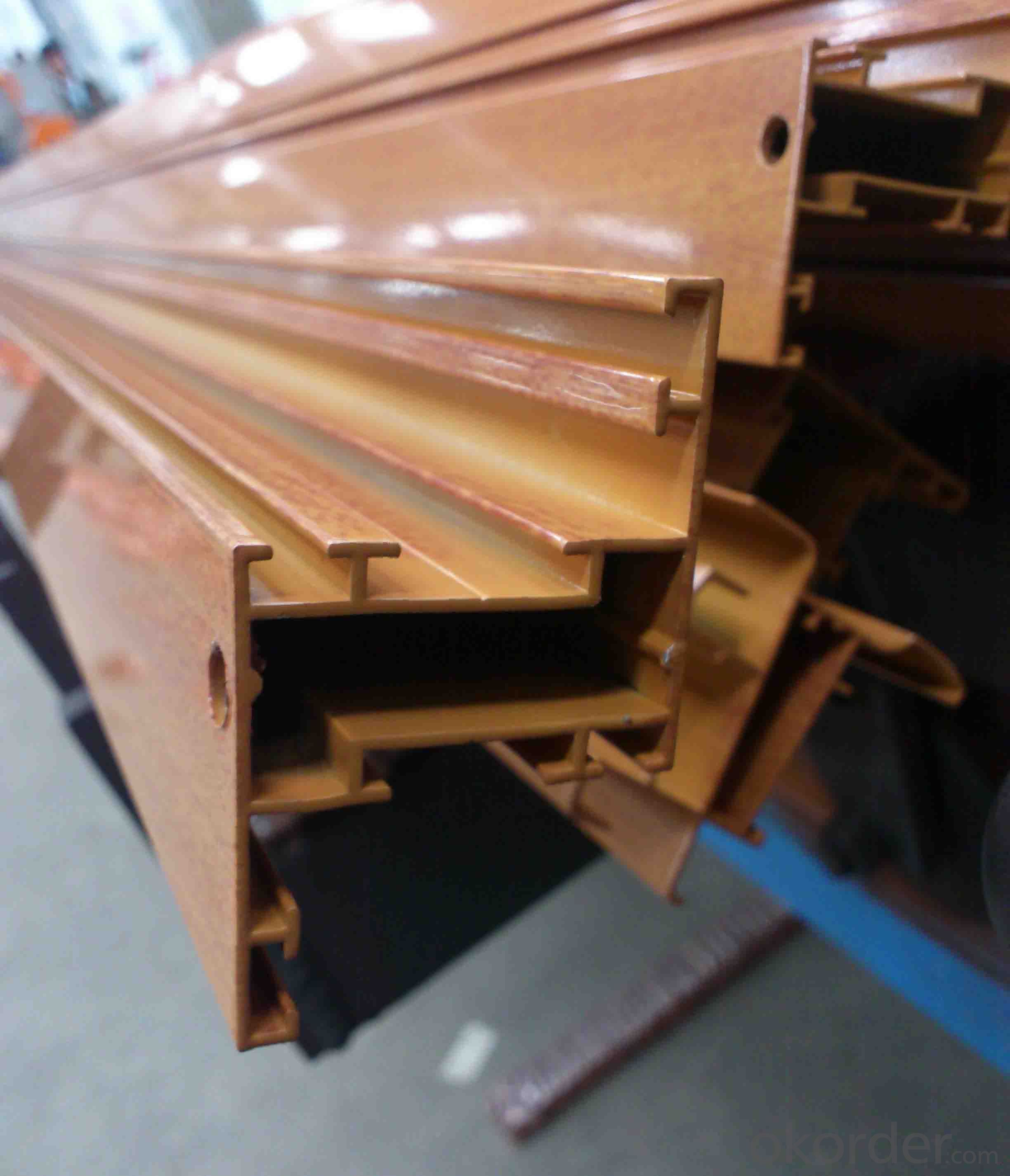

Aluminum Profiles for Africa:Windows & Doors

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Aluminium profile

we have the whole window system for Africa Market

Surface:Wood Color

Material: 6063 T5

- Q: This question asks for a method to determine the quantity of aluminum profiles required for a specific project.

- <p>To calculate the amount of aluminum profiles needed for a project, first, determine the dimensions and design of the structure. Measure the length, width, and height of the required profiles. Consider the number of profiles needed for each section of the project. Multiply the length of each profile by the number of profiles required. Sum these totals for all sections to get the overall amount of aluminum needed. Factor in a margin for cutting and waste to ensure you have enough material. Consult with suppliers or use specialized software for more precise calculations, especially for complex projects.</p>

- Q: This question asks for methods to ensure that the installation of aluminum profiles is both cost-effective and efficient.

- <p>To ensure the installation of aluminum profiles is cost-effective and efficient, follow these steps: 1) Plan carefully: Use accurate measurements and detailed plans to minimize waste and rework. 2) Use quality materials: Invest in high-quality aluminum profiles to reduce maintenance and replacement costs. 3) Employ skilled labor: Well-trained installers can complete the job faster and with fewer errors. 4) Optimize the installation process: Streamline the process to reduce time and labor costs. 5) Regular maintenance: Proper care and maintenance can extend the life of aluminum profiles, saving on replacement costs. 6) Compare suppliers: Shop around for the best prices and quality to minimize costs. 7) Use modular designs: Modular systems can be more efficient to install and easier to modify in the future.</p>

- Q: Is it possible to tailor aluminum profiles to fulfill particular design and aesthetic needs?

- <p>Yes, aluminum profiles can be customized to meet specific aesthetic requirements. Manufacturers offer a variety of finishes, colors, and surface treatments to enhance the visual appeal of aluminum profiles. Additionally, the profiles can be cut, bent, and shaped to fit unique design specifications. This customization allows for a high degree of flexibility in creating structures and designs that are both functional and visually appealing, making aluminum profiles suitable for a wide range of applications from architectural to industrial design.</p>

- Q: Can aluminum profiles be used in the construction of curtain walls?

- Yes, aluminum profiles can be used in the construction of curtain walls. In fact, aluminum is one of the most commonly used materials for curtain wall systems due to its numerous advantageous properties. Aluminum profiles are lightweight yet strong, making them ideal for creating large and structurally sound curtain walls. Additionally, aluminum is highly resistant to corrosion, ensuring the longevity and durability of the curtain wall. It is also a highly versatile material that can be easily shaped and fabricated to meet specific design requirements, allowing for the creation of unique and aesthetically pleasing curtain walls. Furthermore, aluminum profiles can easily accommodate various components and features such as glazing, insulation, and ventilation systems, making them a popular choice for modern curtain wall designs. The use of aluminum profiles also allows for efficient installation and maintenance processes, as they can be prefabricated offsite and quickly assembled on-site. Overall, the use of aluminum profiles in the construction of curtain walls offers numerous benefits in terms of strength, durability, versatility, and aesthetics, making it a preferred choice for many architects and builders in the construction industry.

- Q: Are aluminum profiles suitable for use in the renewable energy industry?

- Aluminum profiles are well-suited for the renewable energy sector, offering numerous benefits. To begin with, aluminum is a versatile and lightweight material, making it ideal for renewable energy applications. The corrosion resistance of aluminum profiles is exceptional, allowing them to withstand outdoor conditions and moisture exposure. This durability ensures the longevity and structural integrity of the profiles. Moreover, the recyclability of aluminum profiles makes them an environmentally friendly choice for the renewable energy industry. With the industry's focus on reducing carbon footprint and promoting sustainability, aluminum's recyclability plays a crucial role in achieving these objectives. Aluminum can be recycled repeatedly without losing its essential properties, reducing the necessity for extracting and processing new raw materials. Another advantage of aluminum profiles is their design flexibility, enabling the creation of intricate shapes and structures tailored to specific requirements. This versatility makes them suitable for various renewable energy applications, including solar panel frames, wind turbine components, and mounting systems. Additionally, the lightweight nature of aluminum profiles simplifies transportation and installation processes, resulting in cost and energy savings. In conclusion, the corrosion resistance, recyclability, design flexibility, and lightweight properties make aluminum profiles an excellent choice for the renewable energy industry. These characteristics contribute to the efficiency, durability, and sustainability of renewable energy systems, establishing aluminum profiles as a fitting material for this sector.

- Q: How do aluminum profiles perform in blast-resistant structures?

- Aluminum profiles are widely used in blast-resistant structures due to their exceptional performance characteristics. These profiles offer several advantages that make them suitable for such applications. Firstly, aluminum profiles possess excellent strength-to-weight ratio, which allows them to provide high structural integrity while keeping the overall weight of the structure relatively low. This is crucial in blast-resistant structures as it helps to minimize the impact of an explosion and reduce potential damage. Furthermore, aluminum profiles exhibit remarkable corrosion resistance, making them highly durable in harsh environments. This is particularly important in blast-resistant structures, where exposure to intense pressure waves, debris, and extreme temperatures may occur during an explosion. Moreover, aluminum profiles have excellent energy absorption capabilities. They can effectively absorb and dissipate the energy generated by a blast, thereby reducing the impact on the structure and enhancing its overall blast resistance. This feature is essential in ensuring the safety of occupants and preventing structural failure. Additionally, aluminum profiles offer excellent design flexibility, allowing architects and engineers to create complex and innovative structures. This versatility enables the construction of blast-resistant structures that can be tailored to specific requirements and design constraints. In summary, aluminum profiles perform exceptionally well in blast-resistant structures due to their high strength-to-weight ratio, corrosion resistance, energy absorption capabilities, and design flexibility. These qualities make them a preferred choice for architects and engineers when designing structures that need to withstand the forces generated by an explosion.

- Q: This question asks if aluminum profiles can be utilized in the construction of environmentally friendly buildings.

- <p>Yes, aluminum profiles can be used for green building applications. They are valued for their durability, recyclability, and energy efficiency. Aluminum is lightweight, which reduces the building's carbon footprint during transportation. It also has excellent thermal conductivity, allowing for better insulation and energy conservation. Additionally, aluminum can be recycled without losing its properties, contributing to a circular economy and reducing waste. These characteristics make aluminum profiles suitable for sustainable construction practices.</p>

- Q: Can aluminum profiles be used for stage and truss structures?

- Yes, aluminum profiles can be used for stage and truss structures. Aluminum is a lightweight and durable material that is commonly used in the construction of stage and truss systems. It has excellent strength-to-weight ratio, making it ideal for supporting heavy loads while minimizing the weight of the overall structure. Additionally, aluminum is corrosion-resistant, which is important for stage and truss structures that are often exposed to outdoor elements. Aluminum profiles can be easily assembled and disassembled, allowing for flexibility and ease of transportation. Overall, aluminum profiles are a popular choice for stage and truss structures due to their strength, lightweight nature, durability, and ease of use.

- Q: For example, 80*80 square tube 2.0mm thick. Or 38*25 square tube, 0.8mm thick, how to calculate the rice weight? Please tell the specific formula, urgent

- Length (you want to count the number of meters) * width (square tube expansion size) * high (wall thickness) * density (you this square tube material density, aluminum alloy gold density is more complex, generally in 2650~2750Kg/m3)1m * (0.08 * 4) * * 2750kg/m 0.002=0.00064m fand fand =1.76KGThen you 80*80 wall thickness of 2 square tubes, one meter is 1.76 kilogramsWindows and doors exchange group (228021644) hope to help you!

- Q: What are the weight capacities of aluminum profiles for shelving systems?

- The weight capacities of aluminum profiles for shelving systems can differ based on a variety of factors, including the profiles' dimensions, the shelving system's design, and the quality of the aluminum used. In general, aluminum profiles used for shelving systems can handle a substantial amount of weight. Nevertheless, it is important to acknowledge that the weight capacity of a shelving system also relies on other components like brackets, connectors, and the type of shelving material (e.g., wood, glass, or metal shelves) used. To obtain accurate weight capacity information, it is advisable to consult the manufacturer or supplier of the specific aluminum profile and shelving system. They can offer guidelines derived from their product specifications, engineering calculations, and testing. Additionally, proper installation, weight distribution, and regular maintenance are also vital factors in ensuring the overall strength and stability of a shelving system.

Send your message to us

Aluminum Profiles for Africa:Windows & Doors

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords