Aluminum Honeycomb Sheets 6061/6082-T6 for Mould - Aluminum Alloy Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Alloy Plate 6061/6082-T6 for Mould Description:

The alloy 6061 has very good welding characteristics and may be welded by all of the common welding techniques. Gas tungsten arc welding is generally used for thin sections and gas metal arc welding is used for heavier sections.Commonly used in the manufacture of heavy-duty structures requiring good corrosion resistance, truck and marine components, railroad cars, furniture, tank fittings, general structural and high pressure applications, wire products, and in pipelines.

2.Main Features of Aluminum Alloy Plate 6061/6082-T6 for Mould:

Good mechanical properties.

Easy processing, wearability.

Corrosion resistance

Resistance to oxidation.

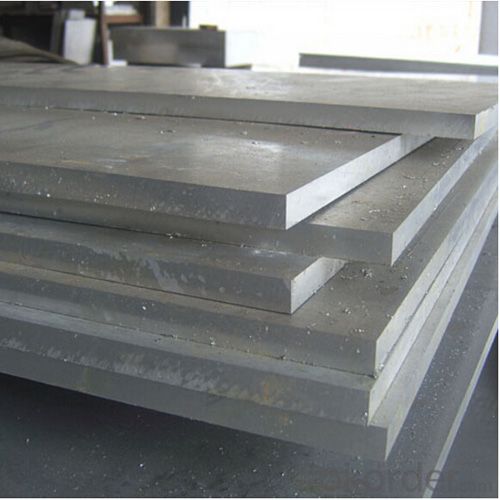

3. Aluminum Alloy Plate 6061/6082-T6 for Mould Images:

4. Aluminum Alloy Plate 6061/6082-T6 for Mould Specification:

| Aluminium sheet | |||||

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: 1 ton of aluminium=______ tons of Alumina

- Aluminium is a reactive metal and it is hard to extract it from its ore, aluminium oxide (Al2O3). Direct reduction, with carbon for example, is not economically viable since aluminium oxide has a melting point of about 2000 °C. Therefore, it is extracted by electrolysis — the aluminium oxide is dissolved in molten cryolite and then reduced to the pure metal. By this process, the actual operational temperature of the reduction cells is around 950 to 980 °C. Cryolite was originally found as a mineral on Greenland, but has been replaced by a synthetic cryolite. Cryolite is a mixture of aluminium, sodium, and calcium fluorides: (Na3AlF6). The aluminium oxide (a white powder) is obtained by refining bauxite, which is red since it contains 30 to 40% iron oxide. This is done using the so-called Bayer process. Previously, the Deville process was the predominant refining technology. The electrolytic process replaced the W?hler process, which involved the reduction of anhydrous aluminium chloride with potassium. Both of the electrodes used in the electrolysis of aluminium oxide are carbon. Once the ore is in the molten state, its ions are free to move around. The reaction at the negative cathode is Al3+ + 3 e- → Al Here the aluminium ion is being reduced (electrons are added). The aluminium metal then sinks to the bottom and is tapped off. At the positive electrode (anode) oxygen gas is formed: 2 O2- → O2 + 4 e- This carbon anode is then oxidised by the oxygen. The anodes in a reduction must therefore be replaced regularly, since they are consumed in the process: O2 + C → CO2 So, as you can see, the exact tonnage required to produce 1 ton of aluminum is very sketchy at best...

- Q: Can aluminum sheets be used for sound barriers?

- Yes, aluminum sheets can be used for sound barriers. Aluminum is a lightweight and durable material that can effectively block and absorb sound waves, making it an ideal choice for soundproofing applications. Aluminum sheets can be installed in various forms, such as solid panels or perforated sheets, to create effective sound barriers in residential, commercial, and industrial settings. The thickness and design of the aluminum sheets can be customized to meet specific soundproofing requirements. Additionally, aluminum is resistant to corrosion, making it suitable for outdoor applications where sound barriers may be exposed to harsh weather conditions. Overall, aluminum sheets provide a cost-effective and efficient solution for reducing noise levels and creating quieter environments.

- Q: Im wondering as to how i darken the slide and frame of an airsoft 1911 pistol. I polished off all the black paint and exposed the chromish aluminum. I have some ideas to darken the metal but not sure. Maybe using olive oil and heating it up but im afraid i might warp the metal. I want it to come out sort of like a greyish gunmetal. Anybody know of a good process to give that worn out war like effect to the gun without painting it?

- i have been surfing more than 4 hours today seeking the answer to the same question, and I haven't found a more interesting debate like this. it is pretty worth enough for me.

- Q: I have heard that drinking from aluminum cans is bad for our health. However, I have learned that today's 'aluminum' cans are actually more like a plastic can due to all the coatings, etc. Do we really have any risks associated with regular cans?

- Aluminum cans have a thin plastic lining. This lining prevents the leeching of aluminum into the liquid it contains. The big health scare over aluminum was over research done on Alzheimer's disease. Autopsies revealed a higher concentration of aluminum in the brain of some patients with Alzheimer's. It is unknown whether aluminum was a possible culprit, or the diseased tissue for some reason just held onto more aluminum. Further research has not been able to duplicate these results; autopsies of some patients show no increased levels of aluminum. [1], [2], [3], [4] Aluminum toxicity is rare and usually found in patients with renal failure. [5] The amount of aluminum you would be exposed to even if cans were not coated wouldn't cause you any harm.

- Q: What are the advantages of using aluminum sheets in the packaging industry?

- Aluminum sheets have numerous benefits in the packaging industry. To begin with, their lightweight composition makes them ideal for packaging purposes. Unlike steel or glass, aluminum is much lighter, making it easier to handle and transport. This weight advantage also reduces shipping costs, as less fuel is needed for transportation. In addition, aluminum sheets provide excellent barrier properties. They effectively block out oxygen, moisture, and light, all of which can compromise the quality and freshness of packaged goods. This barrier extends the shelf life of products, ensuring they reach consumers in optimal condition. Moreover, aluminum sheets are highly durable and resistant to corrosion. This durability guarantees that packaged items remain protected, even in challenging environmental conditions. They are also resistant to temperature fluctuations, maintaining the integrity of the packaging material without warping or deforming. Furthermore, aluminum is a highly recyclable material. Its use in the packaging industry promotes sustainability and reduces the carbon footprint. Aluminum packaging is easily recyclable and reusable, minimizing the need for new materials and reducing waste. Additionally, aluminum sheets offer versatility in terms of design and customization. They can be easily molded and shaped into various packaging formats, including cans, trays, foils, and pouches. This flexibility enables packaging manufacturers to create innovative and visually appealing solutions that cater to the unique needs and preferences of different industries and consumers. Overall, the advantages of using aluminum sheets in the packaging industry encompass their lightweight nature, excellent barrier properties, durability, recyclability, and versatility. These benefits establish aluminum sheets as the preferred choice for packaging manufacturers, ensuring the protection, preservation, and attractiveness of packaged products.

- Q: Are aluminum sheets suitable for chemical processing applications?

- Aluminum sheets are a great choice for chemical processing applications. They are widely used in various industries, including chemical processing, due to their versatility. One of the reasons aluminum is preferred is because it has excellent corrosion resistance properties. This makes it ideal for applications that involve exposure to chemicals and corrosive environments. Aluminum sheets can resist many acids and alkalis, including common chemicals like sulfuric acid, hydrochloric acid, and sodium hydroxide. The reason aluminum is so resistant to corrosion is because of the thin oxide layer that forms on its surface. This layer acts as a barrier against chemical attacks and can quickly reform if damaged, providing continuous protection to the metal underneath. Additionally, aluminum is lightweight, has high thermal conductivity, and can be easily shaped and sized, making it a popular choice for chemical processing equipment and components. In chemical processing applications, aluminum sheets are often used for storage tanks, heat exchangers, piping systems, and other equipment that comes into contact with chemicals. They can withstand high temperatures and pressures, making them suitable for various processing conditions. Furthermore, aluminum is non-toxic, non-magnetic, and has excellent electrical conductivity, which can be advantageous in certain chemical processes. However, it's important to consider the specific chemical environment and conditions when choosing aluminum sheets for chemical processing applications. Some aggressive chemicals, like strong bases or highly oxidizing acids, may require additional protection or alternative materials. It's recommended to consult with experts or engineers who are familiar with the specific chemical processes and conditions to ensure that aluminum sheets are suitable for a particular application.

- Q: How do aluminum sheets perform in terms of water resistance?

- Aluminum sheets possess exceptional water resistance qualities. Thanks to the natural formation of an oxide layer on its surface, aluminum exhibits a high level of resistance to corrosion and effectively hinders water penetration. This oxide layer, referred to as aluminum oxide, acts as a protective barrier, preventing the interaction between aluminum and water molecules. Moreover, aluminum sheets can receive additional surface treatments, such as anodizing or coating, to further enhance their water resistance. These treatments result in a thicker and more durable oxide layer, significantly enhancing the sheets' resistance against water damage, moisture, and rust. In summary, aluminum sheets are a dependable option for applications that necessitate water resistance, guaranteeing enduring performance in diverse environments.

- Q: Can aluminum sheets be bent into complex shapes?

- Yes, aluminum sheets can be bent into complex shapes due to their malleability and ductility. With the appropriate tools and techniques, aluminum sheets can be formed into intricate and customized designs, making them versatile for various applications.

- Q: What are the common aluminum sheets and the best ones?

- Look, what's your use for it?. Aluminum alloy is divided into 1000 series and 9000 series, each series has the characteristics and uses of each series. The most commonly seen aluminum plate is 1060 (pure aluminum), 2024, 5052, 6061, 6063, 7075, 6083, 5082 aluminum alloy plate. The best should be imported 7000 series, but also depends on your use to say.

- Q: Can aluminum sheets be painted?

- Yes, aluminum sheets can be painted. However, it is important to properly prepare the surface by cleaning, sanding, and using a primer specifically formulated for metal surfaces to ensure good adhesion of the paint.

Send your message to us

Aluminum Honeycomb Sheets 6061/6082-T6 for Mould - Aluminum Alloy Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords