Aluminum Trailer Skin Sheets in Different Corrugation Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

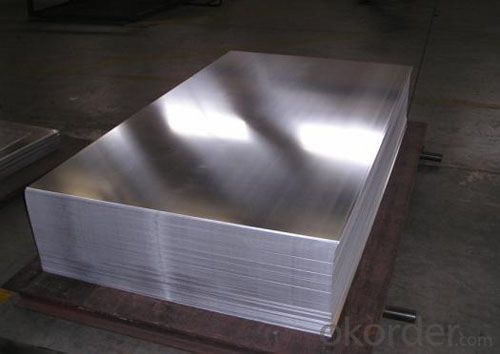

Corrugated Aluminum Sheet in Different Corrugation Profiles

Specifications

Alloy NO. | Thickness | Width | Length | Production line | Circulation size |

1050 1060 1100 3003 | 0.3-9.5mm | 800--2200mm | 1000--10000mm | DC,CC | 1220*2440mm 1250*2500mm 1500*3000mm 1000*2000mm

|

5052 5083 5454 5754 5086 | 0.5-150mm | 800--2200mm | 1000--6000mm | DC | |

6061 | 5-150mm | 800--2200mm | 1000--10000mm | DC | |

7075 | 6-150mm | 800--2200mm | 1000--10000mm | DC | |

Packing | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | ||||

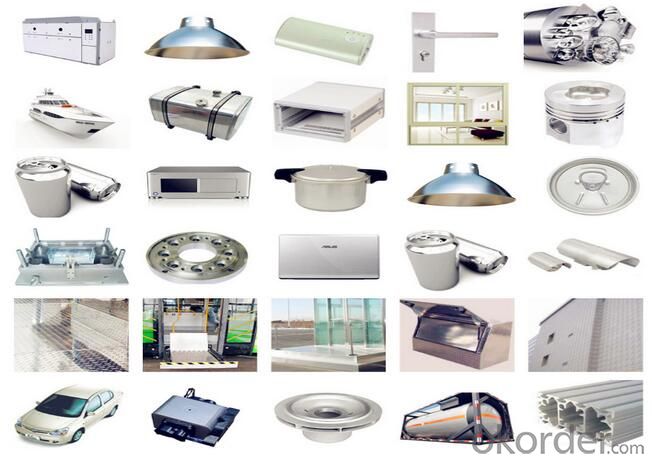

Application | decoration:ceilings,walls,furniture,cabinets,elevators,signs,name plate, transportation, cookware, household appliances:refrigerators,microwave ovens, machinery, mold making,aerospace and military aspects, auto, PP cap , construction etc | ||||

Standard | Chemical Composite: GB/T 3190-2008, JIS, EN, ASTM | ||||

Mechanical Property: GB/T 3880.2-2012, JIS, EN, ASTM | |||||

MOQ | 5TONS | ||||

Kind attention | Specifications can be customized as the customer’s requirements | ||||

Application

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons.

- Q: What is the tensile strength of aluminum?

- The tensile strength of aluminum varies depending on the specific alloy and temper, as well as the manufacturing process. However, on average, the tensile strength of aluminum ranges from around 70 to 700 MPa (megapascals). This makes aluminum a relatively strong material compared to other non-ferrous metals. It is important to note that the tensile strength can also be influenced by factors such as the thickness and shape of the aluminum component, as well as any heat treatment it has undergone. Therefore, it is always recommended to consult specific data sheets or engineering references for accurate and precise information regarding the tensile strength of a particular aluminum alloy.

- Q: How do I prevent corrosion on aluminum sheets?

- To prevent corrosion on aluminum sheets, several steps can be taken: 1. Regularly clean the aluminum sheets using a mild detergent or aluminum cleaner to eliminate any dirt, grime, or chemical residues present on the surface. This will prevent the accumulation of corrosive substances. 2. It is worth considering the application of a protective coating on the aluminum sheets. There are different types of coatings available, such as clear coats, anodizing, or painting. These coatings act as a barrier between the aluminum and the surrounding environment, effectively preventing corrosion. 3. Take care to avoid contact with corrosive substances. Aluminum can be susceptible to corrosion when exposed to certain chemicals like acids, alkalis, or saltwater. Be mindful of the environment in which the aluminum sheets are stored or utilized and steer clear of exposure to these corrosive substances. 4. Store the aluminum sheets in a dry environment with low humidity levels. Moisture can accelerate the corrosion process, so it is crucial to keep the sheets dry and protected from excessive moisture. 5. Consider implementing preventive measures such as using corrosion inhibitors or anti-corrosion sprays specifically designed for aluminum. These products can provide an additional layer of protection against corrosion, particularly in harsh or corrosive environments. By adhering to these preventive measures, the risk of corrosion on aluminum sheets can be significantly reduced, effectively extending their lifespan.

- Q: What are the colors of iron sheet and aluminum sheet?

- they are both silver white.

- Q: What is the cost of aluminum sheets?

- The cost of aluminum sheets can vary depending on various factors such as the thickness, size, and grade of the aluminum. Additionally, market conditions and supplier pricing policies can also influence the cost. It is recommended to contact local suppliers or search online to get the most accurate and up-to-date pricing information for aluminum sheets.

- Q: I am looking at buying a used 1983-84 Eldorado but have read some things about the reliability of the aluminum engine. Any thoughts? Thanks.

- aluminum engines are used to save weight and help increase horsepower, I don't think that making an engine from aluminum is a bad thing, the biggest problem is making sure you NEVER EVER OVERHEAT IT. They use steel sleeves in the piston bores and other critical high stress areas, but the biggest problem is once overheated its done, vaporized aluminum is actually very explosive too, Any Eldorado's still around from 84 now, I think has a good engine in it. another potential problem is spark plug removal and installation, using an anti seize is recommended. If you do find an Eldorado's now, someone may have installed a iron block in it anyway, because one thing aluminum motors are known for, is being very expensive.

- Q: What are aluminum sheets?

- Aluminum sheets are thin flat pieces of aluminum that are commonly used in various industries for applications such as construction, automotive manufacturing, packaging, and aerospace. They are versatile, lightweight, and durable, making them ideal for a wide range of purposes.

- Q: What is the lifespan of the aluminum sheets?

- The lifespan of aluminum sheets can vary depending on several factors such as the quality of the aluminum, the environment in which they are used, and the level of maintenance they receive. However, aluminum sheets are known for their durability and longevity. On average, aluminum sheets can last anywhere from 20 to 30 years, but with proper care and maintenance, they can even exceed this lifespan. Regular cleaning, protection from harsh weather conditions, and avoiding exposure to corrosive substances can all contribute to extending the lifespan of aluminum sheets.

- Q: What is the cost of an aluminum sheet?

- The cost of an aluminum sheet can vary depending on factors such as size, thickness, and quality. It is recommended to check with suppliers or conduct market research to get accurate and up-to-date pricing information.

- Q: does anyone know how aluminum recycling works in term of redox reaction ( oxidizing, reduced, oxidizing agent, reducing agent?). how is that relate to the process of electrochemistry?

- Aluminum recycling is done by just melting the cans back into molten metal. There are reactions, but those deal with the impurities, not the aluminum. See the reference.

- Q: Alumina is the protective coating that covers aluminum when exposed to oxygen. It's actually corroded aluminum that prevents the aluminum from continuously corroding.What I didn't know until recently was that alumina is an electrical insulator. If that's the case why then isn't aluminum an insulator if one is trying to pass current along its surface?

- Aluminum is an efficient conductor of electricity. A usual fabric that is not conductive is glass but glass will habits heat. Wood isn't warmth conductive or an electricity conductor however has a low combustion factor. You probably have a specific utility you are watching for then you definitely'd better ask extra certain questions.

Send your message to us

Aluminum Trailer Skin Sheets in Different Corrugation Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords