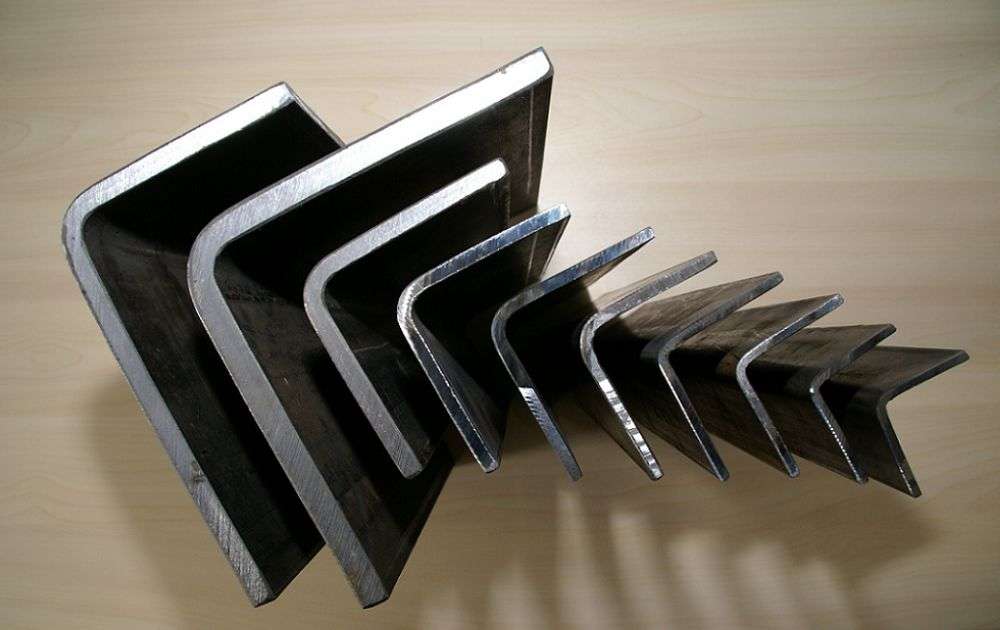

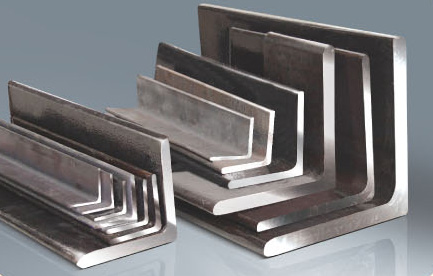

Angle Steel for Ship, Vessels and Other Steel Structures Building ASTM A276

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1)Standard:JIS AISI ASTM GB

2)Size: 25x25x3-100x100x10

3)Specification: as customers' requests.

Type | Stainless Steel Angle Bar |

Grade | AISI/SUS 201 202 301 302 303 304 304L 310 321 316 316L 410 420 430 |

Surface | Pickling, Sand Blasting |

Size | 25x25x3-100x100x10 |

Finished | Hot Rolled, Pickled, Sand Blasted |

Packing | Standard export packing, or as per customer's requests |

Payment | T/T, L/C, etc. |

Trade Terms | FOB/CFR/CIFetc. |

Stainless Steel Bar:

1.SS Angle Bar

*SS Equilateral Angle Bar

Specification:

Length: Standard length is 4m, 5m, 6m, length tolerance≤+ 40mm/pcs.

Shape: right angle tolerance is 2°

Surface: pickled or sand blasting.

2.SS Square Bar

*SS Cold Drawn Square Bar

*SS Hot Rolled & Pickled Square Bar

Specification:

Size: 12-180mm

Length:1-6mm

Surface: pickled&brushed

3.SS Hexagon Bar

*SS Cold Drawn Hexagon Bar

*SS Hot Rolled Hexagon Bar

Specification:

Diameter: 1.0-250mm

Length:1-6mm

Surface: bright

4.SS Flat Bar

*SS Hot Rolled & Pickled Flat Bar

*SS Drawn Flat Bar

Specification:

Thickness: from 3mm to 20mm

Width: from 19mm to 200mm

Length: 1-6Mm

Surface: pickled&brushed

OUR ADVANTAGES:

Our company is high quality supplier in China(mainland) with good reputation.

To develop the foreign markets, we provide customers high-quality stainless steel products with a competitive price, thoughtful after-sale service, excellent experience and import-export business skill.

Any questions, please feel free to contact with me!

- Q: How do steel angles perform in high-humidity environments?

- Steel angles perform well in high-humidity environments due to their corrosion-resistant properties. The presence of moisture in the air can often lead to rust and corrosion of metals, but steel angles are designed to withstand these conditions. They are typically made from stainless steel or galvanized steel, both of which have a protective layer that prevents rust formation. This makes them highly suitable for use in areas with high humidity, such as coastal regions or industrial settings where moisture is prevalent. Additionally, steel angles are durable and have a long lifespan, further enhancing their performance in high-humidity environments.

- Q: How do steel angles perform in terms of electrical conductivity?

- Because steel angles are made of steel, their electrical conductivity is typically poor. Steel, compared to materials like copper or aluminum, is a poor conductor of electricity. This is because the steel material has high resistance, which hinders the flow of electrons. As a result, steel angles are not frequently utilized in electrical applications that necessitate good electrical conductivity. Nevertheless, steel angles can still find utility in specific electrical applications where conductivity is not a crucial factor, such as offering structural support in electrical installations.

- Q: Can steel angles be used for decorative purposes?

- Yes, steel angles can definitely be used for decorative purposes. Steel angles are versatile and can be shaped and formed into various designs and patterns, making them a popular choice for adding a decorative touch to interior and exterior spaces. They can be used to create decorative accents such as trim, frames, and brackets. Additionally, steel angles can be easily painted or powder-coated in different colors to match any desired aesthetic. The durability and strength of steel angles also ensure that they will withstand the test of time, making them a practical and attractive option for decorative applications.

- Q: Angle iron specifications 125 * 80 * 101 m multiple

- Angle steel is a kind of carbon structural steel for construction. It is a simple section steel, mainly used in the frame of metal component and workshop. In use, better weldability, plastic deformation and mechanical strength are required. The raw steel billet for producing angle steel is low carbon square billet, and the finished product angle iron is made by hot rolling, normalizing or hot rolling.

- Q: What are the different types of steel angles used in material handling equipment?

- There are several types of steel angles commonly used in material handling equipment, including equal angles, unequal angles, and L-shaped angles.

- Q: What are the different test methods used to evaluate steel angles?

- There are several test methods used to evaluate steel angles in order to ensure their quality and suitability for various applications. These test methods include: 1. Tensile Test: This test measures the tensile strength, yield strength, and elongation properties of the steel angles. It involves applying a gradually increasing load to a specimen until it reaches its breaking point, allowing for assessment of the material's ability to resist forces without deforming or breaking. 2. Bend Test: The bend test evaluates the flexibility and ductility of steel angles. A specimen is bent to a specific angle and assessed for any signs of cracking, fracture, or deformation. This test is crucial in determining the angles' ability to withstand bending forces without compromising their structural integrity. 3. Charpy Impact Test: This test measures the impact resistance and toughness of steel angles by subjecting a notched specimen to a high-velocity impact. The amount of energy absorbed during the impact is measured, indicating the material's ability to resist sudden loads or shocks. 4. Hardness Test: The hardness test determines the steel angle's resistance to indentation or scratching. Different methods such as Rockwell, Brinell, or Vickers hardness tests may be employed to evaluate the material's hardness properties, which can help assess its durability and wear resistance. 5. Ultrasonic Testing: Ultrasonic testing uses high-frequency sound waves to detect flaws or defects within the steel angles. This non-destructive test method allows for the identification of internal cracks, voids, or inclusions that may affect the material's structural integrity. 6. Dimensional Inspection: This test method involves measuring the dimensions, tolerances, and geometric properties of the steel angles. It ensures that the angles meet the required specifications and can provide accurate information for engineering calculations and fabrication processes. By utilizing these various test methods, manufacturers, engineers, and quality control personnel can assess the mechanical properties, structural integrity, and overall quality of steel angles, ensuring their suitability for specific applications.

- Q: What are the different types of steel angle profiles?

- There are several different types of steel angle profiles, each with its own unique characteristics and applications. Some of the most common types include: 1. Equal angle: This type of steel angle has equal sides and is typically used for structural purposes, such as supporting beams or framing. It provides equal strength and stability in both directions and is often used in construction and manufacturing industries. 2. Unequal angle: As the name suggests, this type of steel angle has unequal sides. It is commonly used in applications where more strength is required in one direction, such as supporting shelves or bracing components. Unequal angle profiles are also used in the construction of bridges and buildings. 3. L-shaped angle: This type of steel angle has one side that is longer than the other, forming an L shape. It is commonly used as a support or bracket in various applications, including furniture manufacturing, automotive industry, and construction. 4. Slotted angle: Slotted angle profiles have holes or slots along the length of the angle, allowing for easy attachment and adjustment of components. They are often used in shelving units, workbenches, and storage systems, providing flexibility and versatility in design. 5. Stainless steel angle: Stainless steel angles are made from corrosion-resistant steel, making them suitable for applications in environments where moisture and harsh chemicals are present. They are commonly used in food processing, pharmaceutical, and chemical industries. 6. Galvanized angle: Galvanized steel angles are coated with a protective layer of zinc, which helps prevent corrosion and rusting. They are widely used in outdoor applications, such as fencing, signposts, and support structures, where exposure to weather elements is a concern. These are just a few examples of the different types of steel angle profiles available, each offering specific advantages and applications depending on the project requirements.

- Q: Can steel angles be used in the construction of railway bridges?

- Certainly! Railway bridges can indeed incorporate steel angles into their construction. Steel angles possess great versatility as structural elements and can serve multiple purposes, including bridge construction. They are frequently employed in the manufacturing of bridge girders, braces, and supports. Thanks to their exceptional strength and ability to bear heavy loads, steel angles are ideal for railway bridges that demand robust structural integrity and longevity. Moreover, the ease with which steel angles can be welded, bolted, or riveted together facilitates efficient and cost-effective construction methods. Ultimately, steel angles represent a viable and frequently utilized component in the construction of railway bridges.

- Q: Can steel angles be used for support beams in warehouse construction?

- Yes, steel angles can be used for support beams in warehouse construction. Steel angles are commonly used in construction for their strength and load-bearing capabilities. They provide structural support and stability, making them suitable for supporting heavy loads in warehouse buildings.

- Q: What are the considerations for selecting the appropriate steel angle thickness?

- When selecting the appropriate steel angle thickness, there are several considerations to take into account. 1. Structural requirements: The first and most important consideration is the structural requirements of the project. This includes the load-bearing capacity, support requirements, and any specific design codes or standards that need to be followed. The steel angle thickness should be chosen in a way that ensures the structural integrity of the project. 2. Application: The application of the steel angle also plays a significant role in determining the appropriate thickness. Different applications have different demands in terms of strength, durability, and resistance to environmental factors. For example, if the steel angle is intended to be used in a corrosive environment, a thicker thickness may be required to provide better protection against corrosion. 3. Cost-effectiveness: Cost is always an important consideration in any construction project. While thicker steel angles may offer greater strength and stability, they can also be more expensive. It is essential to strike a balance between the required strength and the available budget to ensure cost-effectiveness. 4. Manufacturing and fabrication limitations: The selected steel angle thickness should be within the manufacturing and fabrication capabilities of the manufacturer. It is crucial to consider the availability of the desired thickness and the feasibility of producing the required dimensions. 5. Aesthetic considerations: In some cases, the appearance of the steel angle may be a factor to consider. Thicker angles may have a more substantial and visually appealing look, which can be desirable in certain architectural or design applications. 6. Availability and standard sizes: Availability of steel angles in different thicknesses and standard sizes can also influence the selection process. It is often more convenient and cost-effective to choose a thickness that is readily available in the market. In conclusion, selecting the appropriate steel angle thickness requires careful consideration of structural requirements, application demands, cost-effectiveness, manufacturing limitations, aesthetic preferences, and the availability of standard sizes. By taking all these factors into account, one can make an informed decision that meets the project's needs and ensures the desired level of strength and durability.

Send your message to us

Angle Steel for Ship, Vessels and Other Steel Structures Building ASTM A276

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords