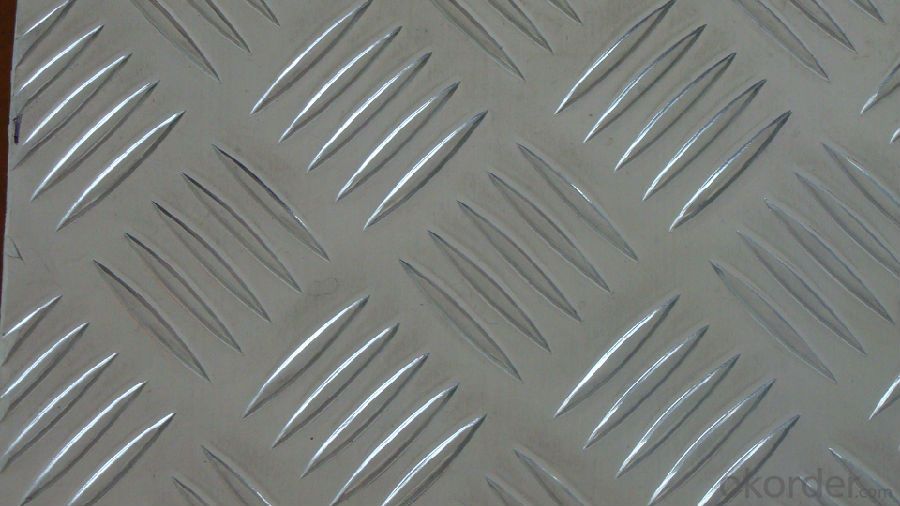

Aluminum Roofing Sheets in Georgia - 2a12 5052 5083 6061 6083 7075 Aluminum Sheet Price Per Kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Discription:

Aluminum Sheets

Alloy No.: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3104, 3105, 5005, 5052, 5083, 5754, 8011, 8006, 8079, etc..

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-20mm

Width: 10mm - 2100mm

Character:

High-temperature sterilization

Made of advanced food grade alu material,no pollution

Eco-friendly, recoverable and recyclable

Application:

widely used for food cooking, freezing wrapping, storing etc, the main application are for household and catering, which are targeting for retail market and food service market, such as hypermarket, chain store and hotel, restaurant etc.

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: do recycling centers take already compacted aluminum cans? Link is below. if not then why are so many people making homemade can crushers?

- Yes, they do. My Recycling Center accepts whole, torn-up, or compacted/crushed aluminum cans. We even accept aluminum pet-food cans. Since they are shredded to prepare them for recycling, it doesn't matter. The only time you should not compact or crush your aluminum cans is if you are using one of those automatic can-munchers that you can find in some parking lots that pays you immediately. Compacted aluminum cans will jam those machines. Aluminum can be recycled over and over, unlike other recyclables such as plastic, which can typically only be recycled once.

- Q: how many aluminum ions are present?how many chloride ions are present?what is the mass in grams of one molecule of aluminum chloride?help! i have no clue how to do this i need to know how for my quiz!!!

- You have to remember Avogadro's number: 6.02 x 10^23 Read about it in your text book. It is the number of molecules of any atom that make up 1 mole. 1 mole of a molecule is equal to it's atomic weight in grams. So, the atomic weight of aluminum is 26.9. So, 26.9 grams of aluminum contains exactly 6.02 x 10^23 molecules of aluminum (or 1 mole). What's the molecular weight of aluminum chloride? Well, 26.9 + 3(35.5) = 133.4 the 35.5 is the molecular weight of chloride and there are 3 of them. So, 133.4 grams of aluminum chloride would be 6.02 x 10^23 molecules. We only have 37.2 g. 37.2 g/ 133.4 g per mole = 0.279 moles. 0.279 moles x (6.02 x 10^23 molecules/mole) = 1.68 x 10^23 molecules of aluminum chloride. So, since there is one aluminum per molecule, you have your answer. Just multiply by three to find out how many molecules of chloride are present. Finally, if 133.4g = 6.02 x 10^23 molecules, then 1 molecule = 133.4 / 6.02x10^23 = 22.16 x 10^-23 or 2.216 x 10^-22 Make sure that the periodic table you use for class has the same values (some tables are more simplified then others). Also, make sure that you use the correct number of scientific digits when calculating your answer.

- Q: This question asks about the impact of aluminum sheets on the air quality inside a building.

- <p>Aluminum sheets themselves do not directly affect indoor air quality. They are inert materials that do not emit volatile organic compounds (VOCs) or other harmful substances. However, the installation process might involve adhesives or sealants that could release VOCs temporarily. Proper ventilation during and after installation can mitigate this issue. Additionally, aluminum sheets can contribute to better air quality by enhancing thermal performance, reducing energy consumption for heating and cooling, and indirectly lowering emissions from power plants.</p>

- Q: on the metal activity series, aluminum sits between magnesium and zinc, and all three sit above hydrogen. Explain why aluminum typically reacts only slowly with dilute acids even though both magnesium and zinc react rapidly

- Aluminum metal reacts with oxygen in the air to form a very tightly bonded aluminum oxide on its surface which slows the attack of acids trying to make contact with the aluminum atoms below the surface.

- Q: I saw a nice looking set of cast aluminum pots for a very good price. They feel very heavy. But I remember hearing that aluminum is not healthy so I am wary of buying them. Any advice would be appreciated.

- Cast Aluminum Pots

- Q: What are the different methods of surface protection for aluminum sheet?

- There are several different methods of surface protection for aluminum sheet that can be employed to enhance its durability and resistance to various external factors. One common method is anodizing, which involves creating a thick oxide layer on the surface of the aluminum through an electrochemical process. Anodizing provides corrosion resistance, improves wear resistance, and allows for color customization through the use of dyes. Another method is powder coating, where a dry powder is applied to the aluminum surface and then heated to create a durable and protective layer. Powder coating offers excellent resistance to chemicals, UV rays, and scratches, and it also provides a wide range of color options. Laminating is another technique used to protect aluminum sheets. In this method, a thin layer of protective film is applied to the surface, acting as a barrier against scratches, dirt, and moisture. Laminating is commonly used for aluminum sheets that require temporary protection during transportation or storage. Chemical conversion coating is yet another method employed to protect aluminum surfaces. This involves treating the aluminum with a chemical solution that creates a thin layer of protective coating. The coating not only enhances corrosion resistance but also improves paint adhesion. Furthermore, clear coating can be applied to aluminum sheets to provide a protective layer without altering the appearance of the metal. Clear coatings can be either solvent-based or water-based and offer resistance against corrosion, scratches, and UV rays. Lastly, mechanical finishes such as brushing or polishing can be used to protect aluminum surfaces. These finishes create a smooth and aesthetically pleasing surface while also providing some level of protection against corrosion and wear. Overall, these various methods of surface protection for aluminum sheet offer different levels of durability, corrosion resistance, and aesthetic options, depending on the specific requirements and applications.

- Q: I've heard twice in the past 2 days on ESPN that they think Aluminum bats are dangerous. I disagree with this cause if they were dangerous why would they allow them to use them in college and high school. Isnt that what the BESR certification mean that the bat is safe that the ball isnt going to come off at super high speeds. i just wanted to get your opinion.

- No they are not but they are STUPID. Has a story or poem ever had the PING of the bat? No! It's the CRACK of the bat that's what the game is all about.

- Q: What are the different types of alloys used for powder-coated aluminum sheets?

- There are several different types of alloys used for powder-coated aluminum sheets, each with its own unique set of properties and characteristics. Some of the most commonly used alloys include: 1. 3003 Alloy: This alloy is one of the most widely used for powder-coated aluminum sheets. It offers good corrosion resistance, excellent formability, and high strength. It is often used in applications that require moderate strength and resistance to atmospheric corrosion, such as building facades, signage, and automotive parts. 2. 5052 Alloy: This alloy is known for its high strength and excellent corrosion resistance. It is often used in marine and architectural applications where durability and resistance to saltwater and harsh environments are essential. It is also commonly used in the manufacturing of electrical enclosures and transportation equipment. 3. 6061 Alloy: This alloy is highly versatile and offers excellent weldability, formability, and machinability. It is often used in a wide range of applications, including aerospace components, marine hardware, structural components, and automotive parts. It has good corrosion resistance and can be easily powder-coated to enhance its appearance and provide additional protection. 4. 7075 Alloy: This alloy is known for its high strength-to-weight ratio and excellent fatigue resistance. It is commonly used in aerospace applications, such as aircraft fittings and structural components, where strength and lightweight properties are crucial. Although it is less commonly used for powder-coated aluminum sheets due to its higher cost, it can still be found in certain specialized applications. These are just a few examples of the different types of alloys used for powder-coated aluminum sheets. The choice of alloy depends on the specific requirements of the application, including factors such as strength, corrosion resistance, formability, and cost.

- Q: This question asks about the various types of adhesives that can be used to bond aluminum sheets together.

- <p>There are several types of adhesives suitable for bonding aluminum sheets together, including epoxy adhesives, which offer strong bonding and resistance to heat and chemicals; acrylic adhesives, known for their flexibility and resistance to UV light; cyanoacrylate adhesives, or super glues, which provide fast bonding but may not be as strong for heavy-duty applications; polyurethane adhesives, which are durable and flexible; and silicone adhesives, which are excellent for high-temperature applications and provide water resistance. Each type has its own advantages and is chosen based on the specific requirements of the bonding task, such as strength, flexibility, temperature resistance, and curing time.</p>

- Q: So I want to solder aluminum cans together for this project I have. What tools will I need?

- Your aluminum can's are unfortunatly too thin to solder. Your best bet for this project, is going to be a hot glue gun. Hope this helps.

Send your message to us

Aluminum Roofing Sheets in Georgia - 2a12 5052 5083 6061 6083 7075 Aluminum Sheet Price Per Kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords