel can be tailored to meet the specific requirements of electronic devices, facilitating the production of custom-made components. This versatility enables manufacturers in the electronics aftermarket industry to develop and offer a wide range of specialized products that cater to diverse consumer needs and preferences. In conclusion, special steel plays a significant role in the electronics aftermarket industry, providing durable, reliable, and high-performance materials necessary for manufacturing electronic components. Its unique properties enable the production of long-lasting and efficient devices, while also allowing for customization and adaptability to meet the ever-changing demands of the market.

- Q: What are the applications of special steel in the power generation manufacturing process?

- Special steel has various applications in the power generation manufacturing process. It is commonly used in the construction of turbines, boilers, and other critical components. The high strength and heat-resistant properties of special steel make it suitable for withstanding extreme conditions and ensuring efficiency and reliability in power generation. Additionally, special steel is used in the manufacturing of transmission lines, transformers, and electrical equipment, as it provides excellent conductivity and resistance to corrosion. Overall, special steel plays a crucial role in enhancing the performance and longevity of power generation systems.

- Q: What are the applications of special steel in the manufacturing industry?

- Special steel has a wide range of applications in the manufacturing industry, including the production of machinery, tools, and equipment. It is commonly used in automotive manufacturing, aerospace engineering, and construction projects. Special steel's high strength, durability, and resistance to corrosion make it suitable for critical components requiring reliability and longevity. Additionally, its ability to withstand extreme temperatures and pressure makes it an ideal material for manufacturing specialized parts in various industries.

- Q: How does special steel perform in terms of high-temperature strength?

- Special steel is known for its exceptional high-temperature strength. It exhibits excellent resistance to deformation, creep, and thermal fatigue, allowing it to maintain its structural integrity and mechanical properties even under extreme heat conditions. This makes special steel a reliable choice for applications that require resistance to high temperatures, such as in aerospace, power generation, and industrial furnaces.

- Q: What are the different types of spring steel?

- There are several types of spring steel, including high carbon spring steel, alloy spring steel, stainless steel, and blue tempered spring steel. Each type has different properties and is used for various applications in industries such as automotive, construction, and manufacturing.

Send your message to us

ASTM A516 Grade 70 Pressure Vessel Steel Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords