Aluminum Sheet Price Factory and Best Quality in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Sheet Price Factory and Best Quality in China

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

2. Application of Aluminum Sheet Price Factory and Best Quality in China

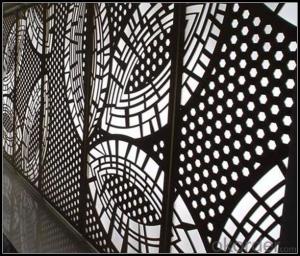

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

Feature of Aluminum Sheet Price Factory and Best Quality in China

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

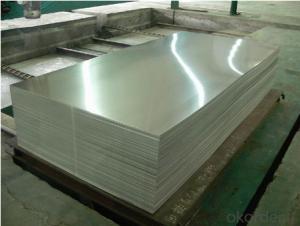

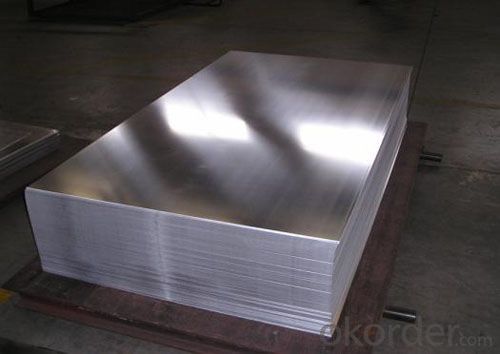

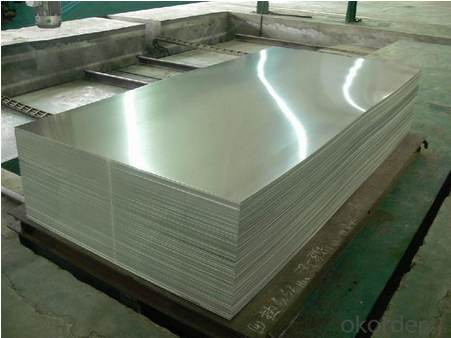

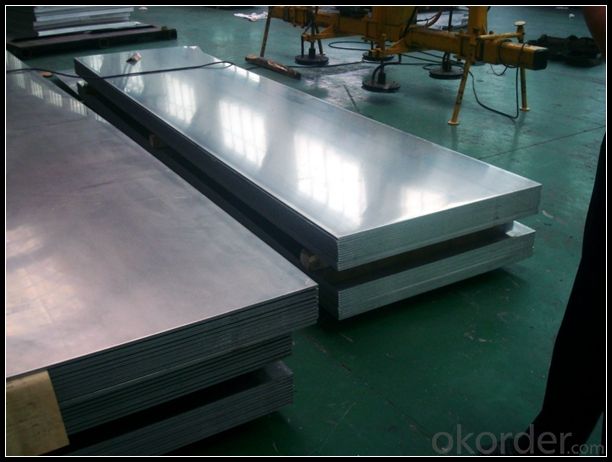

5. Image of Aluminum Sheet Price Factory and Best Quality in China

6. Package and shipping of Aluminum Sheet Price Factory and Best Quality in China

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

Steel or Aluminium Fabrication - Which Is the Better Option for You?

You need custom fabricated application for your business or home. There are many important decisions which you have to make in order to get the best solution from the professional contractor that you have chosen. One of them is which metal will be most suitable for your needs. The main options which you have available are two - steel and aluminium fabrication. Find out how the two compare to make the right decision.

The Two Metals Compared

How suitable is each of the two materials for sheet metal fabrication? Aluminium is generally more malleable. This means that it can be fabricated into more intricate shapes. Similarly, smaller components can be made from it as well. Still, most of the applications required by business and households such as platforms and ductwork are fairly large and have basic shapes.

Steel is certainly the stronger of the two metals. It is less likely to get bent, deformed or dented when it is exposed to great weight, force or heat. At the same time, the strength of the other metal can be increased as well. This is done through its mixing with copper and magnesium for producing alloys.

Aluminium is resistant to corrosion and this is its major advantage. It is suitable for all kinds of outdoor applications and for ones which are designed to be in contact with liquids or moisture. Steel can be made more resistance to corrosion as well. This is done through the application of protective metal coatings via specific processes such as galvanization.

Individual Requirements

Both metals have their own benefits and advantages. That is why the best way to choose between aluminium and steel fabrication is to consider the application which you require, where it will be set up and how it will be used. This will help you to make the final decision.

The first thing which you need to check is whether there are any specific standards and legal requirements which the application has to meet. For example, facilities which are used for the production and serving of foods and beverages typically need to be made from stainless steel as this material is hygienic and does not have any impact on their taste.

You also need to take into account the kind of weight which the application will bear. This is extremely important in the case of platforms, walkways, mounts, ladders and truck trailers. You have to check whether the application will be exposed to moisture especially in the case of ductwork and piping.

- Q: What is the density of aluminum plate?

- Aluminum density and structure:The density of aluminum is about 2.7, about 1/3 of the average metal, and the conductivity of common aluminum conductors is about 61% of copper and half of that of heat. Although pure aluminum is very soft and malleable, it can still be hardened by cold working and by alloy. Bauxite is an important source of aluminum. It takes about two pounds of bauxite to make a pound of alumina, and two pounds of alumina is needed to make a pound of aluminum

- Q: Are aluminum sheets suitable for laser cutting?

- Yes, aluminum sheets are suitable for laser cutting.

- Q: Solid aluminum or solid wooden boxes-no glass top. Would glass make the temperature rise more quickly? (ie Solar)? Thanks.Joseph

- Aluminum is a very good conductor of heat and wood is a very poor conductor of heat. If the heat source is inside the box with the food, it will heat quicker in a wooden box. If the heat source is outside the box it will heat quicker in an aluminum box. Having a glass top would be equivalent to having the heat inside the box so a wood box with a glass top will make a better solar heater.

- Q: what's the difference between zinc sheet and aluminum sheet?

- Only zinc sheet can react, zinc is amphoteric.

- Q: Are aluminum sheets resistant to impact?

- Yes, aluminum sheets are generally resistant to impact. Aluminum is a lightweight metal that has high strength and toughness, making it capable of withstanding impact forces. It has excellent energy absorption properties, which means it can absorb and dissipate the energy generated by an impact, minimizing damage to the sheet. Additionally, aluminum sheets can be further strengthened through various processes such as heat treatment or alloying, making them even more resistant to impact. However, the impact resistance of aluminum sheets can vary depending on the specific alloy and thickness used.

- Q: Can aluminum sheets be used for heat sinks in LED lighting?

- Yes, aluminum sheets can be used for heat sinks in LED lighting. Aluminum is an excellent conductor of heat, and its high thermal conductivity makes it an ideal material for dissipating heat generated by LED lights. The use of aluminum sheets as heat sinks helps to transfer the heat away from the LED chips, preventing overheating and prolonging the lifespan of the LED lighting system. Additionally, aluminum is lightweight, corrosion-resistant, and cost-effective, making it a popular choice for heat sink applications in LED lighting.

- Q: Are aluminum sheets suitable for pharmaceutical applications?

- Yes, aluminum sheets are suitable for pharmaceutical applications. Aluminum is a widely used material in the pharmaceutical industry due to its various beneficial properties. Firstly, aluminum sheets are lightweight and have excellent corrosion resistance. This makes them ideal for packaging pharmaceutical products as they can protect the contents from external factors such as moisture, light, and oxygen, which could potentially degrade the quality of the medication. Additionally, aluminum sheets can be easily formed into different shapes and sizes, allowing for customization in packaging design. They are also available in various thicknesses, providing options for different types of pharmaceutical products, from tablets and capsules to liquid medications. Furthermore, aluminum sheets have a high barrier property, effectively preventing the transfer of odors, flavors, and contaminants. This ensures the integrity and safety of the medication throughout its shelf life. Moreover, aluminum is a non-toxic material, which means it does not react with drugs or alter their composition. This makes it a suitable choice for pharmaceutical applications, where maintaining the purity and stability of the medication is crucial. In conclusion, aluminum sheets are highly suitable for pharmaceutical applications due to their lightweight, corrosion resistance, barrier properties, and non-toxic nature. They provide efficient protection and preservation of pharmaceutical products, ensuring their quality and safety.

- Q: What are the different types of alloys used for powder-coated aluminum sheets?

- There are various types of alloys used for powder-coated aluminum sheets, including 3003, 5052, and 6061.

- Q: Can you really block thermal imaging with glass or aluminum foil? If not, what can?

- Yes you can better with aluminum foil and somewhat little with glass. Thermal imaging takes a heat image based on an object radiating out more heat than it's background. The heat is all in the infrared so does not depend on visible light Aluminum foil is very effective in radiating back infrared waves, and very little infrared will pass thru the foil. Glass will let about 90 percent come thru, but it depends on the angle of incidence, with higher angles reflecting more infra red. But Stand in front of a window with the sun shining in, and you see how much infrared from the sun you can feel on your skin . Foil is probably about 95 % effective in reflecting infrared, depending on how shiny it is. In real life situations that is why the inside of thermos bottles are shiny aluminum (or silver) to reflect infrared heat, and fireman wear aluminum suits into fires to protect from the radiant heat ,which is the infrared. So if you wore an aluminized or silverized suit , a thermal imaging device would have a hard time seeing you from the background radiation given off by other objects. You have to give off more radiant heat than surrounding objects to be noticed by a thermal camera

- Q: It seemed in my experiment that aluminum wasn't reactive at all in the displacement reactions, except with copper sulfate. Is there a reason? or did I make a mistake? aluminum is more reactive than e.g silver nitrate, why didn't it react with it?

- Aluminium has a protective coating of Aluminium Oxide, this prevents many chemicals reaching the surface. This is because aluminium has a very strong affinity for oxygen and bonds to it with extremely strong bonds. It can be removed by dipping it carefully into a solution of Mercury (II) Chloride.

Send your message to us

Aluminum Sheet Price Factory and Best Quality in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords