Anti-Ageing FRP Pultrusion Profiles - Pultruded Gratings and Pultrusion Process

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

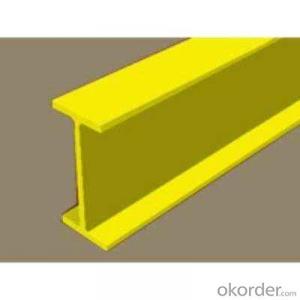

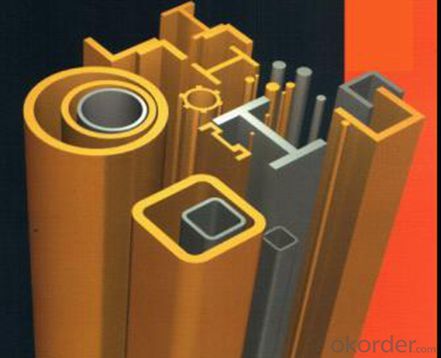

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin, VE resin, Phenolic resin

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

PACKAGING & DELIVERY

1.Packaging Details:

standard packing or your requirement

2.Delivery Detail:

Shipped in 30 days after payment

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

PICTURES

- Q: Can FRP pultrusion profiles be used in the construction of outdoor signage?

- Certainly, outdoor signage can utilize FRP pultrusion profiles. These profiles possess remarkable qualities, including durability, strength, and the ability to withstand different environmental conditions, rendering them ideal for outdoor use. Typically, these profiles consist of a combination of fiberglass reinforcement and resin matrix, resulting in a lightweight yet robust material. Outdoor signage often confronts harsh weather conditions, such as rain, sun exposure, and temperature fluctuations. FRP pultrusion profiles exhibit excellent resistance to corrosion, UV rays, and moisture, ensuring that the signage retains its structural integrity and visual appeal over time. Moreover, FRP pultrusion profiles offer customization options to fulfill specific design requirements, offering flexibility in creating distinctive and captivating outdoor signage. These profiles can be effortlessly shaped, cut, and assembled, making them a versatile choice for signage applications. In essence, the construction of outdoor signage can undoubtedly benefit from the use of FRP pultrusion profiles due to their durability, resistance to environmental conditions, and design flexibility.

- Q: Are FRP pultrusion profiles resistant to oil and grease?

- FRP pultrusion profiles are widely recognized for their exceptional ability to withstand oil and grease. The combination of fibers, typically glass or carbon, with a polymer resin matrix creates a material that is naturally resistant to numerous chemicals, including oil and grease. This resistance can be attributed to the non-reactive nature of the polymer resin, which prevents oil or grease from infiltrating the material and causing harm. Moreover, the pultrusion manufacturing process further enhances the profiles' resistance to oil and grease. In this process, the fibers are soaked in the resin and then drawn through a heated die, where the resin solidifies. This results in a sturdy, uniform material with a compact surface that is less porous and more capable of resisting chemical penetration. It is important to acknowledge that the specific resistance of FRP pultrusion profiles to oil and grease can vary depending on the resin used and the conditions of the application. In certain instances, specialized resin formulations can be employed to augment the profiles' oil and grease resistance, ensuring suitability for even the most demanding environments. Overall, FRP pultrusion profiles are widely regarded as highly resistant to oil and grease, making them an exceptional choice for applications exposed to these substances. However, it is always advisable to consult with the manufacturer or supplier to confirm that the specific FRP profile being utilized is suitable for the intended application and chemical exposure.

- Q: Are FRP pultrusion profiles resistant to electrical arcing?

- Yes, FRP pultrusion profiles are highly resistant to electrical arcing due to their non-conductive nature, making them a safe choice for applications where electrical arcing is a concern.

- Q: Are FRP pultrusion profiles UV resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are typically UV resistant. This is because they are manufactured using a combination of polymer resin and reinforced fibers such as fiberglass. These materials have inherent UV resistant properties, making FRP pultrusion profiles resistant to damage caused by prolonged exposure to sunlight and ultraviolet radiation. UV resistance is a crucial characteristic for outdoor applications where the profiles will be exposed to sunlight, such as in construction, infrastructure, and marine industries. However, it is important to note that the level of UV resistance may vary depending on the specific resin and fiber composition used in the manufacturing process. Therefore, it is recommended to consult the manufacturer or supplier for specific information on the UV resistance of FRP pultrusion profiles for a particular application.

- Q: Are FRP pultrusion profiles resistant to electromagnetic interference?

- FRP pultrusion profiles are known for their resistance to electromagnetic interference (EMI). By using fiberglass reinforced plastic (FRP) in pultrusion profiles, they offer exceptional electrical insulation properties that effectively minimize the impact of electromagnetic interference. Unlike conductive metals, FRP materials possess high dielectric strength and low electrical conductivity. As a result, FRP pultrusion profiles are less vulnerable to EMI and can serve as barriers against electromagnetic waves. Moreover, if necessary, additional layers or coatings can be applied to enhance the EMI shielding effectiveness of FRP materials. In conclusion, for applications where resistance to electromagnetic interference is crucial, FRP pultrusion profiles are a dependable choice.

- Q: Are FRP pultrusion profiles impact resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high impact resistance. The combination of strong reinforcing fibers and a polymer matrix makes them highly durable and able to withstand significant impact forces without breaking or deforming.

- Q: Can FRP pultrusion profiles be used in the oil and gas industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the oil and gas industry. These profiles offer excellent corrosion resistance, high strength-to-weight ratio, and low maintenance requirements, making them suitable for various applications in the industry such as pipe supports, cable trays, handrails, and platforms. Additionally, FRP pultrusion profiles are non-conductive, non-magnetic, and possess good fire-retardant properties, making them a safer alternative to traditional materials in hazardous environments.

- Q: Can FRP pultrusion profiles be used in chemical storage tanks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in chemical storage tanks. FRP pultrusion profiles are known for their excellent corrosion resistance, making them suitable for storing a wide range of chemicals. They are also lightweight, strong, and have a high strength-to-weight ratio, which makes them an ideal choice for constructing durable and long-lasting chemical storage tanks. Additionally, FRP pultrusion profiles can be customized to meet specific design requirements, allowing for flexibility in tank design and construction. Overall, FRP pultrusion profiles are a reliable and cost-effective option for chemical storage tanks due to their corrosion resistance, strength, and customization capabilities.

- Q: Can FRP pultrusion profiles be used in the construction of agricultural structures?

- Yes, FRP pultrusion profiles can be used in the construction of agricultural structures. FRP pultrusion profiles are lightweight, durable, and resistant to corrosion, making them suitable for various agricultural applications such as greenhouse framing, livestock enclosures, and storage sheds. They offer excellent strength-to-weight ratio and can withstand harsh environmental conditions, making them a reliable choice for agricultural construction.

- Q: Can FRP pultrusion profiles be used in the renewable energy and solar power industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the renewable energy and solar power industry. These profiles offer several advantages such as high strength, durability, corrosion resistance, and lightweight properties, making them suitable for various applications in the industry. FRP pultrusion profiles can be used for structural components, support structures, mounting systems, and other applications in solar panels, wind turbines, wave energy devices, and other renewable energy systems.

Send your message to us

Anti-Ageing FRP Pultrusion Profiles - Pultruded Gratings and Pultrusion Process

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords