Aluminum Led Profiles AA1050 Mill-Finished Aluminum Coils D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA1050 Mill-Finished Aluminum Coils D.C Quality Used for Construction Description

AA1050 Mill-Finished Aluminum Coils D.C Quality Used for Construction has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

AA1050 Mill-Finished Aluminum Coils D.C Quality Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of AA1050 Mill-Finished Aluminum Coils D.C Quality Used for Construction

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

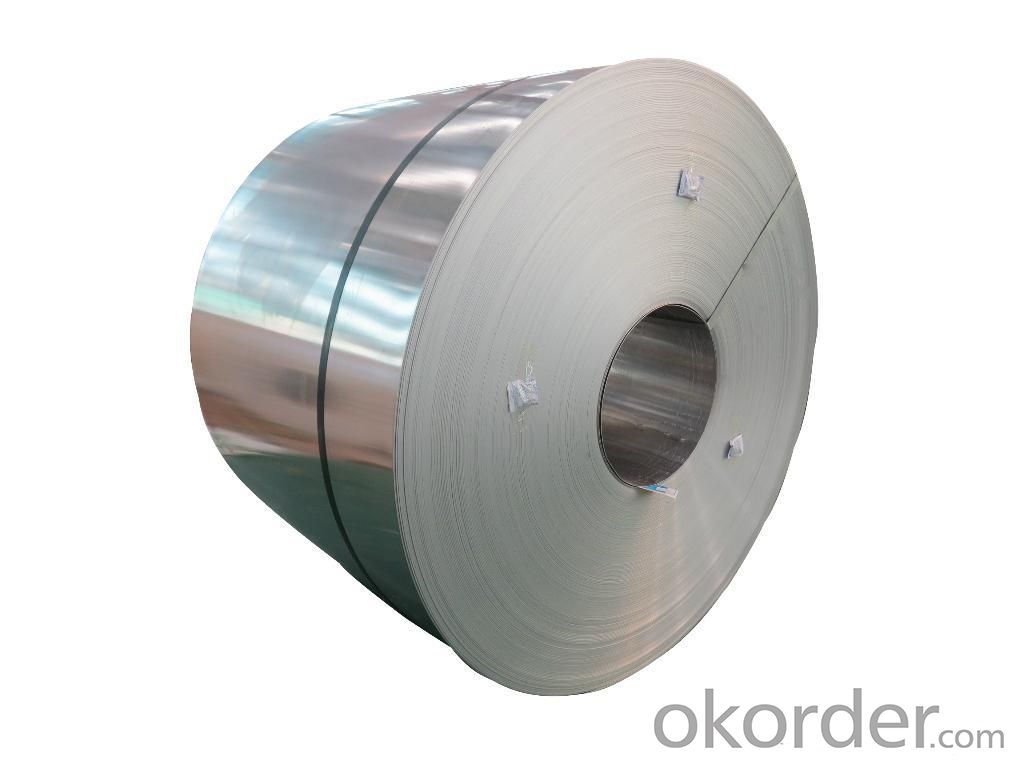

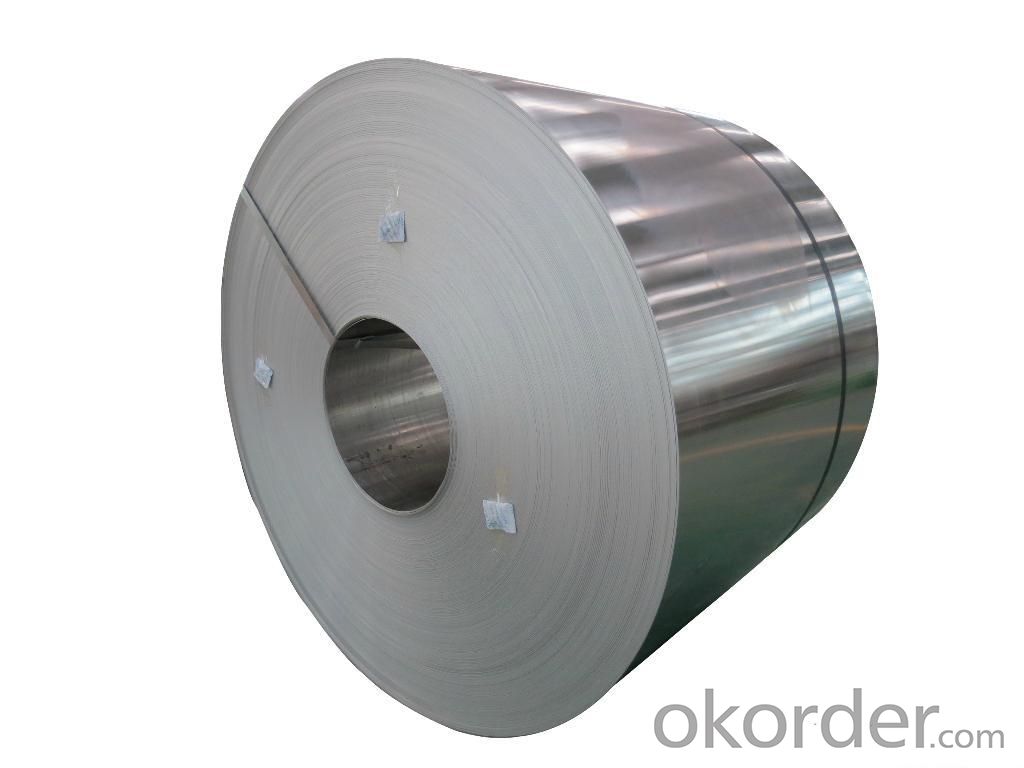

3.AA1050 Mill-Finished Aluminum Coils D.C Quality Used for Construction Images

4.AA1050 Mill-Finished Aluminum Coils D.C Quality Used for Construction Specification

Alloy | AA1050 |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of AA1050 Mill-Finished Aluminum Coils D.C Quality Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test AA1050 Mill-Finished Aluminum Coils D.C Quality Used for Construction.

B.When will you deliver the products?

AA1050 Mill-Finished Aluminum Coils D.C Quality Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: What are the impact resistance properties of aluminum profiles?

- Aluminum profiles have excellent impact resistance properties due to their inherent strength and durability. They can withstand high impact forces without deforming or breaking, making them suitable for various applications where impact resistance is crucial, such as automotive, construction, and aerospace industries. Additionally, aluminum profiles can absorb and distribute impact energy effectively, minimizing the risk of damage or injury.

- Q: I want to make my aluminum oxide, how much money is needed is a set of equipment? Please leave, thank you!

- Aluminum oxide brand and aluminum panel process and process, please

- Q: Can aluminum profiles be used for shopfitting and retail displays?

- Certainly, shopfitting and retail displays can absolutely utilize aluminum profiles. Aluminum, being a versatile material, possesses the advantageous combination of lightweight properties with remarkable strength, making it an ideal choice for constructing structures and fixtures in retail spaces. The customization and fabrication of aluminum profiles are effortlessly achievable, enabling the creation of tailored designs to meet specific requirements, thus allowing for the utmost flexibility in developing diverse display and shopfitting solutions. Moreover, the sleek and contemporary aesthetic offered by aluminum profiles is frequently sought after in retail environments. Furthermore, their exceptional durability and resistance to corrosion guarantee their enduring presence in areas with high foot traffic. Overall, due to their versatility, strength, customization options, and aesthetic appeal, aluminum profiles are an exceptional selection for shopfitting and retail displays.

- Q: This question asks for methods to ensure that the installation of aluminum profiles is both cost-effective and efficient.

- <p>To ensure the installation of aluminum profiles is cost-effective and efficient, follow these steps: 1) Plan carefully: Use accurate measurements and detailed plans to minimize waste and rework. 2) Use quality materials: Invest in high-quality aluminum profiles to reduce maintenance and replacement costs. 3) Employ skilled labor: Well-trained installers can complete the job faster and with fewer errors. 4) Optimize the installation process: Streamline the process to reduce time and labor costs. 5) Regular maintenance: Proper care and maintenance can extend the life of aluminum profiles, saving on replacement costs. 6) Compare suppliers: Shop around for the best prices and quality to minimize costs. 7) Use modular designs: Modular systems can be more efficient to install and easier to modify in the future.</p>

- Q: Are aluminum profiles suitable for gym equipment?

- Indeed, gym equipment can be made using aluminum profiles. Aluminum, being both lightweight and durable, can endure rigorous use and offer exceptional structural support. Its remarkable strength-to-weight ratio renders it perfect for gym equipment, granting effortless maneuverability while retaining stability and durability. Moreover, aluminum is resistant to corrosion, making it apt for environments abundant in moisture or humidity, like gyms or fitness centers. The versatility of aluminum profiles further allows for the customization of gym equipment to suit precise needs and requirements. Overall, aluminum profiles present a plethora of advantages for gym equipment, establishing them as an appropriate selection for fitness facilities.

- Q: Including the element parameters, the price and the difference between 6063, what is the use and so on!How about 6060 100/ meters? How much is the strength? How much is the price more than 6063?

- It has many valuable features: 1. heat treatment, high impact toughness, plasticity of missing insensitive.2. has excellent heat, can be squeezed into a high speed complex structure. The hollow thin wall. Various profiles or forged into the complex structure of the forging, quenching temperature range quenching, low sensitivity, extrusion and forging after stripping, as long as the temperature is higher than the quenching temperature. The quenching method available water or water in thin walled parts (6.

- Q: Are aluminum profiles suitable for high-temperature environments?

- Aluminum profiles are generally unsuitable for environments with high temperatures. Despite its excellent thermal conductivity and lightweight nature, aluminum has a lower melting point compared to other metals. At temperatures exceeding 400°C (752°F), aluminum begins to soften and can eventually lose its structural integrity. In high-temperature surroundings, aluminum profiles can experience deformation, distortion, or even complete failure. This can jeopardize the stability and functionality of any structure or system relying on aluminum profiles. Nevertheless, there exist specific aluminum alloys that are specifically engineered to withstand higher temperatures. Alloys like 6061 and 7075 have enhanced heat resistance and can endure higher temperatures without significant damage. These specialized alloys are commonly employed in applications requiring resistance to elevated temperatures, such as aerospace components or certain industrial processes. However, it is essential to thoroughly evaluate the temperature requirements of a given environment before utilizing aluminum profiles. In extremely high-temperature settings, alternative materials like steel or refractory metals may be more appropriate due to their higher melting points and superior heat resistance properties.

- Q: How do aluminum profiles perform in terms of water resistance?

- The natural properties of aluminum profiles generally result in good water resistance. This is because the metal itself is resistant to corrosion, meaning it does not easily rust or degrade when exposed to water. Furthermore, the water resistance capabilities of aluminum profiles can be improved through the application of coatings or anodization processes. These treatments create a protective layer that prevents water from penetrating the metal, thereby reducing the risk of damage or deterioration over time. However, it is important to consider that the water resistance of aluminum profiles may vary depending on factors such as the specific alloy used, the type of surface treatment applied, and the maintenance practices employed. To ensure optimal water resistance performance, it is recommended to regularly clean the profiles and properly seal any joints.

- Q: Explain the positive environmental impacts of utilizing recycled aluminum in the construction industry.

- <p>Using recycled aluminum in construction offers significant environmental benefits. It conserves natural resources by reducing the need for mining new bauxite, the primary source of aluminum. This reduction in mining decreases habitat destruction, water pollution, and soil erosion. Additionally, recycling aluminum saves energy, as it requires only 5% of the energy needed to produce aluminum from raw materials. This energy conservation leads to lower greenhouse gas emissions and air pollution. Moreover, the use of recycled aluminum reduces landfill waste, as less material ends up in landfills. Overall, it promotes a more sustainable and eco-friendly construction process.</p>

- Q: What are the different bending machines or tools used for aluminum profiles?

- There are several bending machines and tools that are commonly used for aluminum profiles. These tools are designed to manipulate aluminum profiles into various shapes and angles to meet specific project requirements. 1. Manual Tube Bender: This is a hand-operated bending tool that is commonly used for smaller aluminum profiles. It consists of a lever and a bending shoe that is used to bend the profile manually. 2. Hydraulic Tube Bender: This machine is equipped with hydraulic power to bend larger and thicker aluminum profiles. It offers more precision and control compared to manual benders, making it suitable for industrial applications. 3. CNC Tube Bending Machine: This is a computer-controlled machine that uses a combination of hydraulic power and computer programming to accurately bend aluminum profiles. It can produce complex and precise bends, making it ideal for high-volume production and intricate designs. 4. Roll Bending Machine: This machine is specifically designed for bending aluminum profiles into curved shapes. It consists of three rolls, with the profile passing through the middle roll while the other two rolls apply pressure to bend it into the desired curve. 5. Mandrel Bender: This tool is used for bending aluminum profiles without deforming or collapsing the inner diameter. It uses a mandrel (a rod inserted into the profile) to support the inner wall during the bending process, ensuring a smooth and consistent bend. 6. Rotary Draw Bender: This machine uses a combination of bending dies and a rotating arm to produce accurate and repeatable bends in aluminum profiles. It is commonly used for bending tubes and pipes, but can also be adapted for aluminum profiles. These bending machines and tools offer different levels of precision, control, and production capacity, allowing manufacturers and fabricators to choose the most suitable option based on their specific needs and requirements.

Send your message to us

Aluminum Led Profiles AA1050 Mill-Finished Aluminum Coils D.C Quality for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords