Aluminum Sheets in North Dakota - Best Quality Aluminum Sheet Metal Roll Prices from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

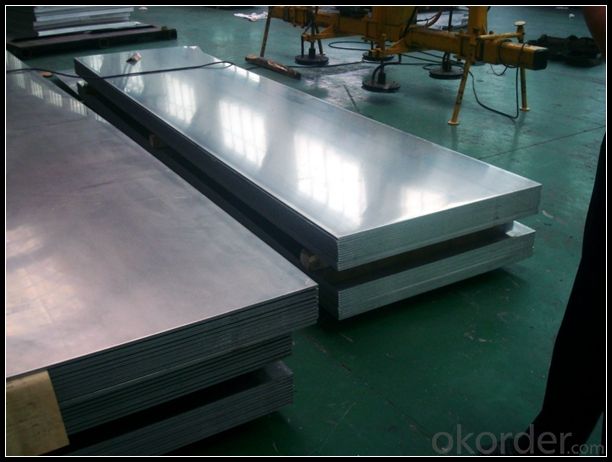

1. Specification of Aluminum Sheet Metal Roll Prices Best Quality in China

Aluminum Coil/Sheet | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

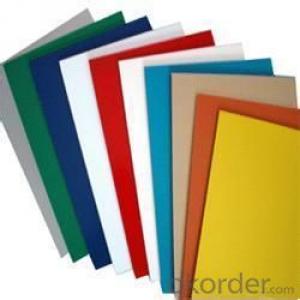

2. Application of Aluminum Sheet Metal Roll Prices Best Quality in China

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

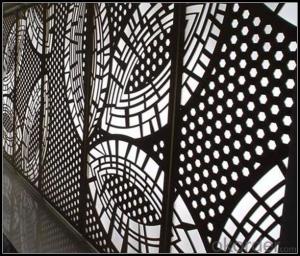

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Sheet Metal Roll Prices Best Quality in China

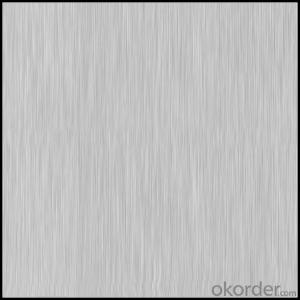

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

5. Image of Aluminum Sheet Metal Roll Prices Best Quality in China

6. Package and shipping of Aluminum Sheet Metal Roll Prices Best Quality in China

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Is it possible to utilize aluminum sheets for creating signs or banners?

- <p>Yes, you can use aluminum sheets to make signs or banners. Aluminum is a popular choice due to its durability, lightweight, and resistance to weather conditions. It can be easily cut, shaped, and printed on, making it ideal for outdoor signage. Additionally, aluminum sheets can be coated or laminated to enhance their visual appeal and protect against scratches and fading.</p>

- Q: Can 101 aluminum sheets be bent without cracking or breaking?

- No, it is highly unlikely that 101 aluminum sheets can be bent without cracking or breaking.

- Q: Are aluminum sheets suitable for signage?

- Yes, aluminum sheets are highly suitable for signage. Aluminum is a versatile material that offers a range of benefits for signage applications. It is lightweight, durable, and resistant to corrosion, making it ideal for both indoor and outdoor signage. Aluminum sheets can withstand harsh weather conditions, including rain, snow, and UV exposure, without deteriorating or fading. They are also easy to work with, allowing for a variety of customization options such as embossing, engraving, and digital printing. Moreover, aluminum sheets are cost-effective and have a long lifespan, ensuring that signage remains in excellent condition for extended periods. Overall, aluminum sheets are a popular choice for signage due to their durability, versatility, and aesthetic appeal.

- Q: Can 101 aluminum sheets be anodized for medical equipment applications?

- Yes, 101 aluminum sheets can be anodized for medical equipment applications. Anodizing is a process that enhances the corrosion resistance and durability of aluminum, making it suitable for various industries, including medical equipment.

- Q: Are 101 aluminum sheets suitable for outdoor applications?

- Indeed, outdoor applications can benefit from the suitability of 101 aluminum sheets. This alloy, widely favored, boasts exceptional resistance to corrosion, rendering it an optimal choice for outdoor settings frequently subjected to moisture, sunlight, and similar factors. Moreover, 101 aluminum exhibits solid strength and durability, enabling it to endure diverse weather conditions and physical strains. As a result, it finds extensive use in outdoor projects, including siding, roofing, gutters, and outdoor signage.

- Q: Are aluminum sheets suitable for hydraulic applications?

- Indeed, aluminum sheets prove to be fitting for hydraulic applications. Being both lightweight and resistant to corrosion, aluminum serves as a remarkable option for hydraulic systems. Its commendable thermal conductivity aids in effectively dispersing heat produced during hydraulic operations. Furthermore, aluminum sheets can be effortlessly shaped and machined to fulfill precise design needs, rendering them adaptable for an array of hydraulic components including reservoirs, tanks, and piping systems. Nevertheless, it is crucial to bear in mind the pressure and temperature prerequisites of the hydraulic application, given that aluminum possesses inferior strength and melting point in comparison to metals like steel.

- Q: How do aluminum sheets compare to steel sheets in terms of weight?

- Aluminum sheets are significantly lighter than steel sheets, as aluminum has a lower density compared to steel.

- Q: On candle when candle flame is about 1.000 degrees celsius and melting point of aluminum is 660 degrees celsius.

- Aluminium is a highly reactive metal and undergoes passivation. Thus, there is a highly non-reactive layer of Al2O3 around any piece of aluminium exposed to oxygen for any length of time. Al2O3 has a melting point of 2000+ degrees celsius, and it provides some amount of insulation to the aluminium below.

- Q: Are aluminum sheets suitable for HVAC applications?

- Aluminum sheets are indeed suitable for HVAC (Heating, Ventilation, and Air Conditioning) applications, as they possess various advantageous properties. Primarily, aluminum's lightweight nature facilitates easy handling and installation within HVAC systems, which is particularly crucial for larger systems that necessitate a substantial amount of material. Moreover, aluminum exhibits exceptional resistance to corrosion, rendering it ideal for HVAC applications that frequently encounter moisture and condensation. This corrosion resistance guarantees the longevity and durability of the HVAC system, ultimately reducing maintenance and replacement expenses in the long run. Furthermore, aluminum boasts excellent thermal conductivity, enabling efficient heat or cold air transfer throughout the HVAC system. This attribute ensures optimal heating and cooling, thereby diminishing energy consumption and resulting in cost savings for users. Furthermore, aluminum sheets can be effortlessly molded and shaped to fit specific HVAC requirements, thus allowing for customized designs and precise installation. This versatility positions aluminum as the preferred choice for components such as ductwork and heat exchangers in HVAC systems. In conclusion, aluminum sheets are highly compatible with HVAC applications due to their lightweight nature, corrosion resistance, thermal conductivity, and flexibility. These properties collectively contribute to the efficiency, durability, and performance of HVAC systems, establishing aluminum as the preferred material within the industry.

- Q: How do you clean aluminum sheets?

- To clean aluminum sheets, you can follow a few simple steps: 1. Start by removing any loose dirt or debris from the surface of the aluminum sheet. You can use a soft brush or cloth to gently sweep away any particles. 2. Prepare a cleaning solution by mixing a mild detergent or dish soap with warm water. Avoid using strong chemicals or abrasive cleaners as they can damage the aluminum. 3. Dip a soft cloth or sponge into the cleaning solution and gently scrub the aluminum sheet. Make sure to cover the entire surface, paying extra attention to any stains or spots. 4. If there are stubborn stains or marks on the aluminum, you can use a non-abrasive cleaner specifically designed for aluminum. Apply the cleaner to a soft cloth and rub gently on the affected area until the stain is removed. 5. Rinse the aluminum sheet thoroughly with clean water to remove any soap residue. This step is essential to prevent any build-up or streaks on the surface. 6. Dry the aluminum sheet completely using a soft towel or cloth. Make sure there is no moisture left as it can cause water spots or corrosion over time. 7. For added shine and protection, you can apply a thin layer of aluminum polish or wax. This will help to restore the luster and protect the aluminum from future tarnish or oxidation. It is important to note that the cleaning method may vary depending on the type of dirt or oxidation on the aluminum sheet. Always read and follow the manufacturer's instructions for specific cleaning recommendations.

Send your message to us

Aluminum Sheets in North Dakota - Best Quality Aluminum Sheet Metal Roll Prices from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords